Colorful filter and its production method, liquid crystal display and its production method

A color filter and extinction layer technology, applied in optics, optical components, nonlinear optics, etc., can solve the problems of high reflectivity, low reflectivity optical performance, low reflectivity of color filters, etc. performance, the effect of reducing the reflectance of light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

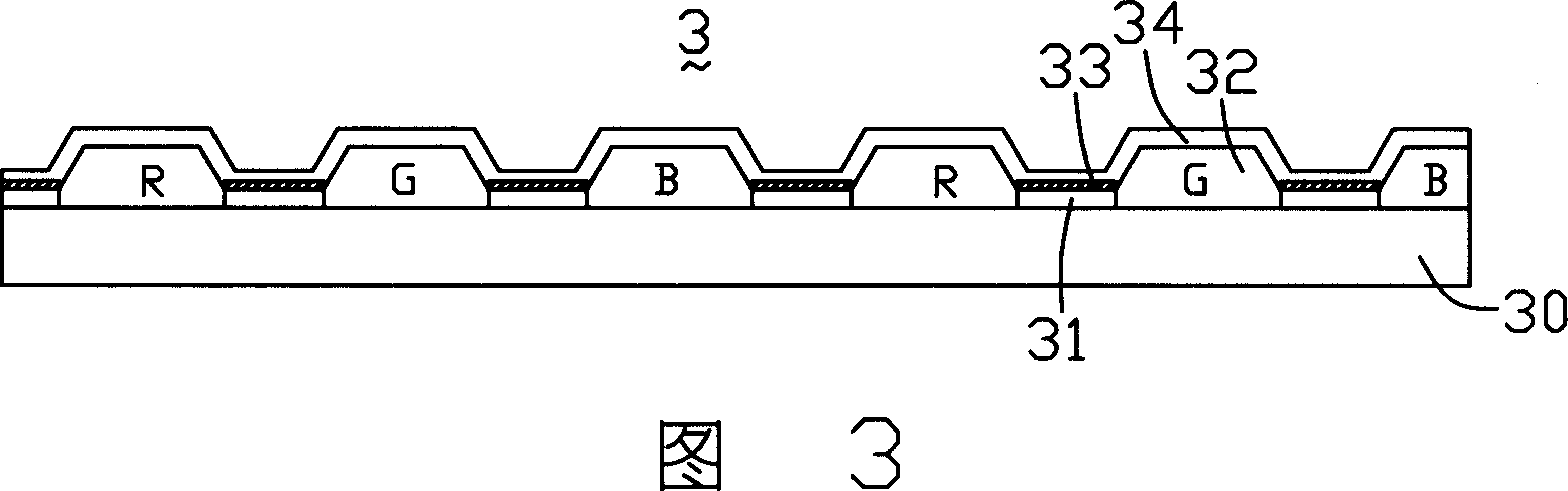

[0027] Please refer to FIG. 3 , which is a schematic diagram of a color filter disclosed in a preferred embodiment of the present invention. The color filter 3 includes: a base layer 30, a black matrix 31 arranged on the base layer 30, a colored layer 32 arranged at the interval between the black matrices 31, a matting layer 33 arranged on the surface of the black matrix 31 And a transparent conductive layer 34 disposed on the surface of the colored layer 32 and the matting layer 33 .

[0028] The base layer 30 is a transparent glass substrate, and the transparent glass substrate serves as a carrier for other components of the color filter 3 .

[0029] The black matrix 31 is formed on the surface of the base layer 30 and is regularly arranged in a grid pattern. It uses chromium and its metal compounds as materials, such as sputtering chromium (Cr), a mixture of chromium and chromium oxide (CrOx / Cr) or nickel ( Ni), forming a black matrix through a photoresist photolithography...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com