Flux-cored wire for electrogas arc welding

A gas-electric vertical welding and welding wire technology, used in welding/welding/cutting objects, welding equipment, welding media, etc. Excellent performance and improved workability

Active Publication Date: 2009-04-01

JFE STEEL CORP +1

View PDF1 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] However, if simply adding alloy components to the existing welding wire to increase the strength, the viscosity of the slag during welding will increase, and the workability wil

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention provides a flux-cored wire for electrogas welding, which has excellent operability in single-electrode electrogas welding of thick steel plate, and additionally can obtain a welding metal that has high strength and excellent impact property. The flux-cored wire for electrogas welding comprises the following components with the percent by weight: 0.03-0.07wt% of C, 0.3-0.6wt% of Si, 1.8-2.0wt% of Mn, 0.9-1.2wt% of Ni, 0.3-0.8wt% of Mo, 0.10-0.27wt% of Ti, 0.008-0.014wt% of B, 0.15-0.30wt% of Mg, less than 0.05wt% of Al, less than 0.025wt% of P, less than 0.025wt% of S, 1.0-2.0wt% of sinter forming agent, and 0.4-0.7wt% of F in the sinter forming agent.

Description

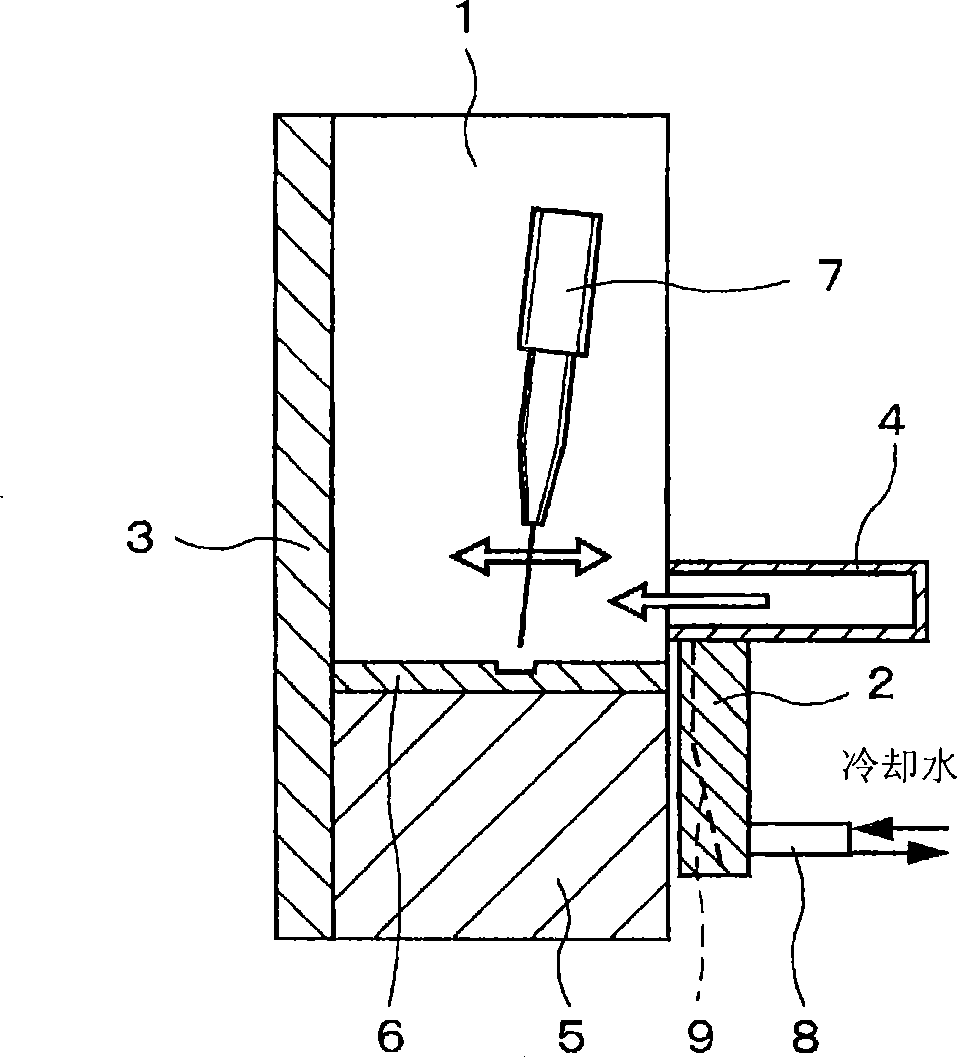

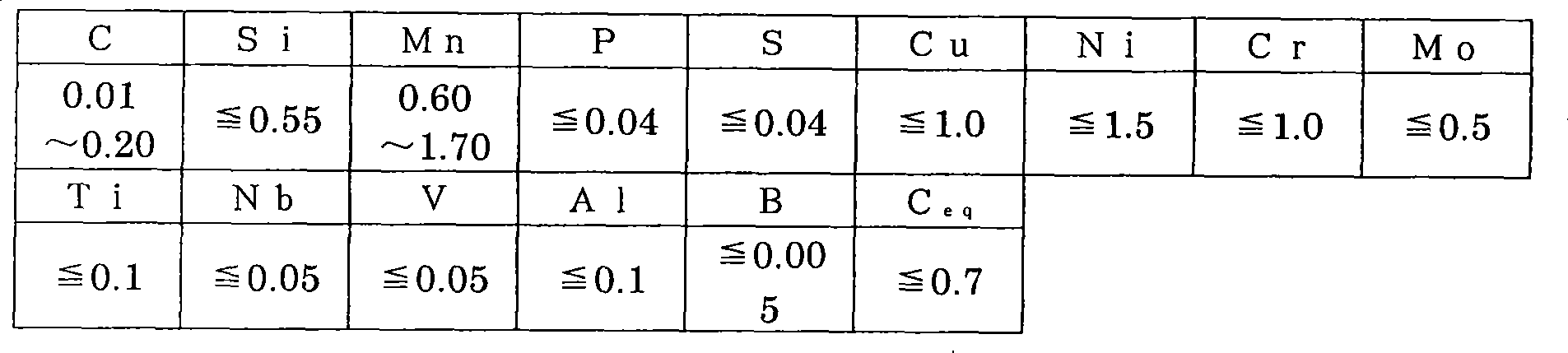

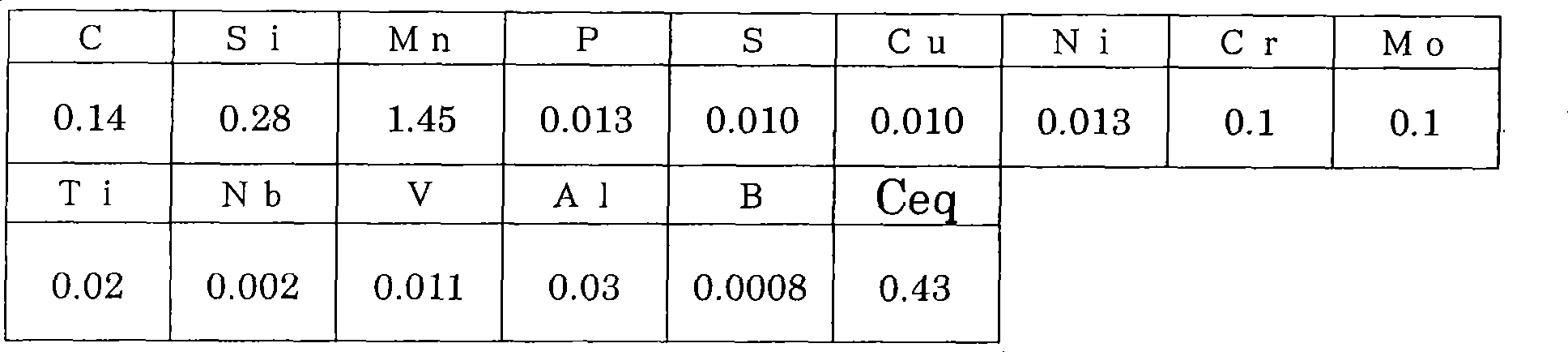

technical field [0001] The present invention relates to a single-electrode gas-electric vertical welding flux-cored wire capable of vertical one-pass welding of thick steel plates such as YP 460 steel. Background technique [0002] As a high-efficiency vertical welding process, gas-electric vertical welding is used in a wide range of fields such as ships, oil storage tanks, and bridges. Recently, the economic and industrial development of China and East Asian countries has been remarkable, and along with the increase in the volume of logistics, container ships have been rapidly increased in size for the purpose of efficient transportation of container cargo. [0003] With the increase in size of container ships, the thickness of side shell plating and hatch coaming is advancing. When the load capacity of the container is 8000TEU, if the yield strength (yield strength) 390N / mm 2 For steel, the application thickness is about 80mm. On the other hand, steel has a yield stren...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K35/368

CPCB23K35/3073B23K35/3602B23K35/406B23K2103/02C22C38/02C22C38/42C22C38/44C22C38/50C22C38/54C22C38/58

Inventor 角博幸石崎圭人桥本哲哉中野利彦

Owner JFE STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com