Treatment method of condensed wastewater generated in para-ester production process

A treatment method and technology in the production process, applied in the field of condensation wastewater treatment, can solve the problems of increasing the difficulty of treatment, loss of excessive condensing agent, increase of COD in wastewater, etc., achieve low cost, realize recycling, and reduce the effect of COD value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

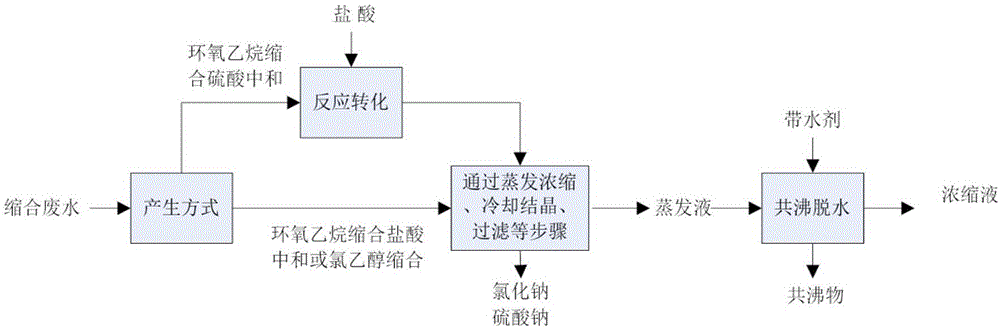

Method used

Image

Examples

Embodiment 1

[0025] In the para-ester condensation process, ethylene oxide is used to condense, neutralize with hydrochloric acid, and filter to obtain condensation waste water. Get 400ml condensation waste water (COD value is 35910ppm) and add in 500ml flask, stir and heat up, by evaporation concentration (adopt MVR evaporator to carry out evaporation concentration), cooling crystallization, the steps such as filtration, obtain sodium sulfate 71.84g, sodium chloride 42.34g, Evaporated liquid 332.8ml. The evaporative liquid was collected and put into a 500ml flask, toluene was added as a water-carrying agent, heated, and azeotropically distilled to obtain 42.46 g of a concentrated solution containing chloroethanol with a chloroethanol content of 39.5%.

[0026] The mixed solution of water-carrying agent and water obtained in the azeotropic distillation step was allowed to stand for stratification, and the obtained water was collected, and the COD value was measured to be 237 ppm.

Embodiment 2

[0028] The para-ester condensation process adopts ethylene oxide to condense, neutralize with sulfuric acid, and filter to obtain condensation waste water. 400ml of condensation waste water (COD value 38218ppm) was taken into a 500ml flask, 35g of 32% hydrochloric acid was added, the temperature was raised to 60°C with stirring, and the reaction was carried out for 5 hours. Then continue to heat up, and obtain 39.74 g of sodium chloride, 97.06 g of sodium sulfate, and 336.4 ml of evaporative liquid through the steps of evaporative concentration (using MVR evaporator for evaporative concentration), cooling crystallization, and filtration. The evaporative liquid was collected and put into a 500ml flask, benzene was added as a water-carrying agent, heated, and azeotropically distilled to obtain 35.63 g of a concentrated solution containing chloroethanol with a chloroethanol content of 46.7%.

[0029] The mixed liquid with water agent and water obtained in the azeotropic distillat...

Embodiment 3

[0031] The para-ester condensation process adopts chloroethanol to condense, and the condensation waste water is obtained by filtration. Get 400ml of condensation waste water (COD value is 36365ppm) and add it in 500ml flask, stir and heat up, through steps such as evaporation concentration (using MVR evaporator to carry out evaporation concentration), cooling crystallization, filtration, obtain sodium chloride 38.53g, sodium sulfate 63.82g, Evaporated liquid 322.5ml. The evaporative liquid was collected and put into a 500ml flask, benzene was added as a water-carrying agent, heated, and azeotropically distilled to obtain 42.75g of a concentrated solution containing chloroethanol with a chloroethanol content of 42.8%.

[0032] The mixed liquid with water agent and water obtained in the azeotropic distillation step was allowed to stand for stratification, and the obtained water was collected, and its COD value was measured to be 218 ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com