Self-adaptation anti-interference control system for electrogas welding automatic welder

An automatic welding machine, gas-electric vertical welding technology, applied in arc welding equipment, high-frequency current welding equipment, welding power sources, etc., can solve the problems of insufficient application and development, no elimination effect, and resource consumption. , to achieve good economic and social significance, eliminate external interference, and ensure the effect of welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

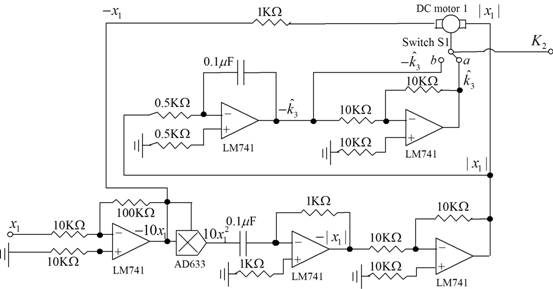

[0010] In the control box of the gas-electric vertical welding automatic welding machine, the current signal for the system , design the following adaptive anti-interference circuit: Here, LM741 is an operational amplifier, AD633 is a multiplier with an output factor of 0.1, and the resistance values are respectively , , , , the value of the capacitance is , the motor can choose Z2 series DC motor.

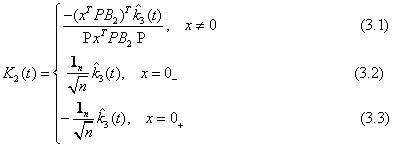

[0011] First, the current signal in the welding machine control box Use the operational amplifier LM741 to invert and amplify by 10 times, and then use the multiplier AD633 and the operational amplifier twice to make the signal an absolute positive phase signal, and use this absolute positive phase signal and the inverting signal of the original signal In comparison, if the original signal is a positive-phase signal, the motor has current passing through it, and the electric motor makes the switch S1 and point b connected (corresponding to formulas 3.1 and 3.3), and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com