Flux-cored wire for electrogas welding and electrogas welding metal

A gas-electric welding and welding wire technology, applied in the field of 1-electrode gas-electric welding flux-cored wire and gas-electric welding metal, can solve the problems of difficulty in obtaining elongation, deterioration of toughness, and high tensile strength, and achieve excellent welding workability, good impact value, The effect of high elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

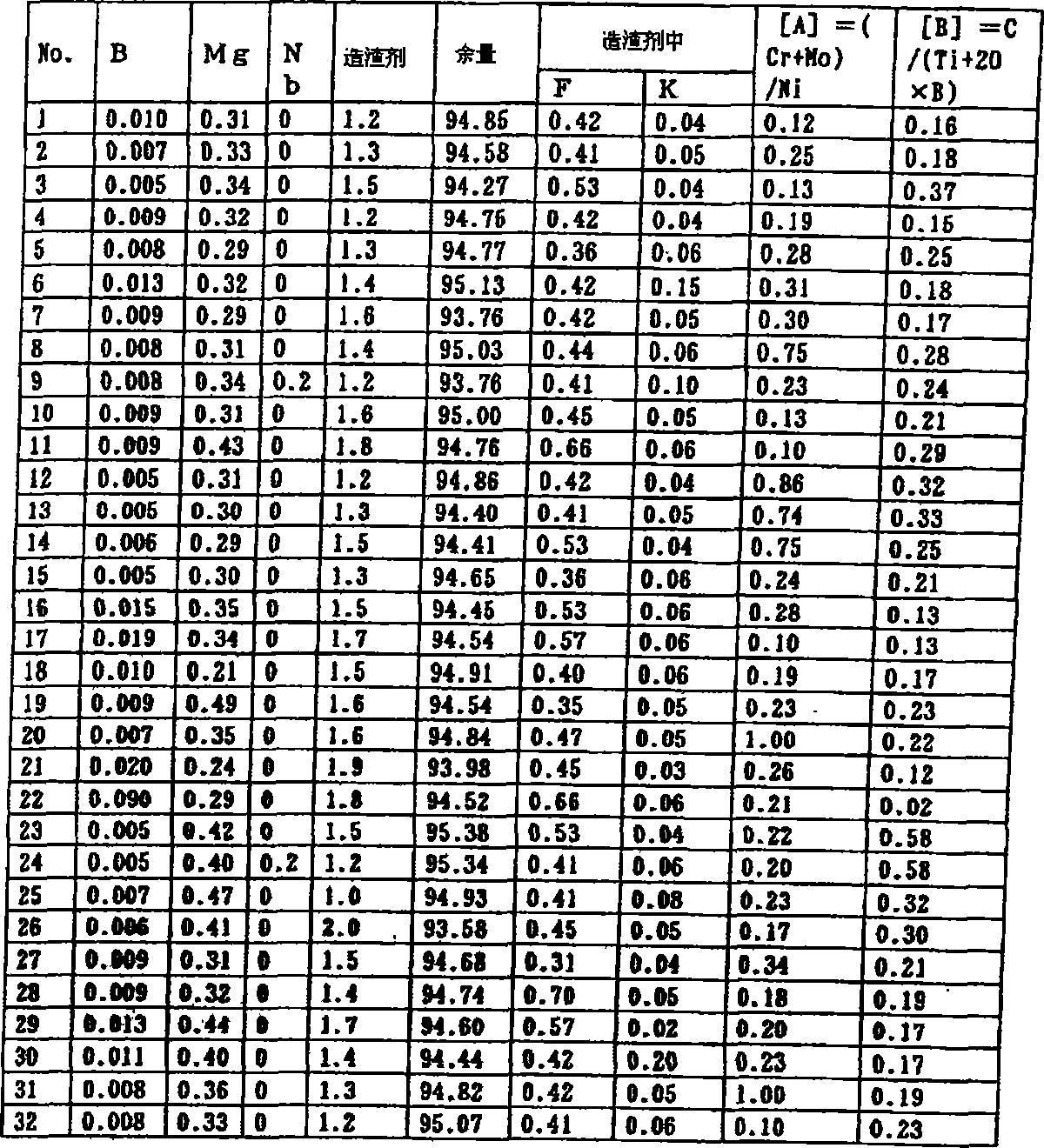

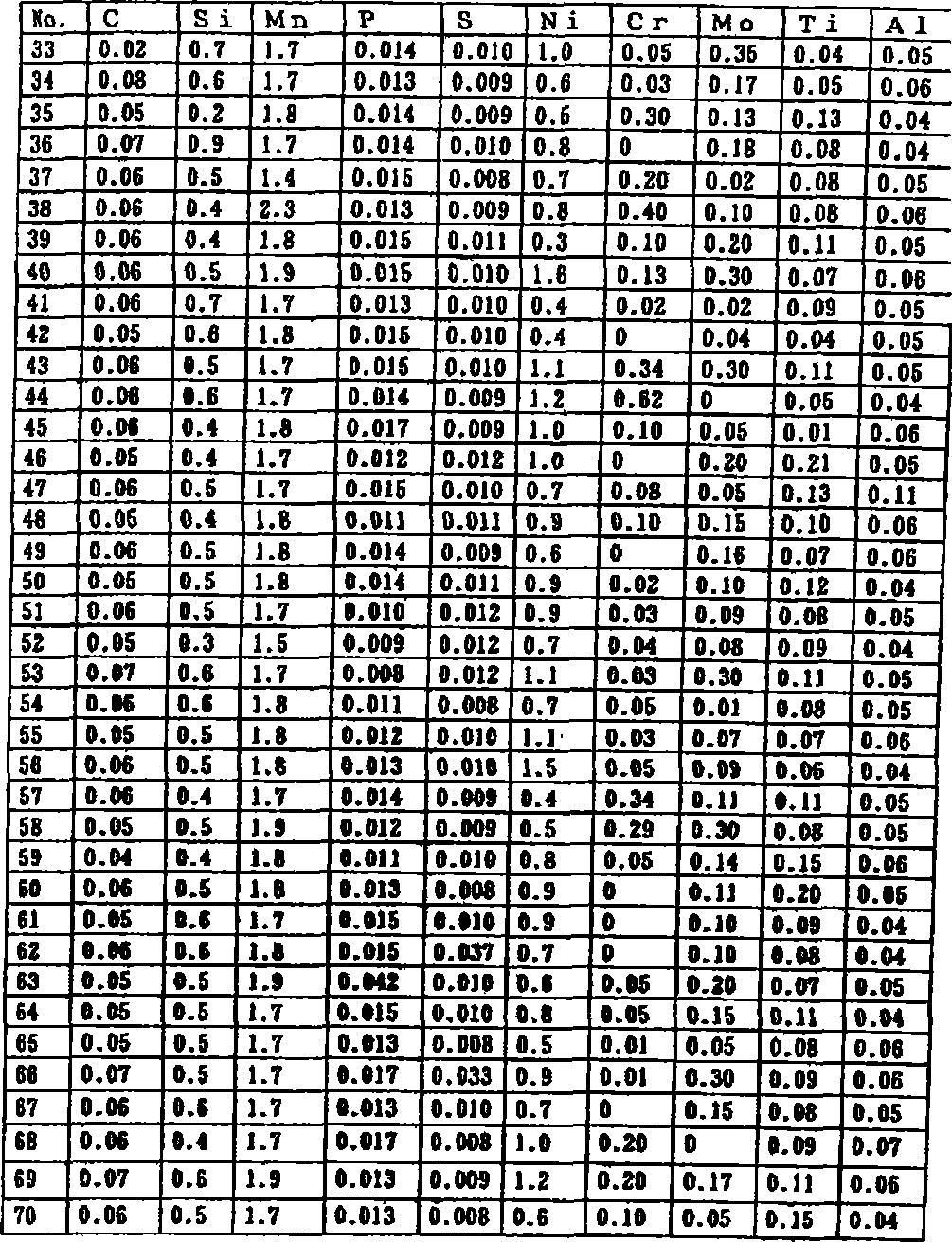

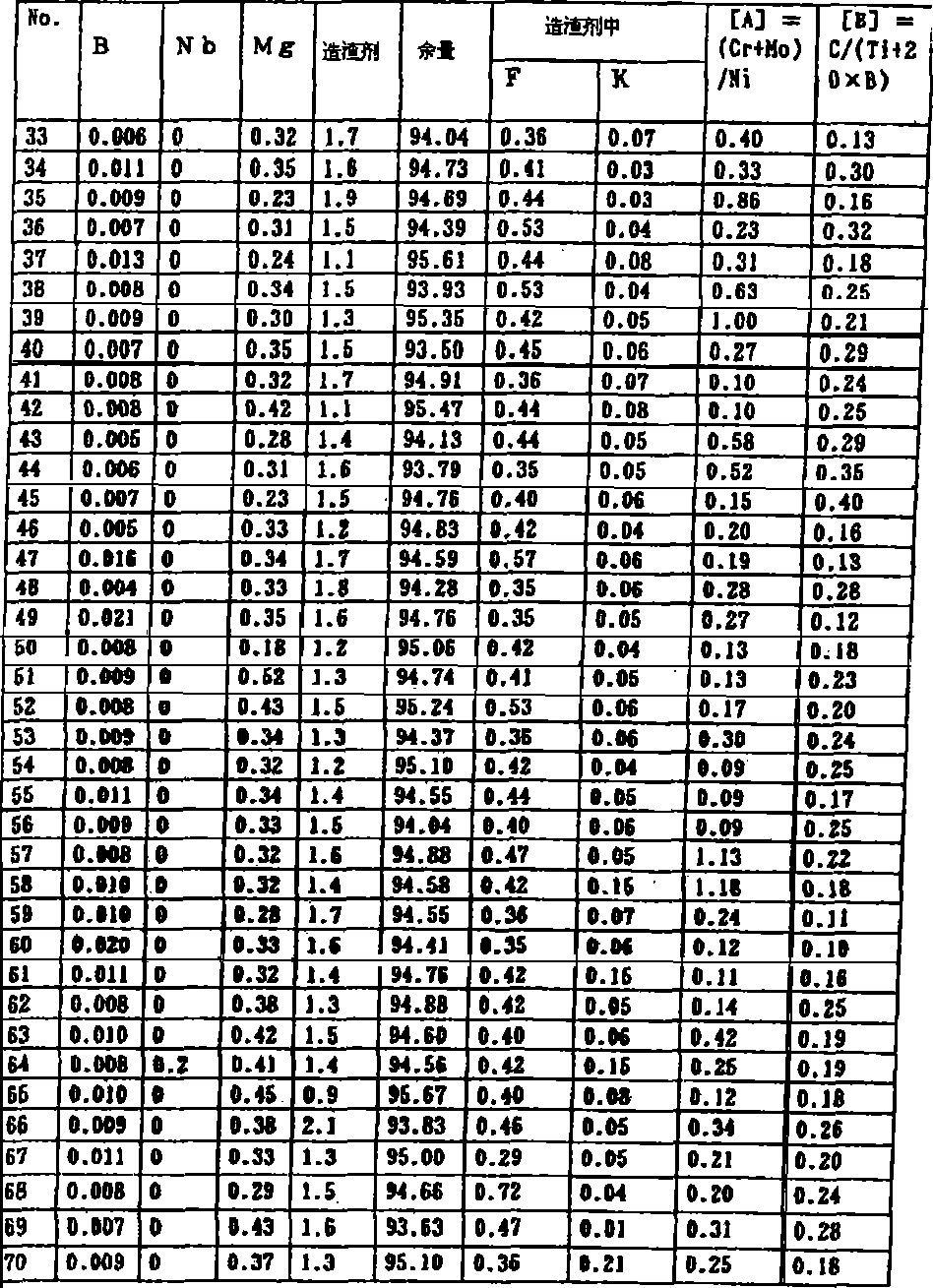

Examples

Embodiment Construction

[0050] Conventionally, Ni has been mainly added to the welding wire to improve the strength reduction and toughness of the weld metal due to the increase in welding heat energy due to thickening. Therefore, even when the plate thickness of the welded plate is as thick as 60 mm, it has been confirmed that the amount of Ni in the gas welding metal becomes 2% by mass or more. However, if a welding wire with a large Ni content is used to weld a relatively thin 25mm welded plate, the heat energy will decrease and the hardenability will increase. direction, but the strength becomes too high due to an excessively large alloy composition mainly composed of Ni, and a tendency to deteriorate the toughness and make it difficult to obtain elongation is confirmed. Therefore, the inventors of the present invention have developed a component that can effectively deal with the decrease in strength and the deterioration of toughness even if the amount of the alloy component is small when the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com