Production method of glucose injection

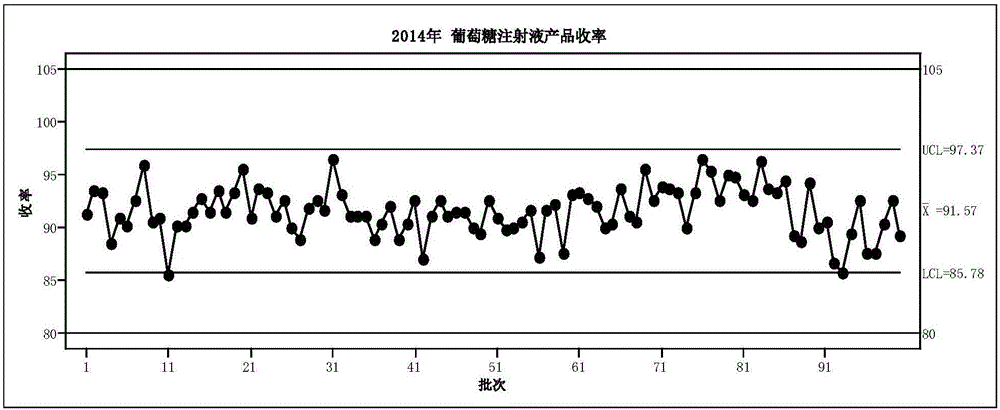

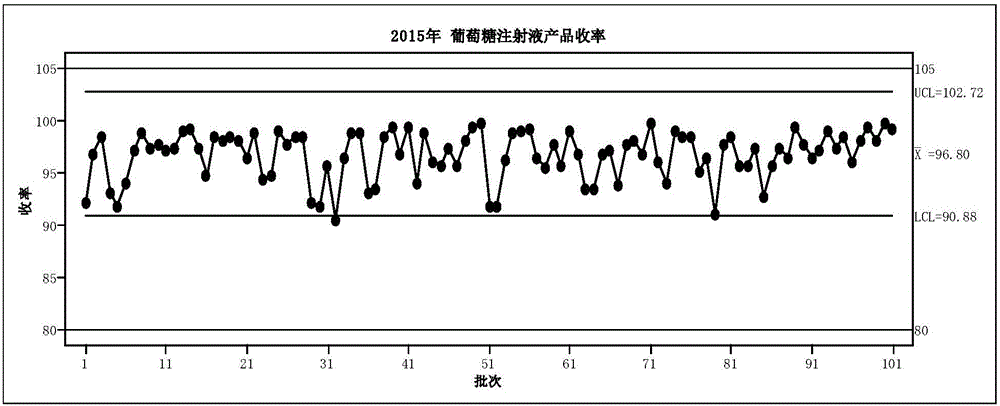

A technology of glucose injection and production method, which is applied in the production field of glucose injection, can solve the problems of increasing manpower and material costs, and achieve the effect of reducing visible foreign matter and stabilizing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

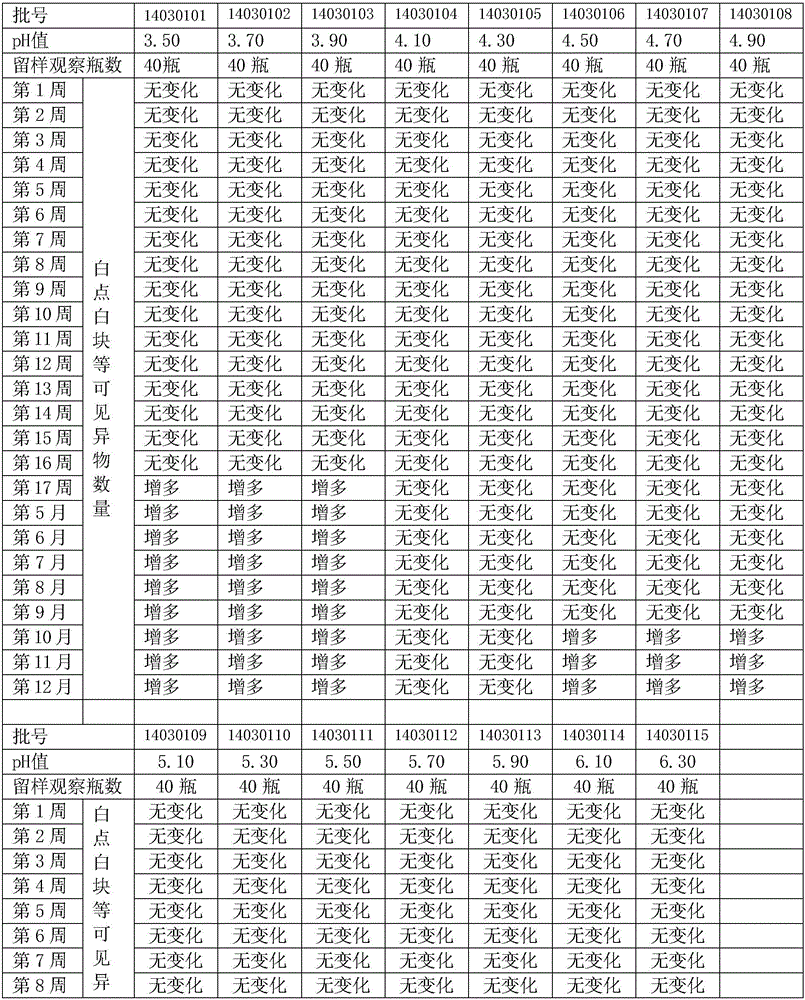

Examples

Embodiment 1

[0028] A kind of production method of glucose injection, comprises the steps:

[0029] 1) Weighing: prepare raw and auxiliary materials;

[0030] 2) Concentrated preparation: place the weighed glucose in a concentrated preparation tank with water for injection to prepare a 60% (w / w) concentrated solution, add medical hydrochloric acid and 0.05% (w / v) charcoal for needles and mix Control the pH at 3.8, heat, boil for 15-30 minutes, pressurize, decarbonize until clear, and transfer to the diluted tank;

[0031] 3) Dilute preparation: add water for injection to the full amount in the dilute preparation tank, circulate until clear, adjust the pH value to 4.3, measure the glucose content to be 98.0-104.0% of the marked amount, and filter after passing the test; take samples to check the properties and content of the liquid , pH value, after passing the test, filter through a 0.45um pore size pleated filter element connected in series with a 0.45um pore size pleated filter element,...

Embodiment 2

[0038]A kind of production method of glucose injection, comprises the steps:

[0039] 1) Weighing: prepare raw and auxiliary materials;

[0040] 2) Concentrated preparation: place the weighed glucose in a concentrated preparation tank with water for injection to prepare a 40% (w / w) concentrated solution, add medicinal hydrochloric acid and 0.05% (w / v) charcoal for needles and mix Control the pH at 4.0, heat, boil for 15-30 minutes, pressurize, decarbonize until clear, and transfer to the dilute tank;

[0041] 3) Dilute preparation: add water for injection to the full amount in the dilute preparation tank, circulate until clear, adjust the pH value to 4.1, measure the glucose content to 98.0-104.0% of the marked amount, and filter after passing the test; take samples to check the properties and content of the liquid , pH value, after passing the test, filter through a 0.45um pore size pleated filter element connected in series with a 0.45um pore size pleated filter element, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com