Trunk lid welding structure and method

A technology for welding structures and trunk lids, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as welding bump grinding difficulties, welding distortion, and welding difficulties between the rear taillight mounting plate and the outer panel of the trunk lid, etc. To achieve the effect of ensuring the accuracy of welding and the consistency of quality, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

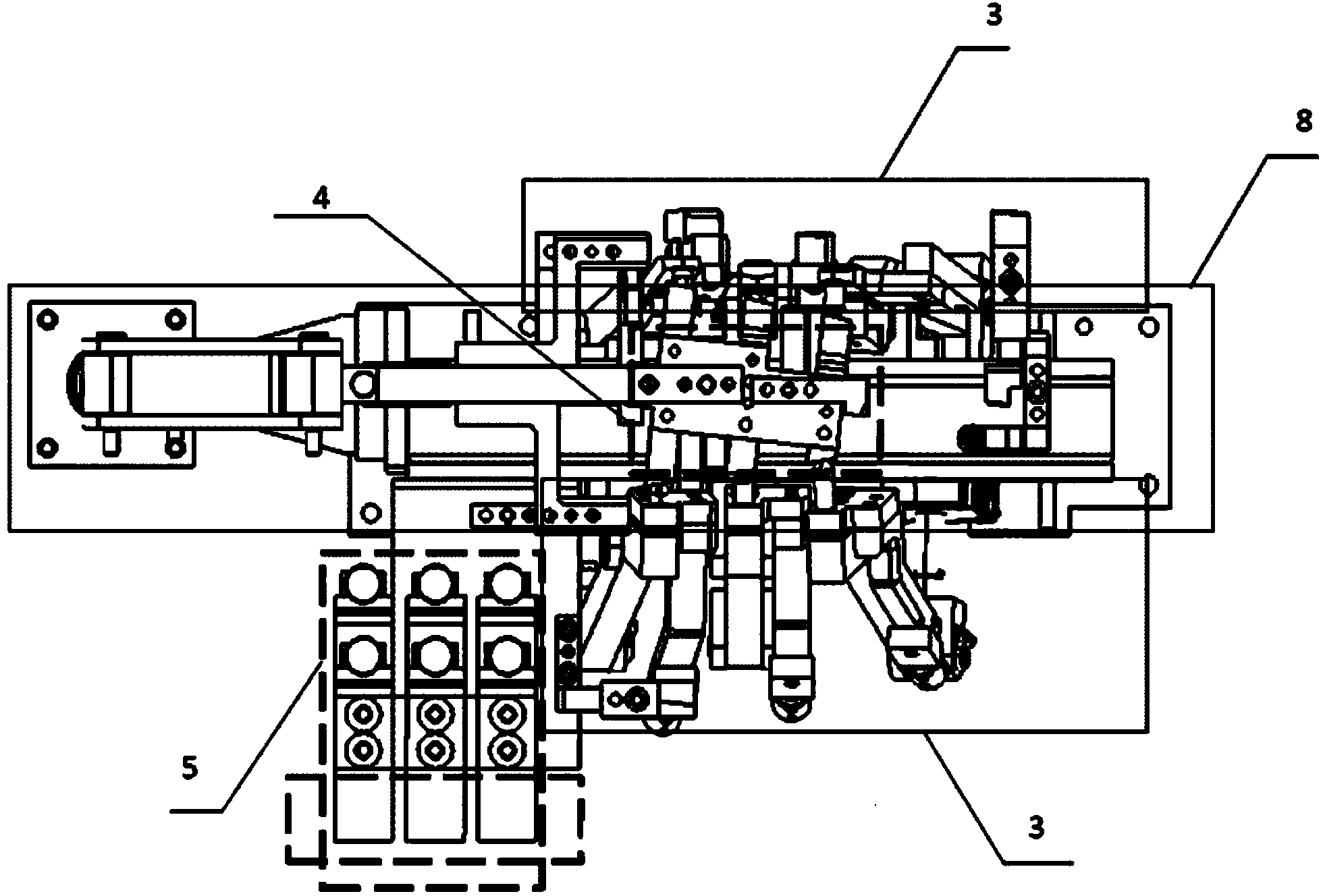

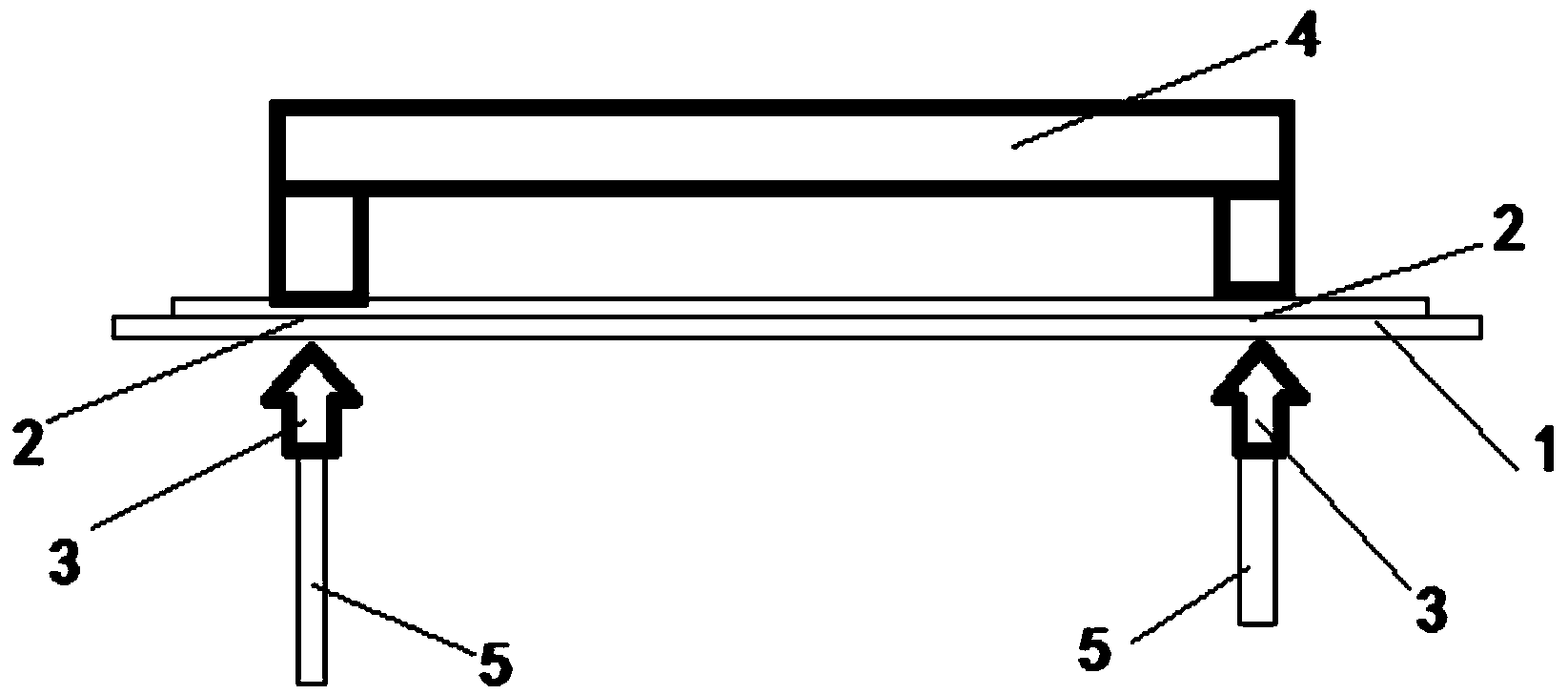

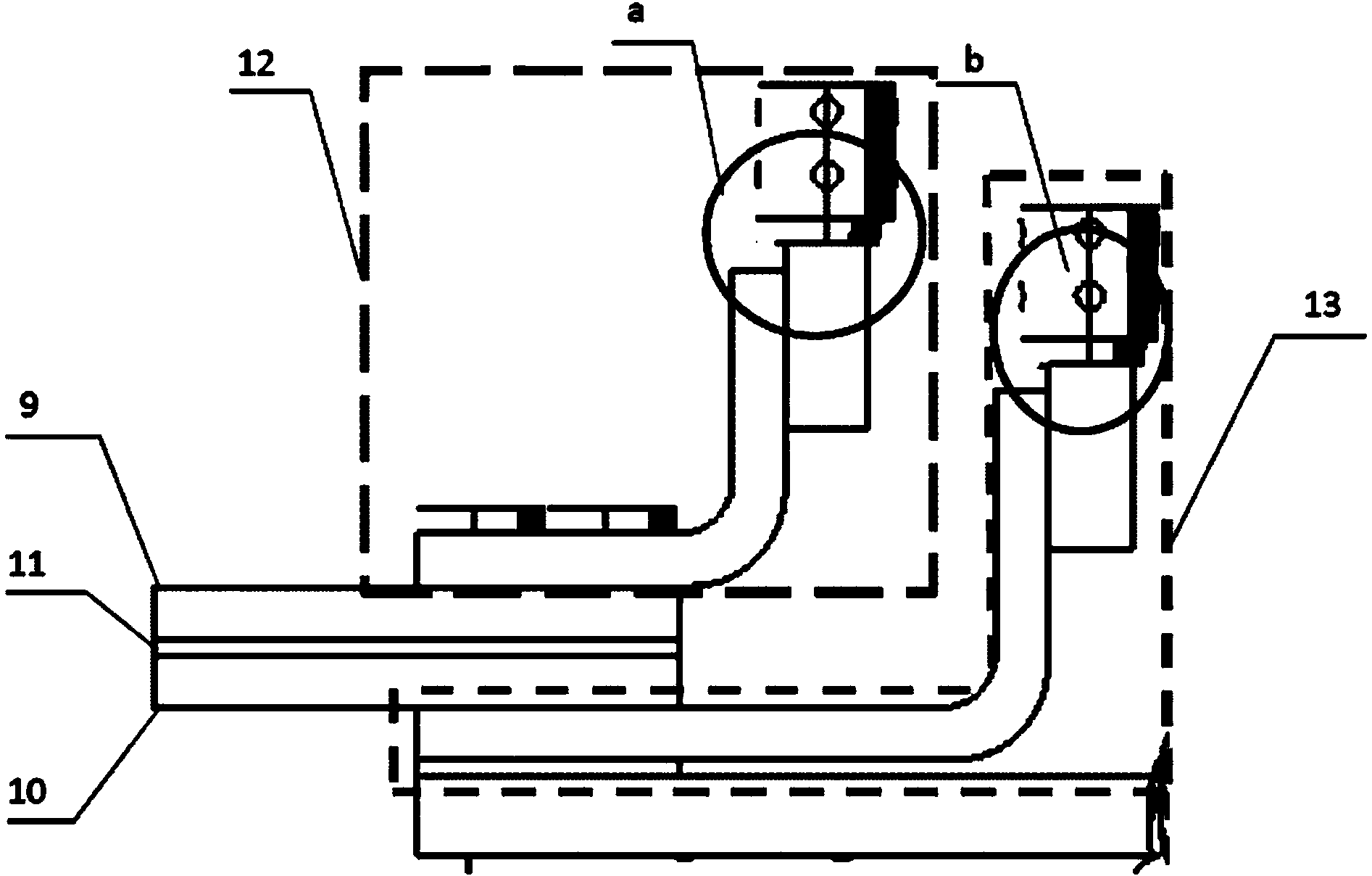

[0018] like Figures 1 to 3 As shown, the present invention provides a trunk lid welding structure, which includes a fixture body 8, on which a welding tongs part 3, a clamping part 4 and a copper bar part 5 are installed, and the plate to be welded 1 is placed on the The clamping part 4 and the welding tongs part 3 are clamped and positioned, and the copper bar part 5 is electrically connected to the welding tongs part 3, wherein: the clamping part 4 is connected to the welding tongs part 3 are electrically connected through the clamped part 2 of the plate to be welded 1, and at the clamped part 2, a welding point is formed through the electrical connection to form a welding connection of the plate to be welded 1 .

[0019] In the present invention, the clamping part is also used as a contact point for electric welding, which ensures accurate positioning and precise contact fit during welding, and ensures the accuracy of welding and the consistency of quality.

[0020] Wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com