Gas chromatography method for organic mixture

A gas chromatographic analysis and organic mixture technology, applied in the analysis of materials, material separation, measuring devices, etc., can solve the problems of repetitive labor, low work efficiency, labor and material resources, etc., and achieve gas chromatographic analysis. The method is simple and efficient The effect of improvement and work efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

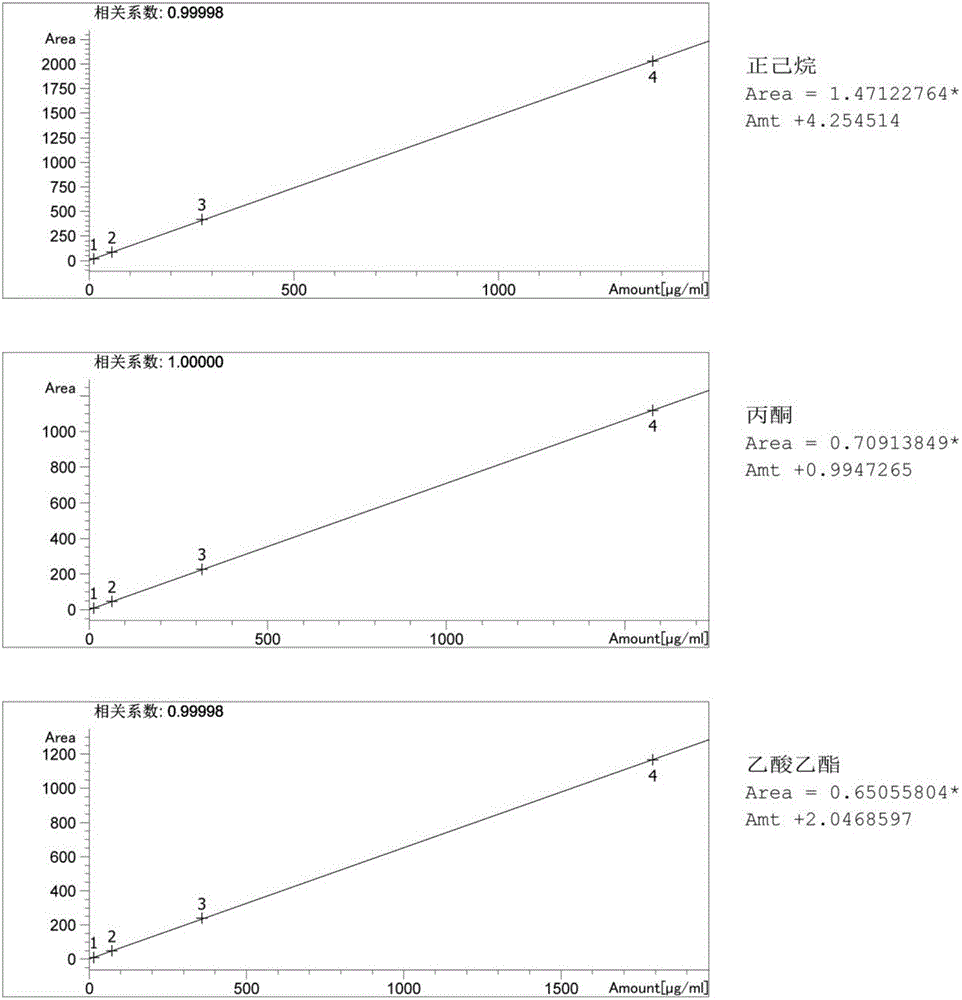

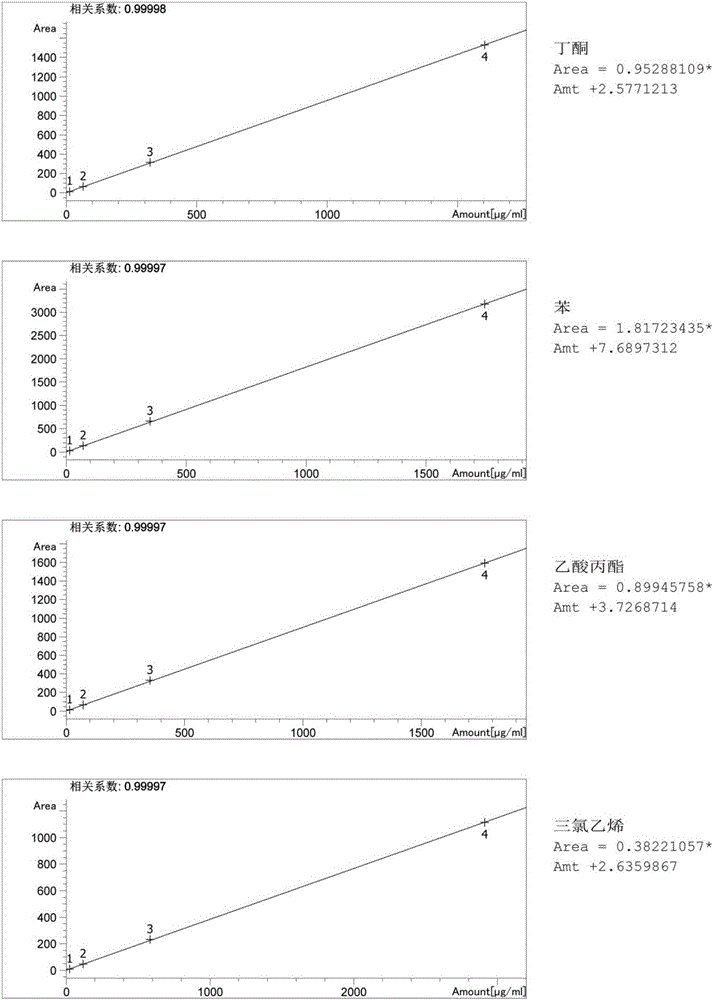

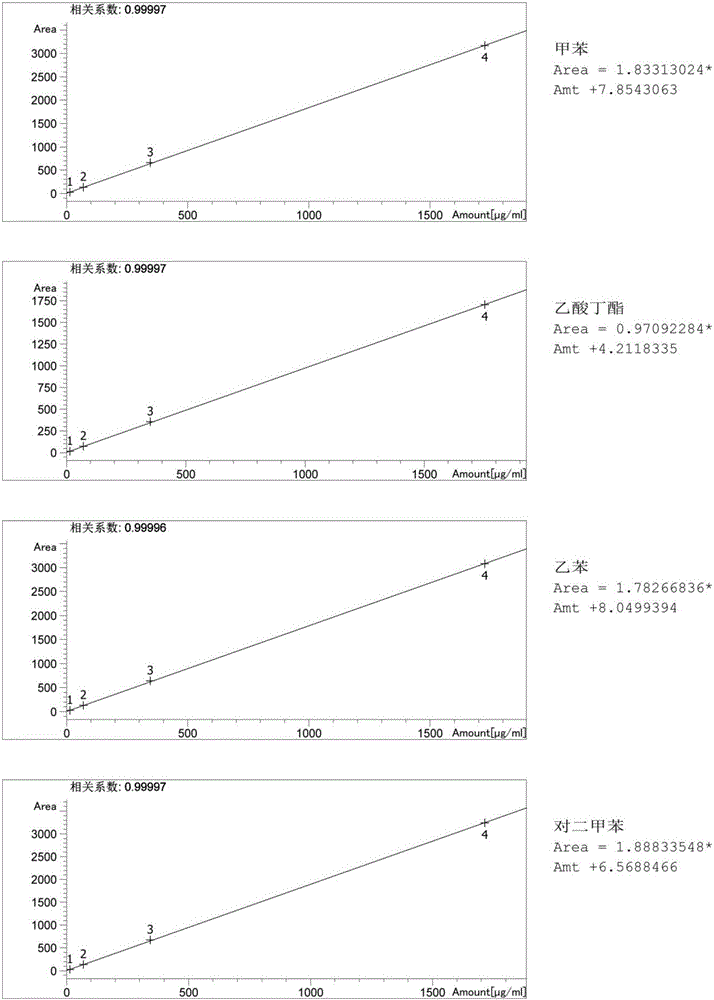

[0032] (1) Drawing of standard curve

[0033] Prepare the standard series, dilute the standard solution with carbon disulfide to form the standard series shown in Table 2.

[0034] Table 2 Standard series

[0035]

[0036] According to the standard series shown in Table 2, inject 1.0 μL respectively, and measure each standard series. The determination method is as follows: after the sample to be tested is vaporized in the vaporization chamber by the inlet, it is brought into the chromatographic column by the carrier gas at the same time, and each component in the sample is separated in the chromatographic column and then enters the detector, and the detector detects the sample that flows out of the column. Recognition and response, after the data processing system converts the signal of the detector into a chromatogram for qualitative or quantitative; the operating conditions are: the temperature of the chromatographic column is programmed, the initial temperature is 40 ° ...

Embodiment 2

[0041] Repeat test twice according to the detection method in embodiment 1, obtain data, as Figure 4 , Figure 5 shown.

Embodiment 3

[0043] According to the national standard method, the sample collected in Example 1 is analyzed, and the chromatograms of benzene, toluene, o-xylene, m-xylene, p-xylene, ethylbenzene, styrene are obtained respectively; the chromatogram of trichloroethylene; The chromatograms of alkane; the chromatograms of acetone and butanone; the chromatograms of cyclohexanone; the chromatograms of ethyl acetate, propyl acetate, and butyl acetate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com