Water-based two-component matte white finish paint and preparation method thereof

A two-component, white topcoat technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of water-based two-component topcoats that cannot be recycled, viscosity rises, and cannot be sprayed efficiently. Large-scale production use, good viscosity stability, the effect of improving the usable time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

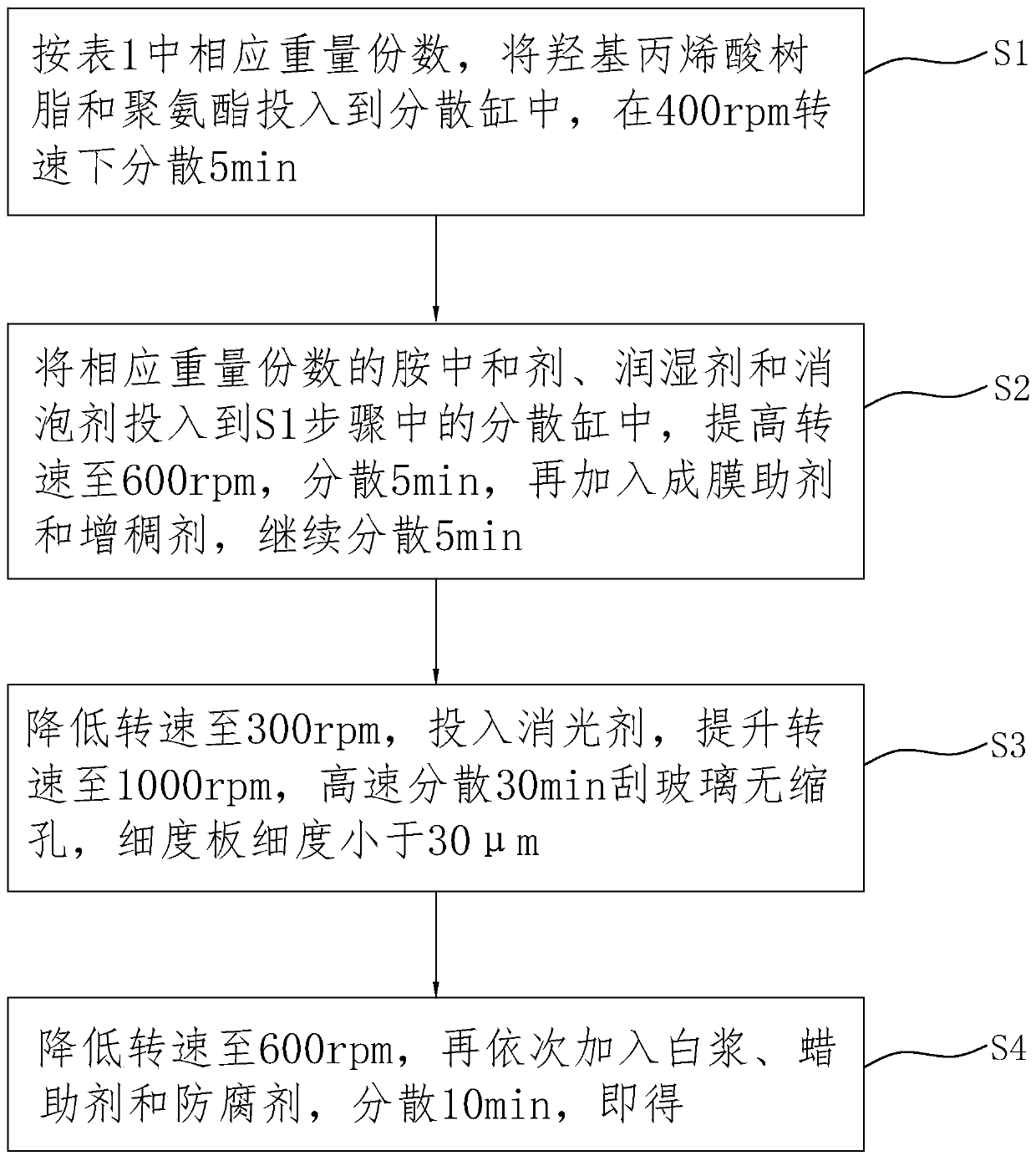

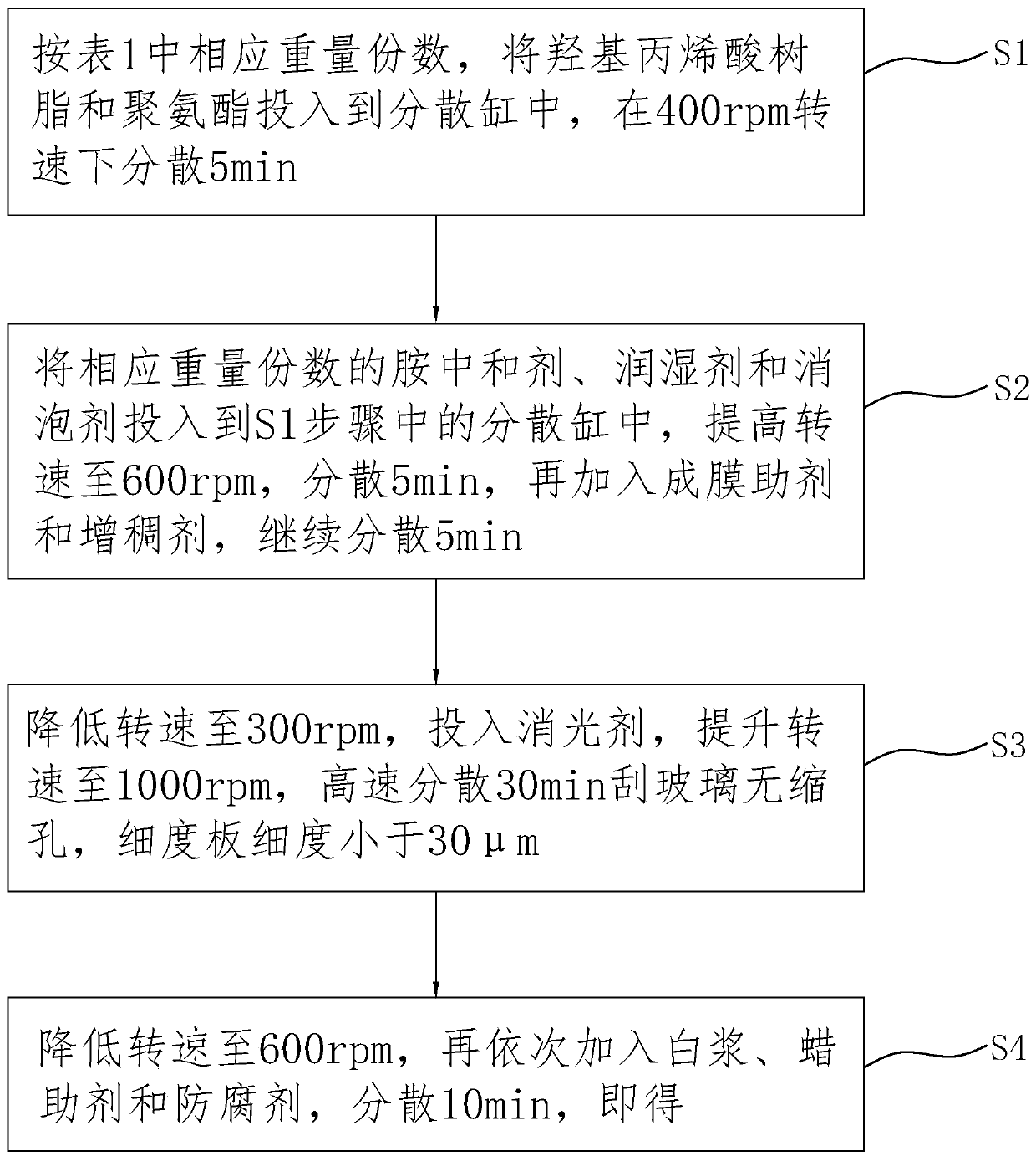

[0056] Embodiment 1: A kind of water-based two-component matte white topcoat, each component and its corresponding parts by weight are as shown in Table 1, wherein the first component is prepared through the following steps:

[0057] S1, according to the corresponding parts by weight in Table 1, put the hydroxyl acrylic resin and polyurethane into the dispersion tank, and disperse at 400rpm for 5min;

[0058] S2, put the amine neutralizer, wetting agent and defoamer of the corresponding parts by weight into the dispersion cylinder in the S1 step, increase the rotating speed to 600rpm, disperse for 5min, then add the film-forming aid and thickener, continue Disperse for 5 minutes;

[0059] S3, reduce the speed to 300rpm, put in the matting agent, increase the speed to 1000rpm, disperse at high speed for 30 minutes and scrape the glass without shrinkage cavity, and the fineness of the fineness plate is less than 30μm;

[0060] S4, reduce the rotation speed to 600rpm, then add w...

Embodiment 2-6

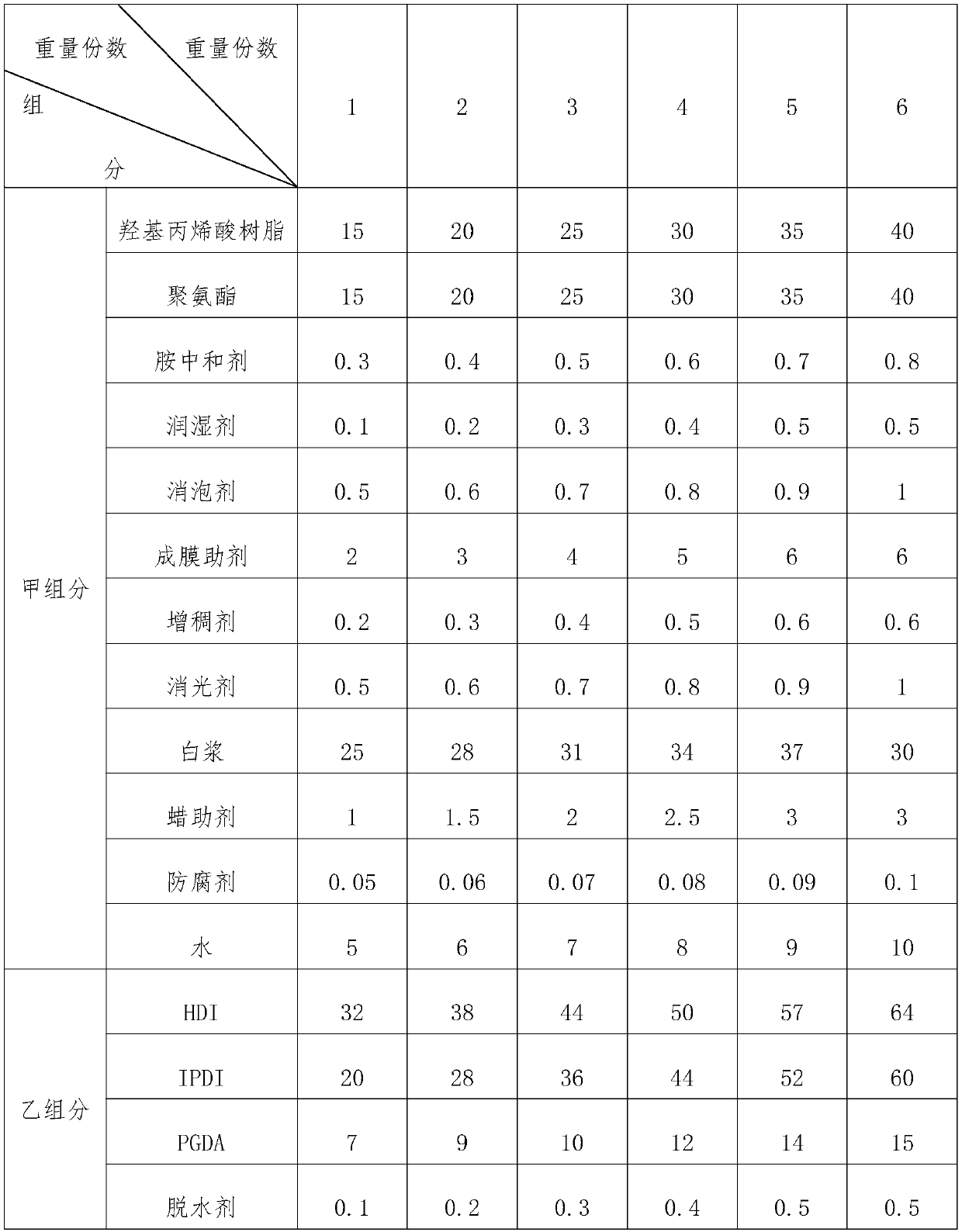

[0074] Example 2-6: A water-based two-component matte white topcoat. The difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0075] Each component and parts by weight thereof in table 1 embodiment 1-6

[0076]

Embodiment 7

[0077] Embodiment 7: A kind of water-based two-component matt white finish paint, the difference with embodiment 1 is that the hydroxyl group content of the hydroxyacrylic resin in the first component is 3.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com