Printable flexible ammonia gas sensor and making method thereof

A kind of ammonia sensor, flexible technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of difficult to ensure product yield and life, increase the difficulty and cost of preparation, not suitable for large-scale industrial production, etc., to achieve good stability , no preparation area requirements, and the effect of improving the efficiency of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of described printable flexible ammonia sensor comprises the steps:

[0034] 1) The flexible substrate 1 is ultrasonically cleaned with cleaning solution, acetone and isopropanol in sequence, and the ultrasonic cleaning time is 10-20 minutes.

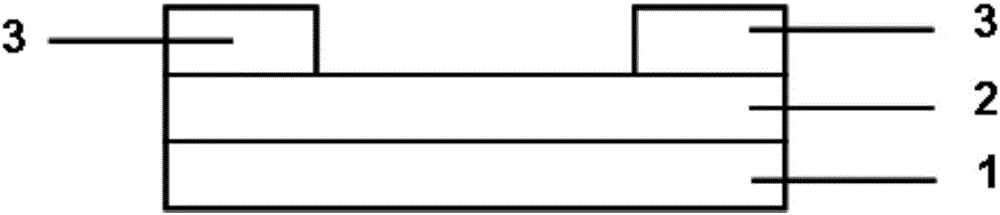

[0035] 2) Depositing a layer of the ammonia sensitive layer 2 on the surface of the flexible substrate 1, and then annealing at a low temperature; the ammonia sensitive layer 2 is prepared by scraping, spin coating, spray coating or dipping-pulling.

[0036] 3) Prepare an interdigitated electrode 3 based on conductive silver ink on the upper surface of the ammonia sensitive layer 2, and then anneal at a low temperature, the annealing temperature is 50-150°C, and the annealing time is 5-100min; the interdigitated electrode 3 Prepared by inkjet printing, dispensing or screen printing.

Embodiment 1

[0038] Firstly, the transparent flexible substrate 1 of polyethylene terephthalate is cleaned in advance, and the polyethylene terephthalate film is sequentially immersed in the cleaning solution, acetone and isopropanol, and ultrasonicated for 15 minutes each time. After ultrasonication, the flexible substrate 1 is taken out and blown dry by a nitrogen gun for use. Configure poly(3,4-ethylenedioxythiophene): a composite solution of polystyrene sulfonate and silver nanowires, the configuration process is carried out in aqueous solution, and control the silver nanowires and poly(3,4-ethylenedioxythiophene) Thiophene): the composite weight ratio of polystyrene sulfonate is 50%. A uniform thin film was deposited on the transparent flexible substrate 1 by scraping the prepared composite solution, the thickness of the thin film was controlled at 100-120 nm, and then annealed at 120° C. for 20 minutes to obtain the ammonia sensitive layer 2 . After the film is fully dried, a conduc...

Embodiment 2

[0040] Firstly, the transparent flexible substrate 1 of polyimide is cleaned in advance, and the polyimide substrate is sequentially immersed in cleaning solution, acetone and isopropanol, and ultrasonicated for 10 min each time. After ultrasonication, the flexible substrate 1 is taken out and blown dry by a nitrogen gun for use. The composite solution of the polyaniline and the gold nanowire is configured, and the configuration process is carried out in a mixed solution of ethanol and isopropanol, and the composite weight ratio of the gold nanowire and the polyaniline is controlled to be 100%. A uniform thin film was deposited on the transparent flexible substrate 1 by spin coating from the prepared composite solution, the thickness of the thin film was controlled at 100-120 nm, and then annealed at 150° C. for 10 min to obtain the ammonia sensitive layer 2 . After the film is fully dried, a conductive ink electrode based on silver nanowires is prepared on it by screen printi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com