Extraction method of taxol from branches and leaves of artificially cultivated yew

A technique for artificial cultivation of branches and leaves of Taxus chinensis, which is applied in the field of biochemical product preparation, can solve the problems of difficult separation, pollution, high toxicity of the eluent, etc., and achieves the effects of low cost, simple process and protection of plant resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

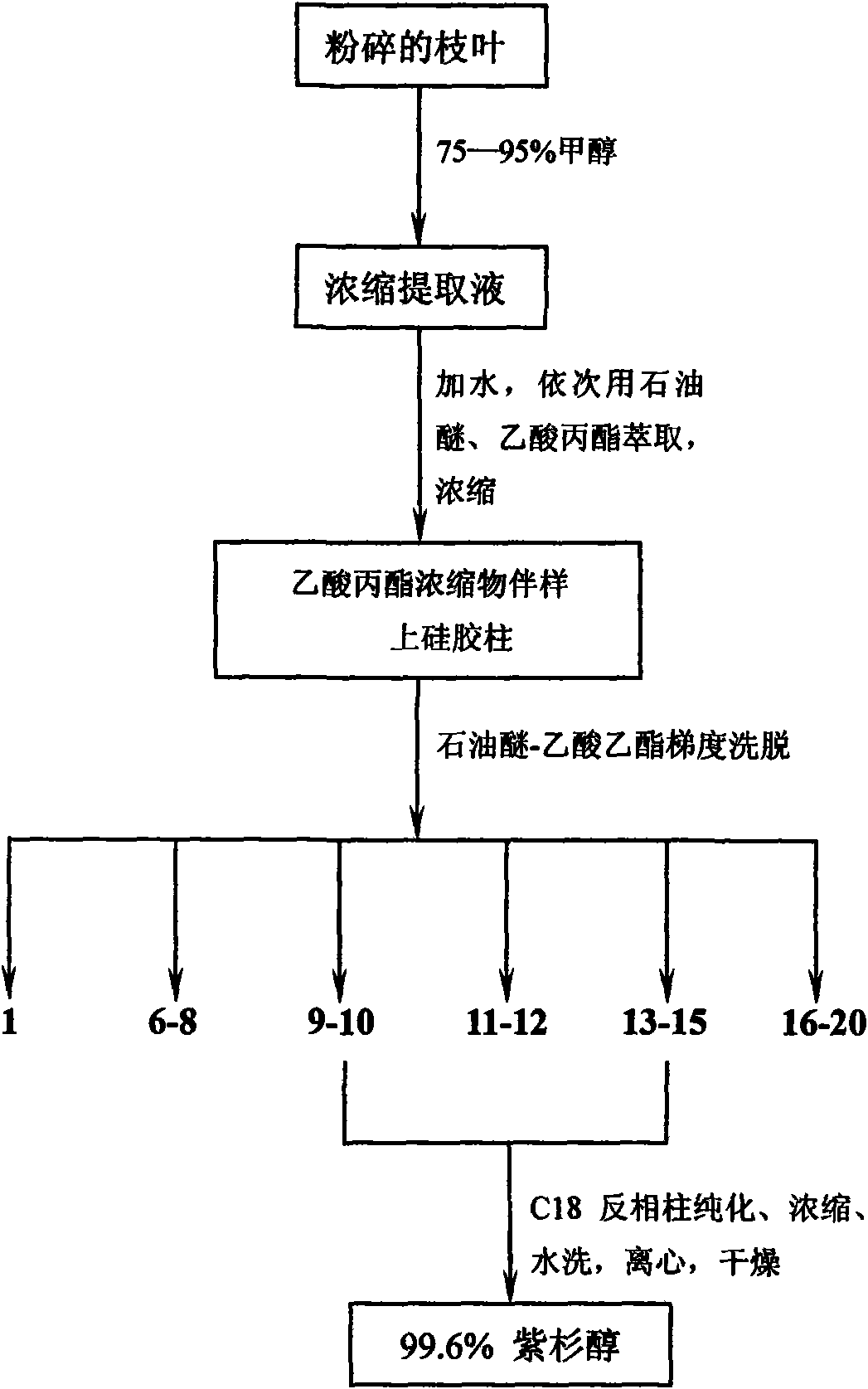

[0047] Such as figure 1 Shown, the method for extracting paclitaxel from the artificially cultivated yew branches and leaves is:

[0048] (1) Take 1 kg of dry branches and leaves of Taxus chinensis artificially cultivated, crush them with a crusher, add 3 L of 90% methanol to a 5 L round bottom flask, stir well, soak three times at 40-50 ° C, each time 4-6 Hour. Stir 3 to 6 times during the standing process. After soaking, filter to remove waste residue, and concentrate the filtrate to a light green viscous liquid with a volume of about 50ml. Add 2L of petroleum ether to the solution, mix well, add 2L of water, stir for 30 minutes, and let it stand for about 25 minutes to form a light green clear liquid in the upper layer and a dark green gelatinous liquid in the lower layer. Soluble pigments and other impurities. Add 2 L of propyl acetate to the separated lower aqueous phase, stir for 30 min, let stand for about 25 min, extract continuously for 3 times, and combine the thr...

Embodiment 2

[0056] (1) Get 100kg of fresh branches and leaves of the 3-year-old Taxus chinensis cultivated artificially, place 2m after pulverizing with a crusher 3 Then add 550L of 90% methanol, stir evenly, and soak with intermittent stirring at 40-50°C for 4 hours. After soaking, release the solution in the extraction tank, and then soak 3 times in the same way. The released methanol solutions were combined and concentrated in a concentration tank to a volume of about 25L. In the extraction tank, add about 250L of petroleum ether to the solution, mix well, add 250L of water and stir for 1 hour, let it stand for about 30min to form two layers, and separate the lower layer. Add about 250L propyl acetate to the lower layer solution, mix evenly, stir for 1 hour, and let stand for about 30min to form two layers.

[0057] (2) The propyl acetate extract of the lower layer was released, evaporated to dryness under reduced pressure, and 1032 grams of brown powder was formed, and the paclitaxe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com