Super-hydrophobic polyolefin hollow fiber membrane for oxygenated membrane and preparation method of super-hydrophobic polyolefin hollow fiber membrane

A polyolefin, super-hydrophobic technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of high production cost of oxygenation membrane, complicated operation, poor blood compatibility, etc. Capacitive, high gas transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

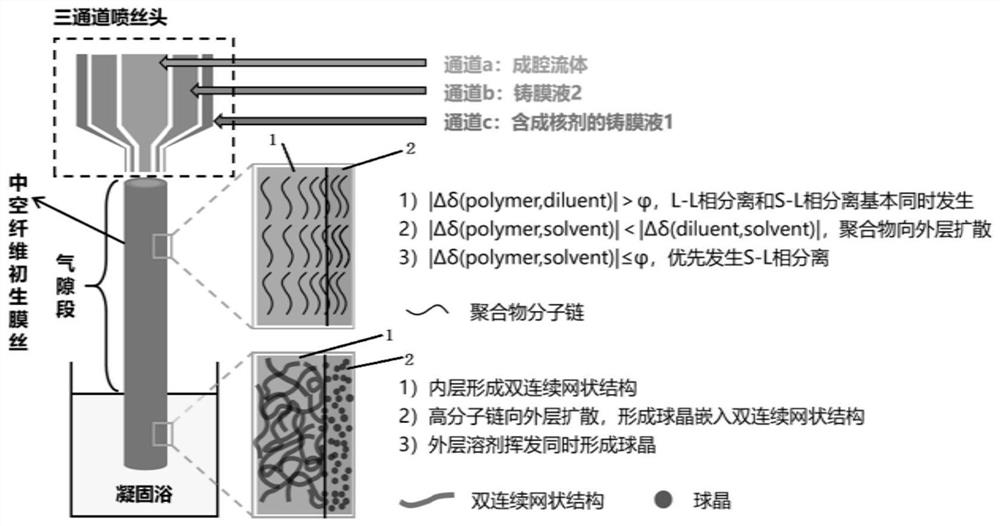

[0033] Concrete, the first aspect of the present invention provides a kind of preparation method of the superhydrophobic polyolefin hollow fiber membrane that is used for oxygenation membrane, it comprises the steps:

[0034] (1) Preparation of polyolefin casting solution 1: adding polyolefin and nucleating agent to solvent 1, stirring and dissolving, and vacuum degassing to obtain said polyolefin casting solution 1; the solubility parameters of said polyolefin and solvent 1 The absolute value of the difference |Δδ(p,s)| is less than the critical value of the membrane structure transition

[0035] (2) Preparation of polyolefin casting solution 2: adding polyolefin to solvent 2, stirring and dissolving, and degassing to obtain said polyolefin casting solution 2; the absolute value of the solubility parameter difference between said polyolefin and solvent 2 | Δδ(p,d)| is not less than the critical value of the transition of the membrane structure

[0036] (3) Quantitatively...

Embodiment 1

[0065] Embodiment 1: This example provides a kind of superhydrophobic polyolefin hollow fiber membrane that is used for oxygenation membrane, and its preparation method comprises the steps:

[0066] (1) Prepare casting solution 1: add 55wt% isotactic polypropylene, 44wt% dioctyl adipate, and 1wt% tetrabutylphosphine hexafluorophosphate into a high-temperature container, heat and stir at 190°C for 5h to obtain Homogeneous polymer solution, stand at constant temperature and vacuum defoam before use.

[0067] (2) Preparation of casting solution 2: add 35wt% isotactic polypropylene and 65wt% glycerol triacetate into a high-temperature container, heat and stir at 190°C for 4 hours to obtain a uniform polymer solution, and leave it at a constant temperature for vacuum defoaming stand-by.

[0068] (3) Use a metering pump to quantitatively feed the casting solution 1 to the outermost channel of the three-channel spinneret; use a screw extruder and a spinning metering pump to quantita...

Embodiment 2

[0071] Embodiment 2: This example provides a kind of superhydrophobic polyolefin hollow fiber membrane that is used for oxygenation membrane, and its preparation method comprises the steps:

[0072] (1) Prepare casting solution 1: add 55wt% isotactic polypropylene, 20wt% didecyl phthalate, 22wt% dioctyl adipate, and 3wt% dehydroabietic acid alkali metal salt In a high-temperature container, heat and stir at 190° C. for 6 hours to obtain a uniform polymer solution, and stand at constant temperature for vacuum defoaming before use.

[0073] (2) Prepare casting solution 2: add 32wt% isotactic polypropylene, 48wt% glycerol triacetate and 20% di-n-octyl phthalate into a high-temperature container, heat and stir at 190°C for 5h to obtain a uniform The polymer solution was left to stand at constant temperature for vacuum defoaming before use.

[0074] (3) Use a metering pump to quantitatively feed the casting solution 1 to the outermost channel of the three-channel spinneret; use a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com