Electrogas welding arc length controller based on FPGA (Field Programmable Gate Array)

A gas-electric vertical welding and controller technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

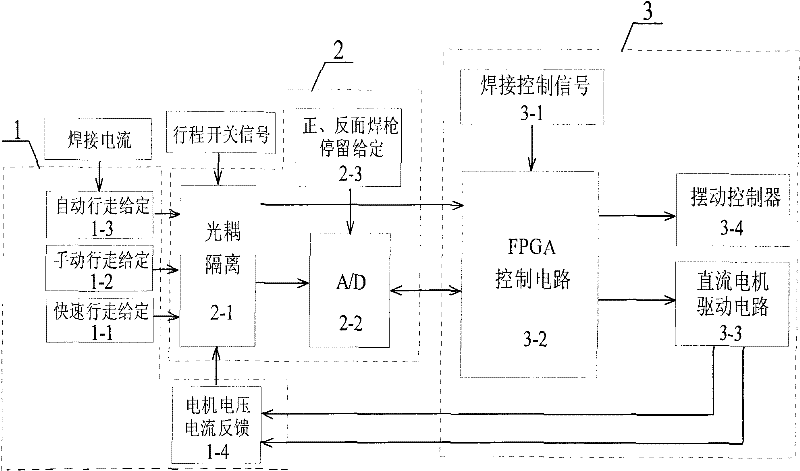

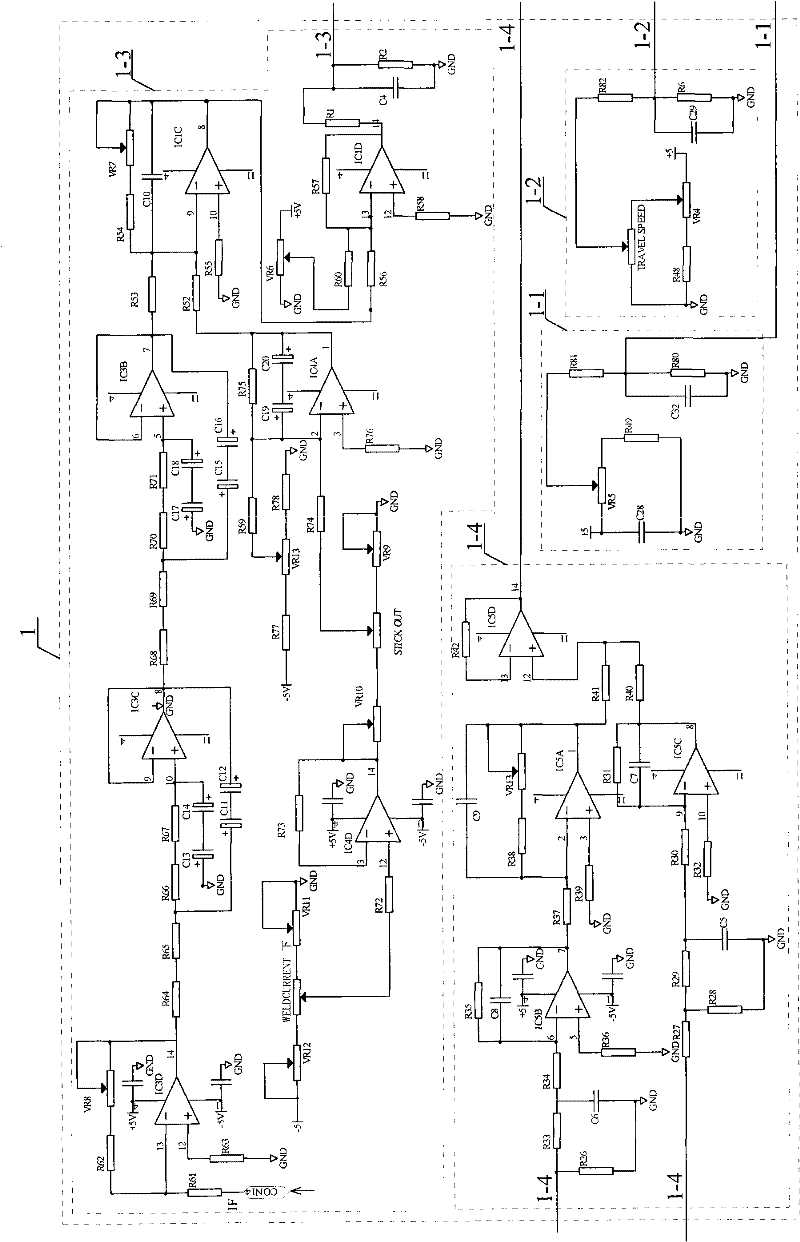

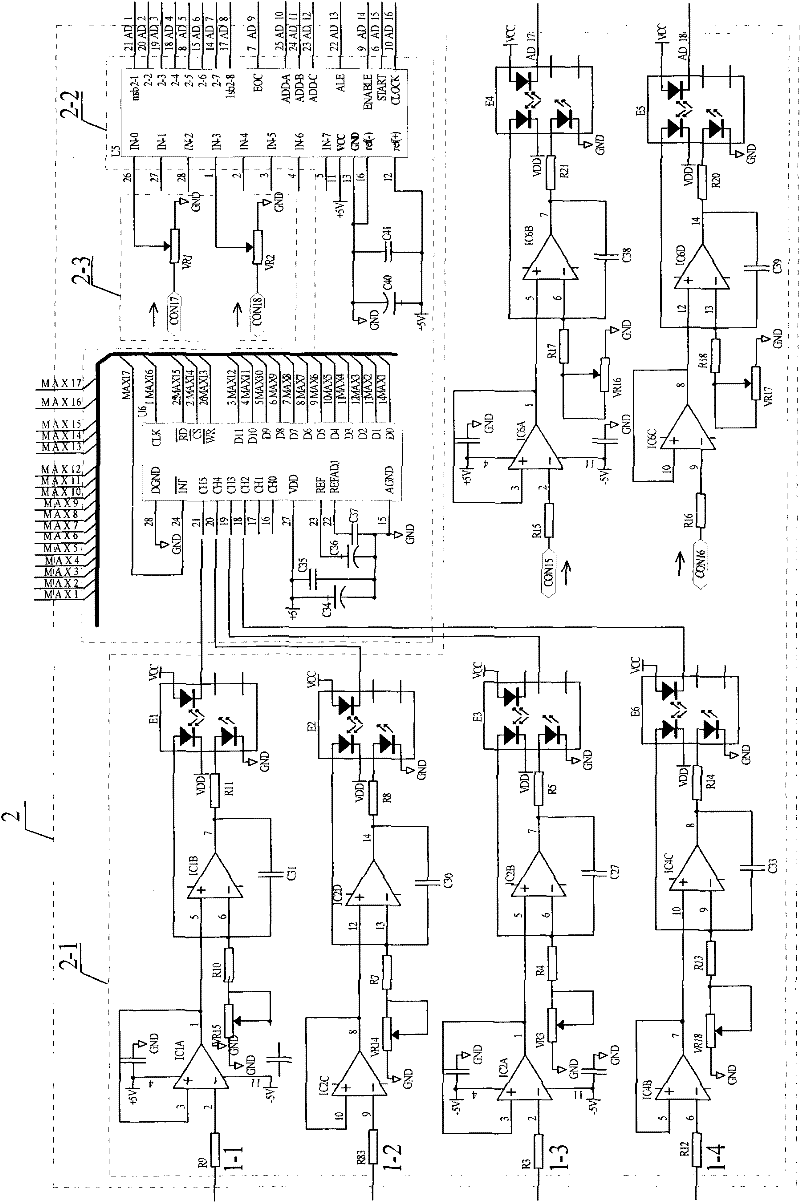

[0018] Below in conjunction with accompanying drawing, the technical scheme of invention is described in detail:

[0019] Such as figure 1 As shown, the gas-electric vertical welding arc length controller based on FPGA is characterized in that it includes: three-way trolley walking given circuit (1-1~1-3), motor voltage negative feedback current positive feedback circuit (1-4 ), isolated optocoupler circuit (2-1), AD conversion circuit (2-2), front and back welding torch stay given circuit (2-3), welding control signal circuit (3-1), FPGA control circuit (3- 2), DC motor drive circuit (3-3) and welding torch swing control circuit (3-4), wherein:

[0020] The sampling welding current signal is sent to the automatic walking given circuit (1-3);

[0021] The fast walking given circuit (1-1), the manual walking given circuit (1-2) and the automatic walking given circuit (1-3) pass through the optocoupler isolation circuit (2-1) respectively, and then send the signal to AD Conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com