Preparation method for crystalline silicon solar cell nanometer transparent buried gate electrode

A technology of solar cells and buried gate electrodes, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of anti-reverse carrier collection rate, nano transparent electrodes and silicon chip ohmic contact problems that have not been mentioned, and achieve Excellent carrier collection efficiency, low cost, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

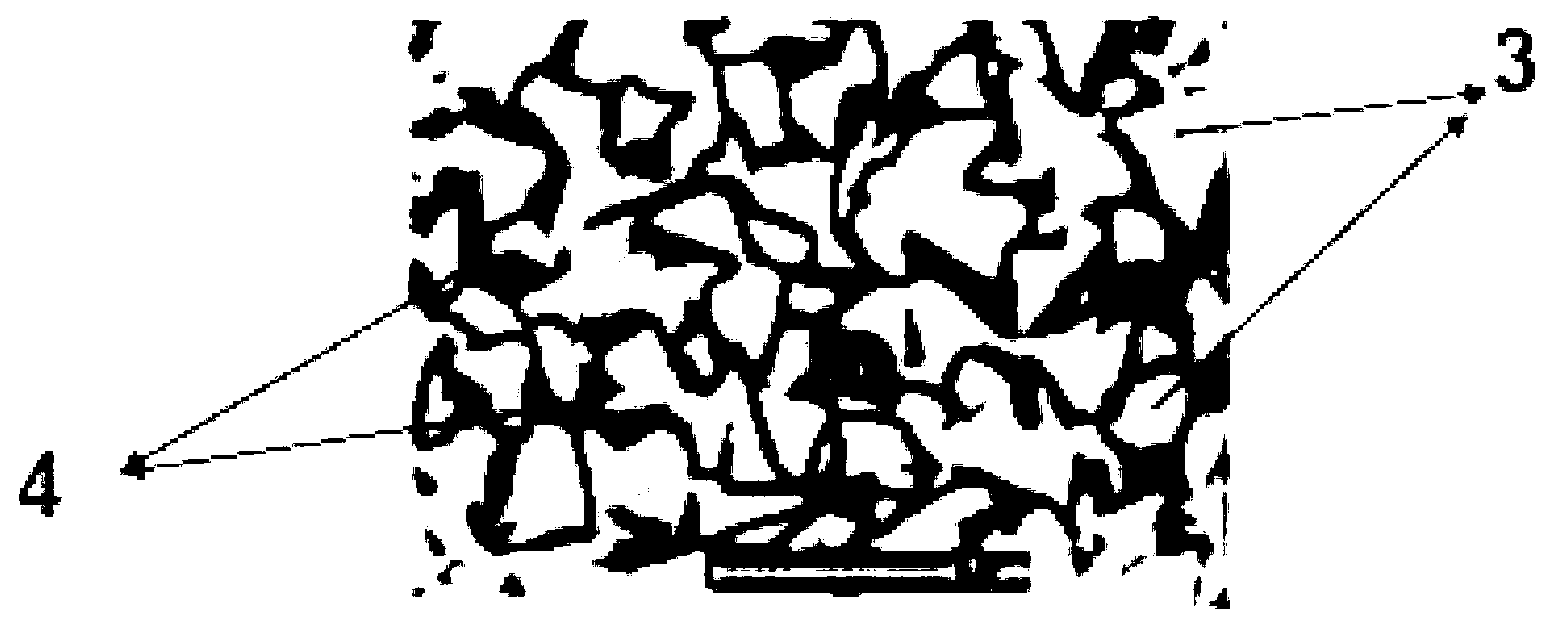

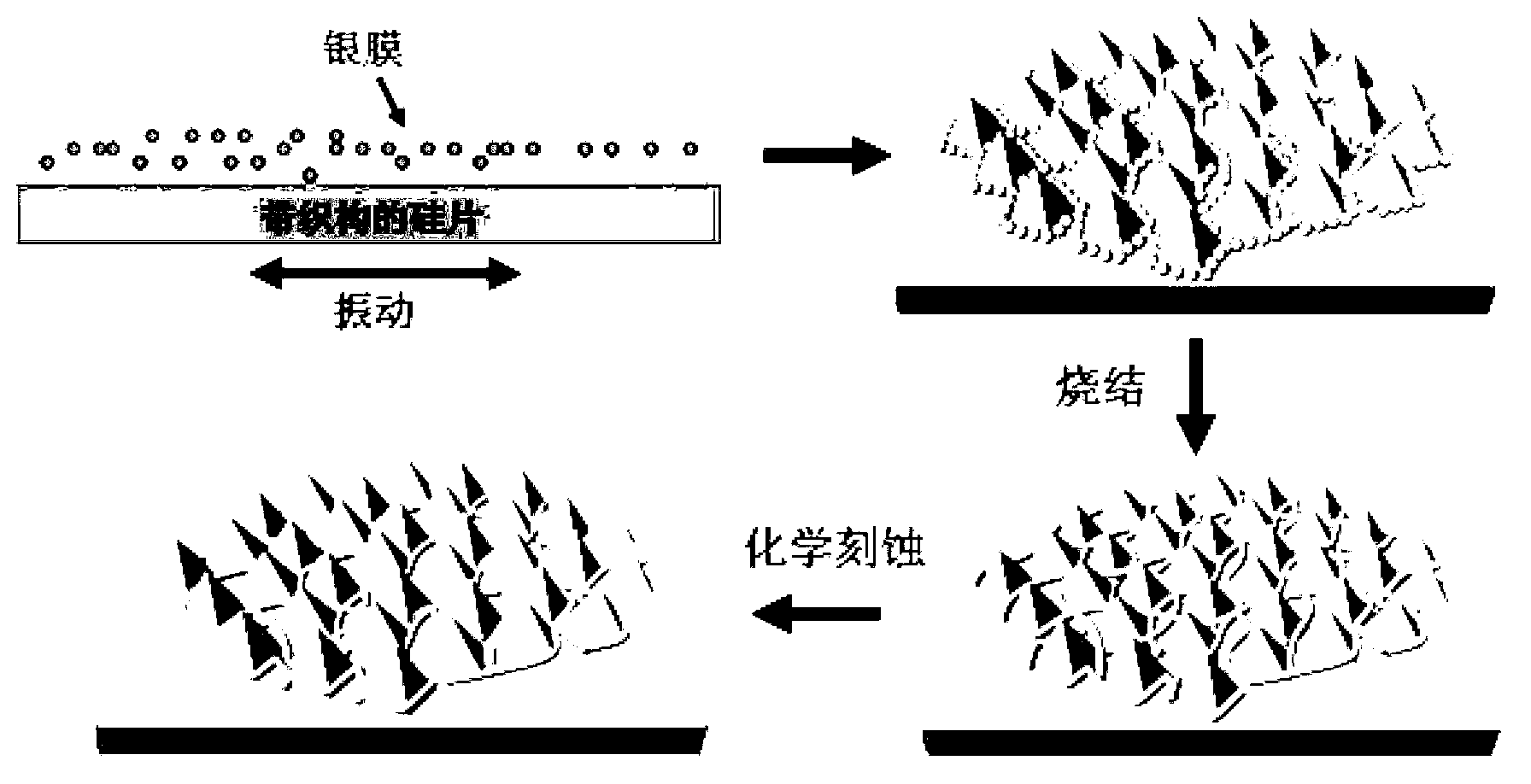

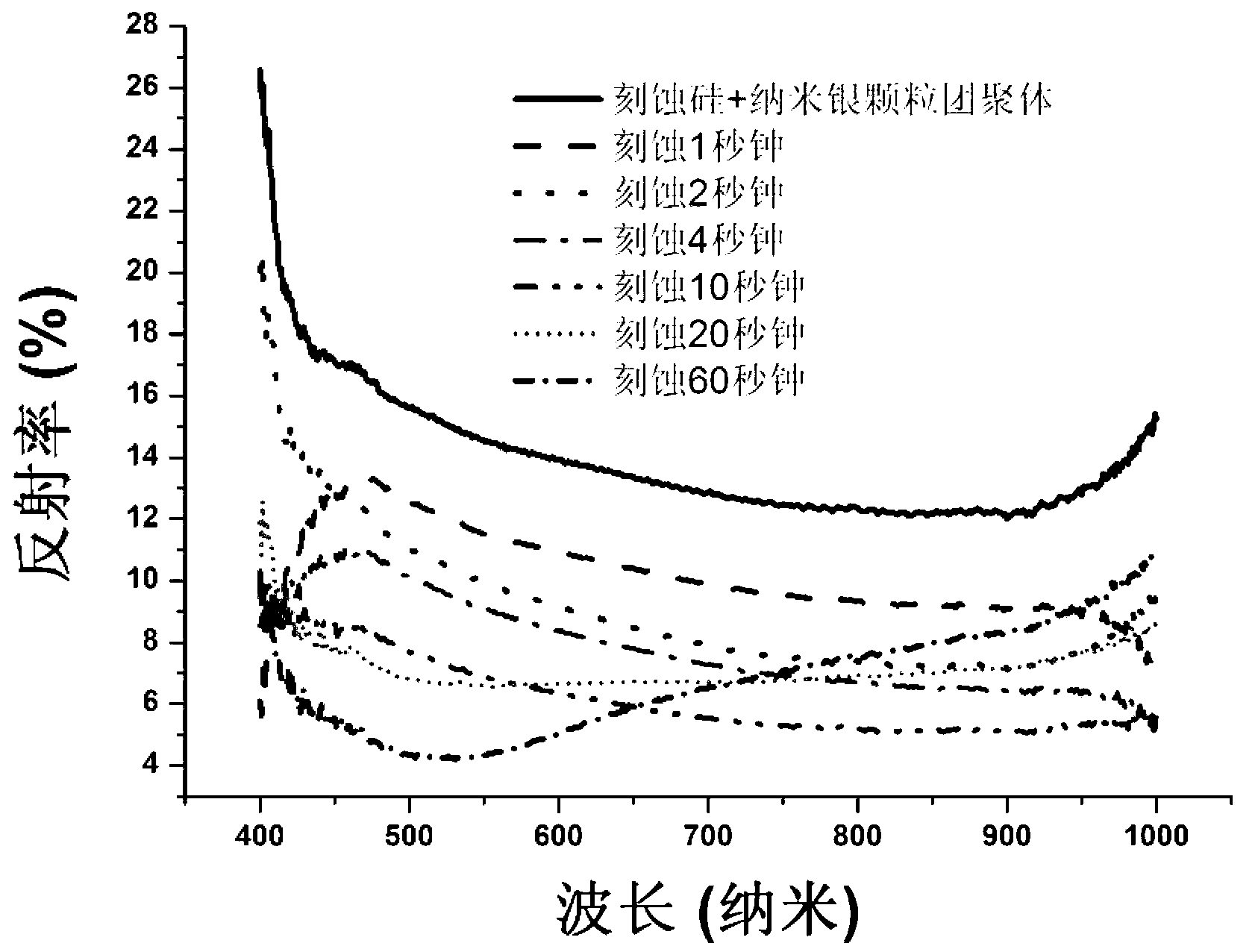

[0057] Such as image 3 The present invention discloses a method for preparing a nano-transparent buried gate electrode of a crystalline silicon solar cell, which includes four main steps: the first is the synthesis of silver ink solution, and the second is the agglomeration of nano-silver particles on the silicon surface with a pyramid texture The third is the sintering and annealing of metal nano-silver particle agglomerates to form interconnected metal nanowires / rod networks, and the fourth is metal-assisted chemical etching of samples to embed metal nanowires / rod networks into silicon wafers to form nano-buried gate transparent electrodes.

[0058] 1. Preparation of silver ink solution

[0059] Metallic silver nanoparticles used in electrodes can be synthesized by wet chemical methods. The invention adopts a simpler synthesis method, that is, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com