Double-layer cable erecting method

A cable, double-layer technology, applied in the field of underground power distribution equipment erection in mines, can solve problems such as affecting normal production, hidden dangers, cable crash, etc., so as to reduce the number of electric welding, improve safety, and reduce the number of repairing cables. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Below in conjunction with accompanying drawing, the present invention is described in detail.

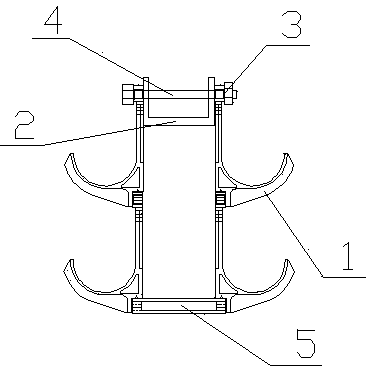

[0008] A method for erecting double-layer cables, fixing a hanger 2 and two rows of cable hooks 1 connected to the hanger 2, each row of cable hooks 1 is composed of two single cable hooks connected, two rows of cable hooks The hook heads are outwardly connected to both sides of the hanger 2 respectively. A support member 5 is arranged between the lowermost ends of the two rows of cable hooks. The length of the support member 5 is consistent with the width of the hanger 2 . When installing and using, the hanger part at the top of the back-to-back cable hook is close to the anchor rod at the top of the mine roadway, fixed with bolts, and the back-to-back cable hook is fixedly connected to the top of the mine roadway.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com