Method for preparing coarse aggregates from coral reefs and concrete

A coral reef and concrete technology, which is applied in the field of preparing coarse aggregate and concrete by using coral reef, can solve the problems of insufficient concrete strength, unstable work performance, early setting of seawater and sea sand concrete, etc., to protect mines and forestry resources, The effect of promoting ecological environment protection and huge social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

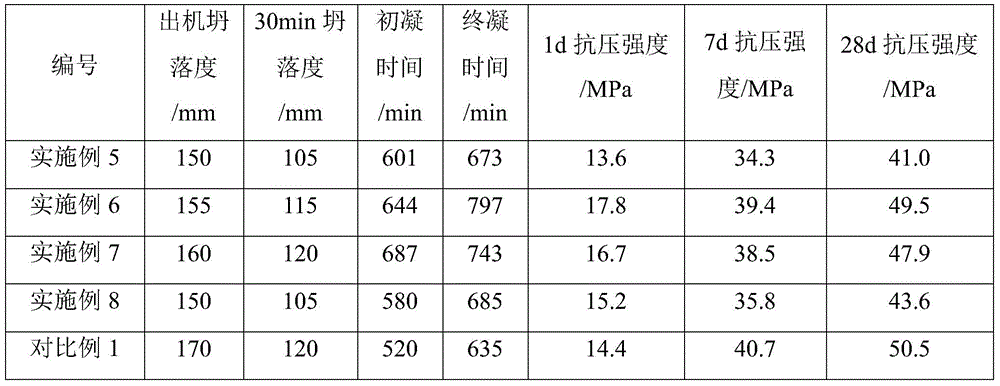

Examples

Embodiment 1

[0034] The present embodiment provides a kind of method utilizing coral reef to prepare coarse aggregate, comprising the following steps: (1) washing coral reef with seawater, then immersing the washed coral reef with 0.4mol / L hydrochloric acid for 8h, and then washing with seawater Remove residual hydrochloric acid on the surface of the coral reef; (2) pass the coral reef soaked in hydrochloric acid through a 5mm square hole sieve to obtain a sieve residue; (3) soak the sieve residue with 5% water glass solution for 10 hours Take it out and get coarse aggregate after drying in the sun.

Embodiment 2

[0036] The present embodiment provides a kind of method utilizing coral reef to prepare coarse aggregate, comprising the following steps: (1) washing coral reef with seawater, then immersing the washed coral reef with 0.8mol / L hydrochloric acid for 4h, and then cleaning with seawater Remove residual hydrochloric acid on the surface of the coral reef; (2) pass the coral reef soaked in hydrochloric acid through a 5mm square hole sieve to obtain a sieve residue; (3) soak the sieve residue with 10% water glass solution for 15 hours Take it out and get coarse aggregate after drying in the sun.

Embodiment 3

[0038] The present embodiment provides a kind of method utilizing coral reef to prepare coarse aggregate, comprising the following steps: (1) washing coral reef with seawater, then immersing the washed coral reef with 0.6mol / L hydrochloric acid for 6h, and then cleaning with seawater Remove the residual hydrochloric acid on the surface of the coral reef; (2) pass the coral reef soaked in hydrochloric acid through a 5mm square hole sieve to obtain a sieve residue; (3) soak the sieve residue with 20% water glass solution for 12 hours Take it out and get coarse aggregate after drying in the sun.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com