Extraction device

A technology of extraction device and lifting device, which is applied in solvent extraction, solid solvent extraction, separation methods, etc., can solve the problems of limited production scale and production capacity, time-consuming, time-consuming and labor-intensive feeding, etc. The effect of liquid turbidity and improvement of extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

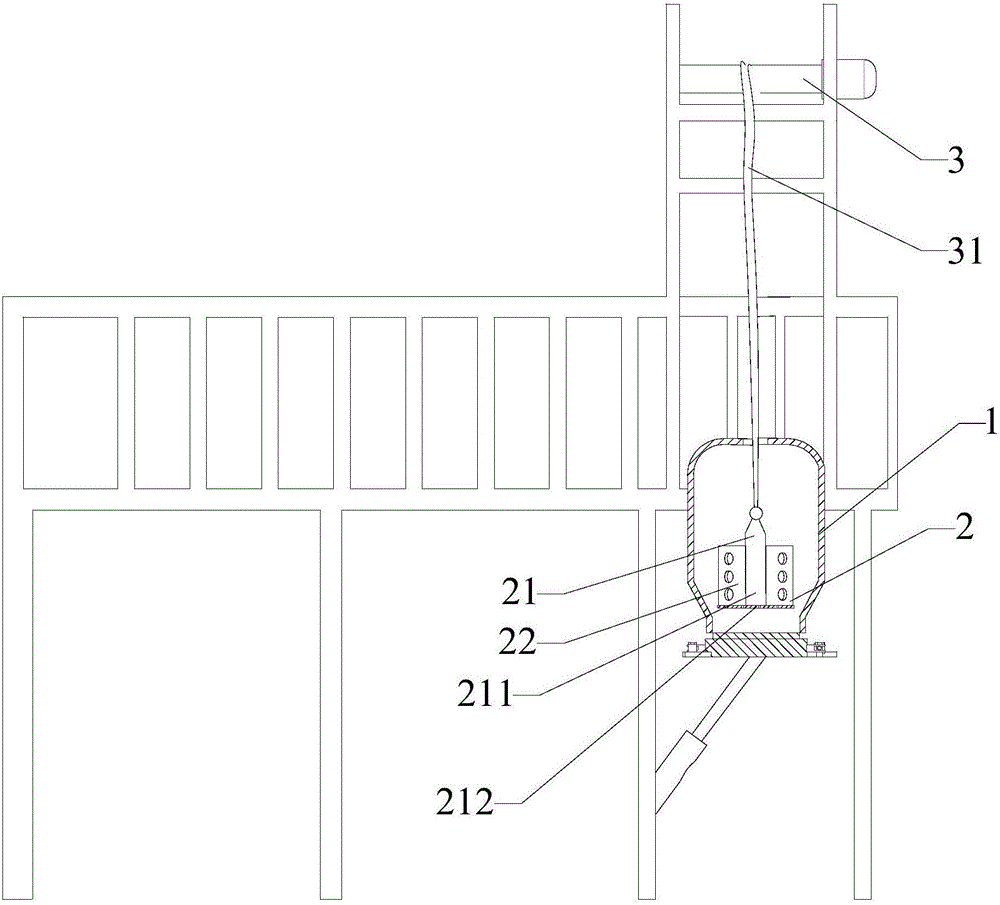

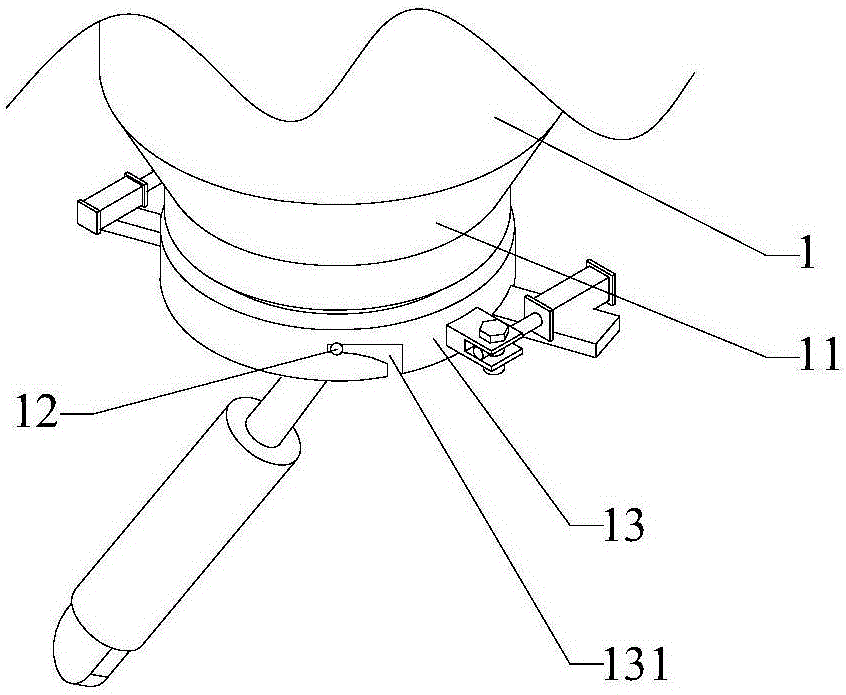

[0034] An extraction device, comprising a tank body, a filter basket and a lifting device;

[0035] The tank body is suspended on a support, the bottom of the tank body is provided with a filter basket inlet and outlet, and a sealing cover is provided on the filter basket inlet and outlet; A retractable rope is connected to the filter basket through the top of the tank from the outside of the tank.

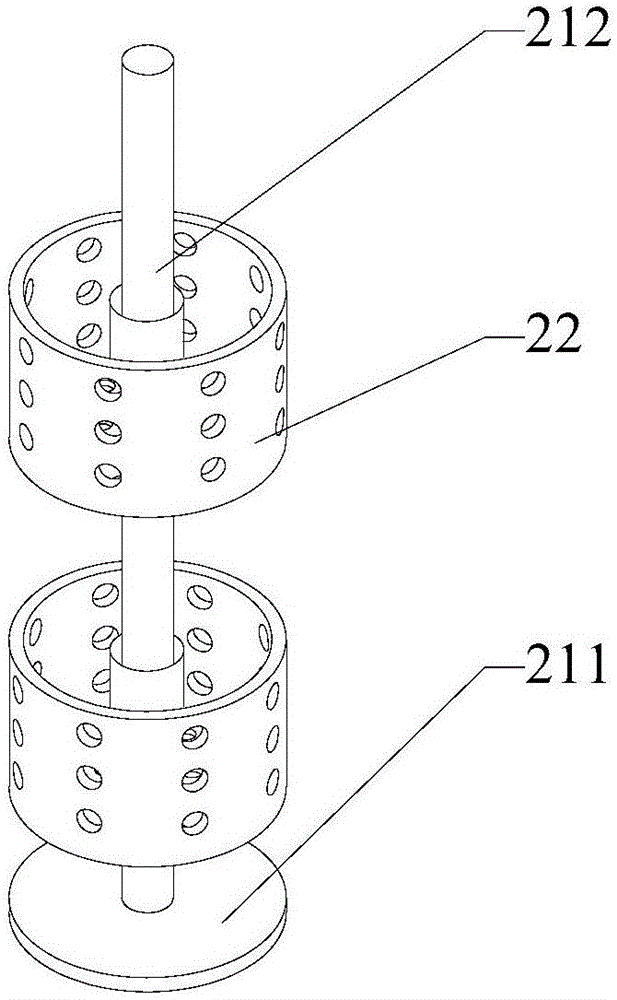

[0036] The filter basket includes a lifting device and a filter basket body. The lifting device includes a supporting circular plate and a lifting cylinder vertically connected to the center of the circular plate. The center of the filter basket body is a cylindrical cavity that penetrates up and down. The lifting device The cross-section of the cylinder is smaller than the cross-section of the cylindrical cavity, and the filter basket passes through the lifting cylinder and is arranged on the support circular plate. The number of the filter blue body is 3.

[0037] The lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com