Method for preparing salvianolic acid B and rosmarinic acid by adopting high-speed counter-current chromatography separation and purification process

A high-speed countercurrent chromatography, rosmarinic acid technology, applied in the field of natural medicine separation, can solve the problems of time-consuming and laborious, polluting the environment, irreversible adsorption, etc., and achieve the effects of good separation effect, less solvent consumption and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

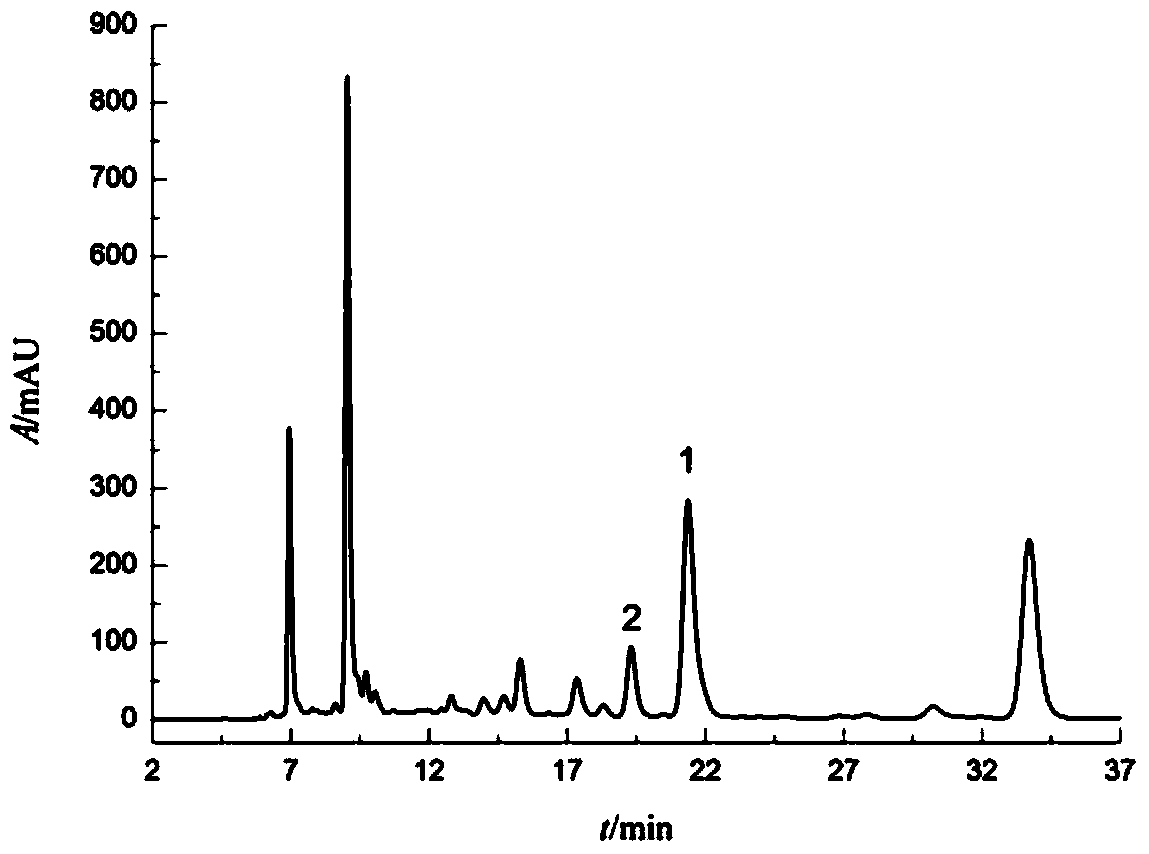

[0033] 1. Take 100g of Salvia miltiorrhiza and crush it into a coarse powder, add 1000mL of 50% ethanol by heating and reflux for extraction twice, extract for 1 hour each time, combine the extracts and filter, cool to room temperature, and depressurize the filtrate to alcohol-free with a rotary evaporator , to obtain ethanol extract 62g, its high performance liquid chromatogram is as follows figure 1 shown.

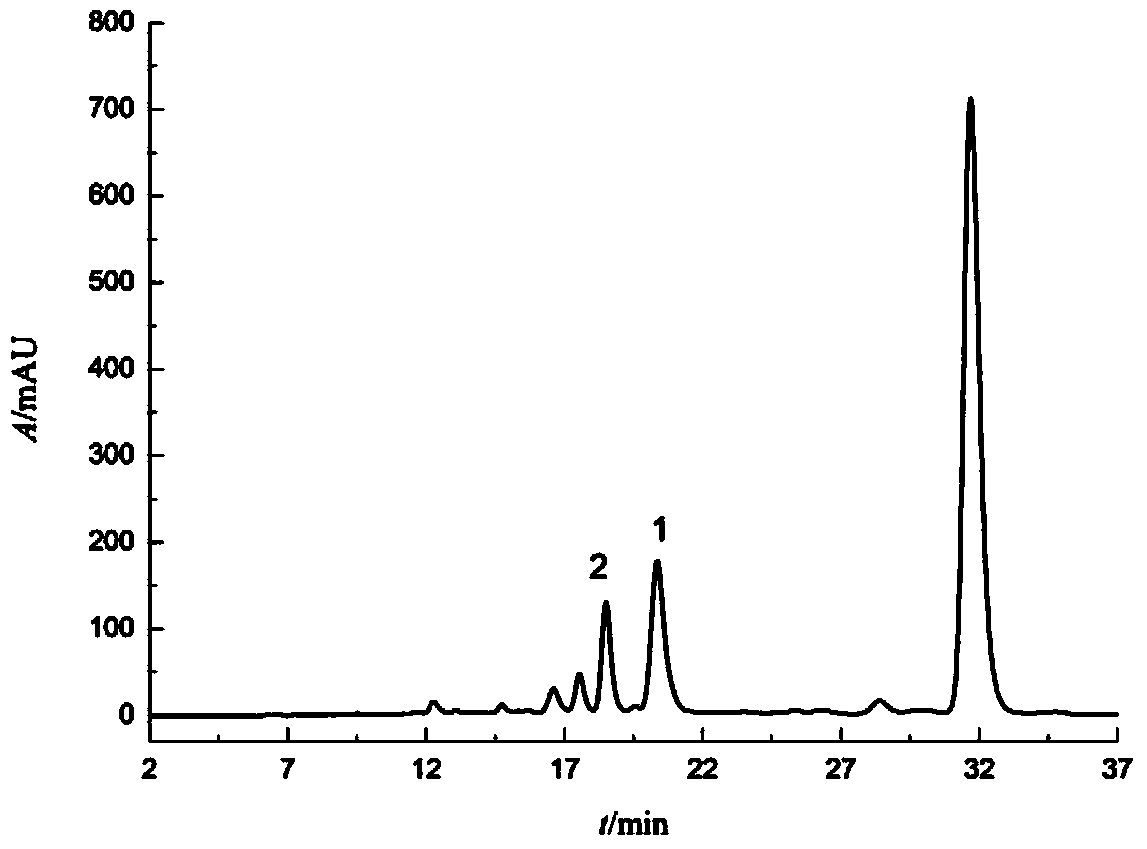

[0034] 2. After dispersing 3.6g ethanol extract with 30mL water, add it to HPD300 macroporous adsorption resin column chromatography. % ethanol → 5 times column volume 50% ethanol → 5 times column volume 60% ethanol → 5 times column volume 95% ethanol solution elution, collect the ethanol eluate containing the target product salvianolic acid B, rosmarinic acid, reduce Concentrate under pressure to no alcohol, dry to obtain the mixed crude extract of salvianolic acid B and rosmarinic acid, the HPLC figure is shown in figure 2 . (% means volume fraction)

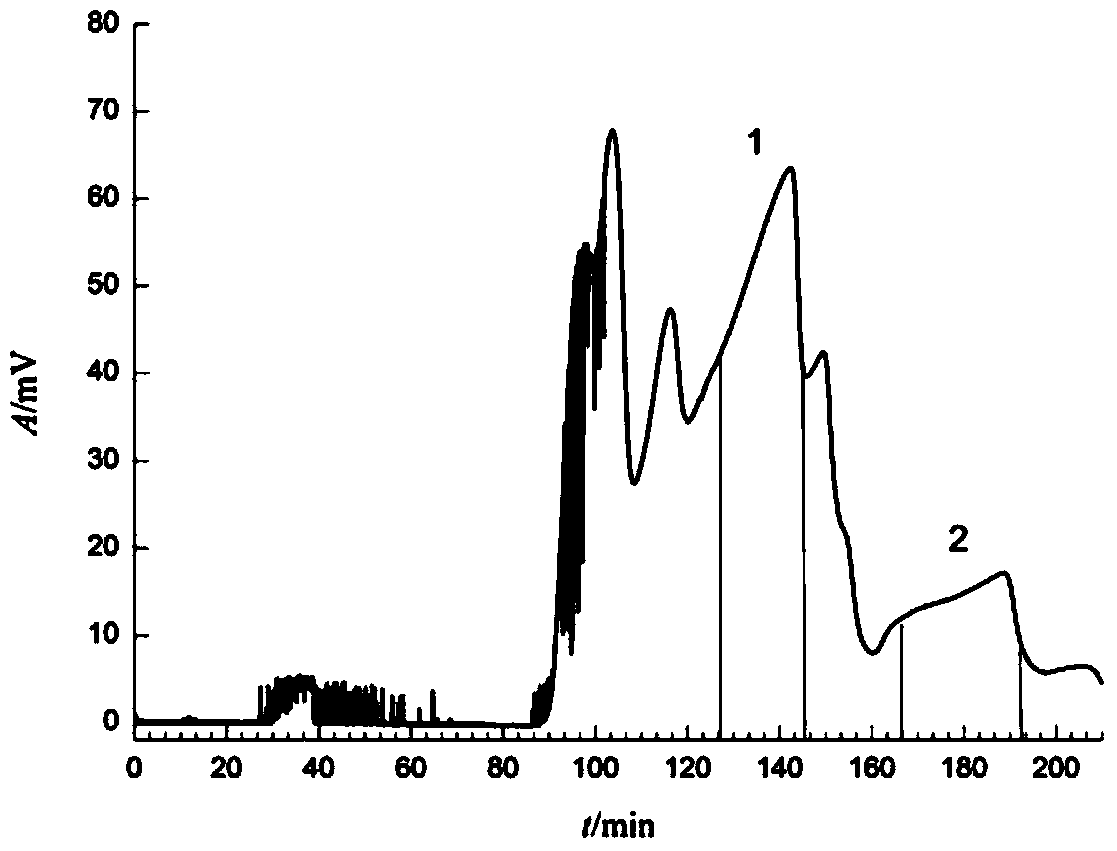

[0035] 3. U...

Embodiment 2

[0042] 1. Extraction of Salvia miltiorrhiza and separation by macroporous resin chromatography are the same as in Example 1.

[0043] 2. Use high-speed countercurrent chromatography to separate and purify the crude extract: take n-hexane, ethyl acetate, methanol, and water, mix them in a volume ratio of 3:7:1:9, mix them well and let stand, separate the upper and lower phases, and take the upper and lower phases. The phase is the stationary phase, and the lower phase is the mobile phase. Fill the stationary phase with the multi-layer coil separation column of the high-speed countercurrent chromatograph, turn on the high-speed countercurrent chromatograph, and adjust the speed to 800r min -1 , inject mobile phase, mobile phase flow rate 1.8mL min -1 , when the mobile phase obviously flows out, take 172mg of the mixed crude extract of salvianolic acid B and rosmarinic acid, dissolve it in 10mL of the mixture of upper phase and lower phase with a volume ratio of 1:1, and inject t...

Embodiment 3

[0046] 1. Extraction of Salvia miltiorrhiza and separation by macroporous resin chromatography are the same as in Example 1.

[0047] 2. Use high-speed countercurrent chromatography to separate and purify the crude extract: Take n-hexane, ethyl acetate, acetone, and water, mix them in a volume ratio of 3:7:1:9, and let stand after mixing fully. Separate the upper and lower phases, and take the upper and lower phases. The phase is the stationary phase, and the lower phase is the mobile phase. Fill the stationary phase with the multi-layer coil separation column of the high-speed countercurrent chromatograph, turn on the high-speed countercurrent chromatograph, and adjust the speed to 800r min -1 , inject mobile phase, mobile phase flow rate 1.8mL min -1 , when the mobile phase obviously flows out, take 156mg of the mixed crude extract of salvianolic acid B and rosmarinic acid, dissolve it in 10mL of the upper phase and lower phase mixed solution with a volume ratio of 1:1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com