Magnesia material for repairing converter lining, and preparation method and using method thereof

A converter lining and magnesia technology, which is applied in the field of refractory materials, can solve the problems of inability to repair pits or grooves, affect the rhythm of converter steelmaking, and long sintering time of repair materials, etc., so as to prolong life, improve converter operation rate, shorten The effect of maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

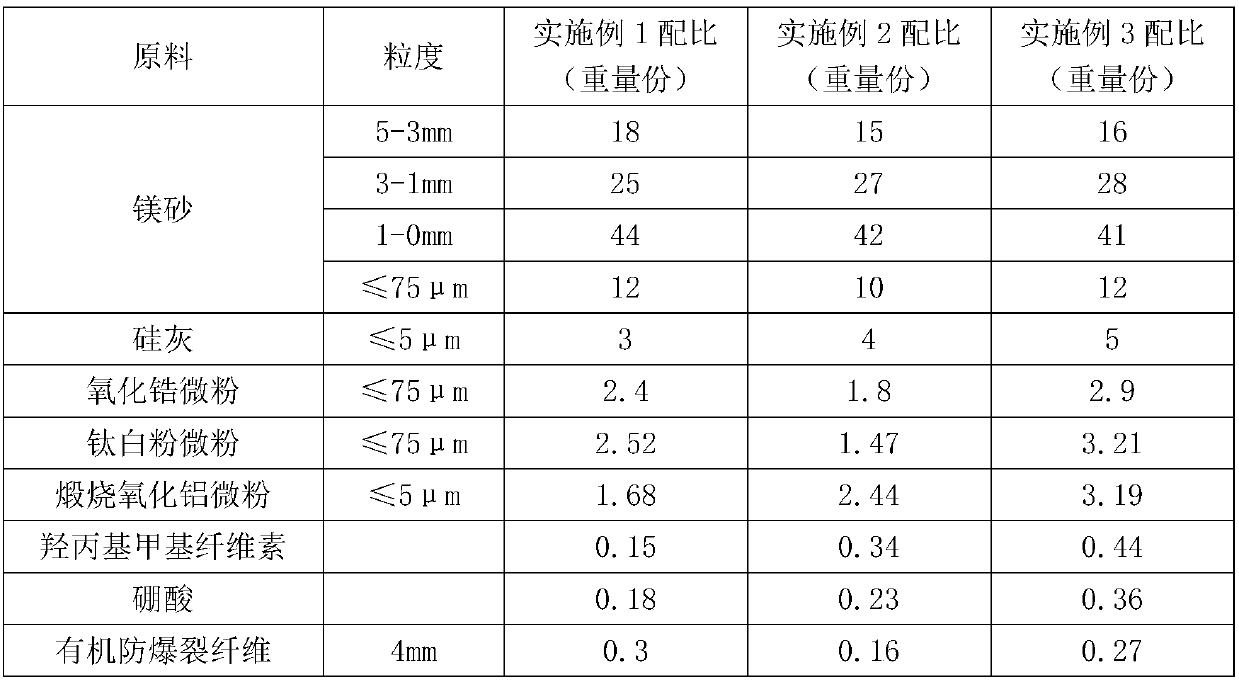

Examples

preparation example Construction

[0027] A preparation method of the magnesium material, comprising:

[0028] According to the composition ratio of the magnesia material, weigh the main raw materials, binders, additives, anti-bleeding agent, retarder and anti-cracking agent respectively; put all the raw materials that make up the magnesia material except water into the mixer Mix evenly in the medium to make a mixed dry material for later use; add water and stir the mixed dry material for 10-20 minutes before use, which is the finished product.

[0029] A method for using the magnesium material, comprising:

[0030] Put the magnesia material made by adding water and mixing the mixed dry material into the converter with a scrap steel trough; shake the converter so that the magnesia material stays in the pit to be repaired in the converter; after sintering for 10 to 20 minutes, the repair is completed. The finished converter can start smelting immediately.

[0031] Magnesium materials for repairing steelmaking ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com