Process for treating printing and dyeing wastewater through combination method

A printing and dyeing wastewater and treatment process technology, applied in the field of water treatment, can solve the problems of high cost, large dosage of chemicals, and a lot of solid waste, and achieve the effects of less dosage, good decolorization effect, and high COD removal rate

Inactive Publication Date: 2014-02-12

HUBEI CHUANDONG ENVIRONMENTAL ENERGY DEV CO LTD

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the coagulation method has problems such as large dosage of chemicals, high cost, and more solid waste generated.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0014] Below in conjunction with specific embodiment, further set forth the present invention

[0015] See the aforementioned treatment process to further treat the wastewater, not only to meet the discharge standards, but also to directly reuse it.

[0016] The data before and after wastewater treatment are shown in the table below:

[0017] project

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

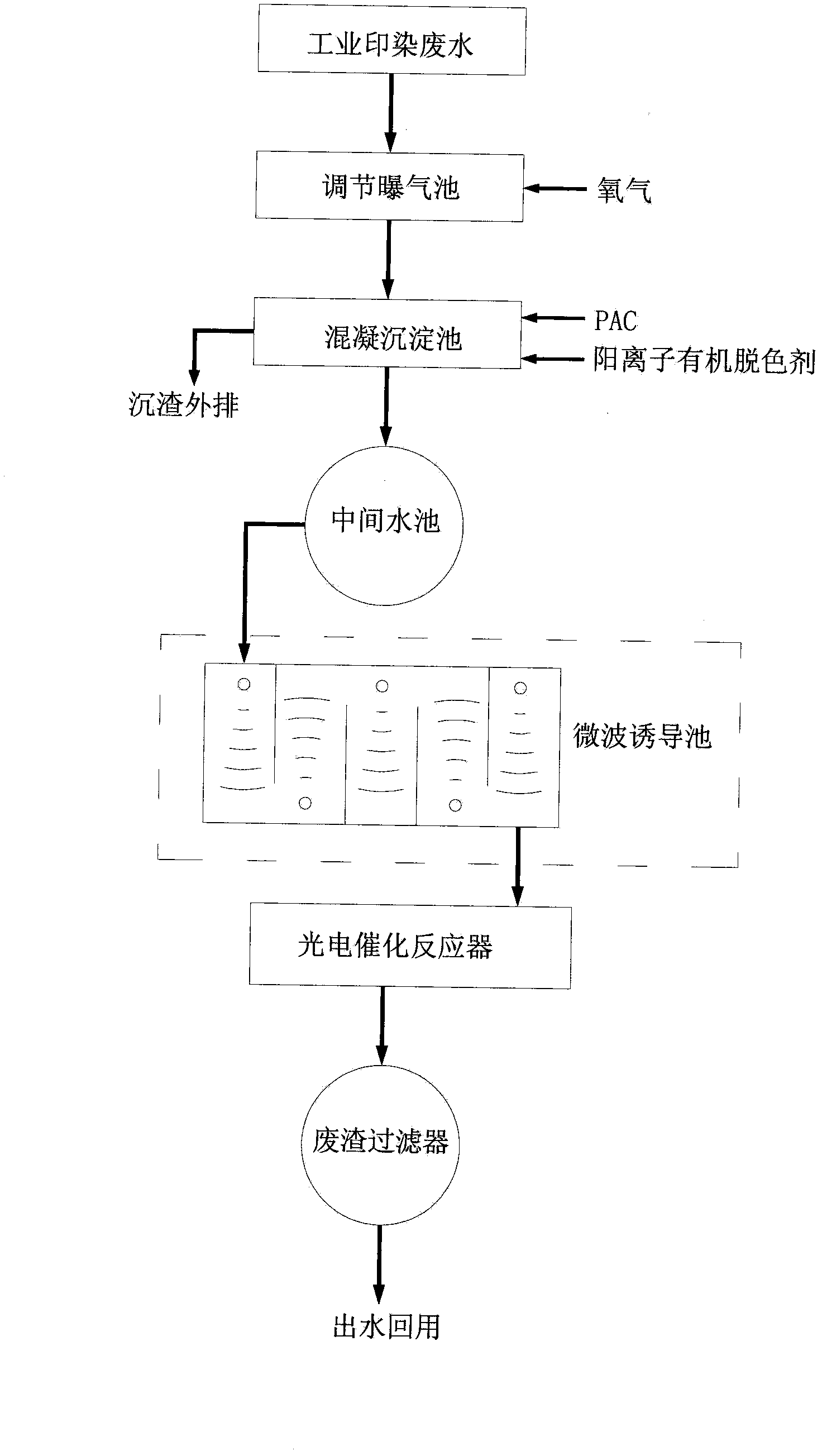

The invention relates to a process for treating printing and dyeing wastewater through a combination method. The process comprises a pretreatment process and a combined treatment process, wherein the pretreatment process comprises the following steps: regulating an aeration process and a neutralization, coagulation and precipitation process, performing pretreatment of aeration regulation and neutralization, coagulation and precipitation on wastewater, and performing combined treatment through microwave+photoelectrocatalysis+industrial waste residue filtration and adsorption. According to the process, degradation-resistant organic matters and other pollutants in the printing and dyeing wastewater can be effectively degraded, a wastewater treatment effect is improved, and the treated wastewater can basically meet the reutilization requirement. According to the process, related problems (particularly complex pollutant components, low biodegradability and high discoloring difficulty of the mixed printing and dyeing wastewater in a concentrated industrial park) for treatment of the printing and dyeing wastewater are effectively solved, a high-efficiency treatment process is provided, the treatment effect is stable, the production operating cost is low, and the operation is simple and convenient.

Description

technical field [0001] The invention belongs to the field of water treatment, and in particular relates to a combined method for treating printing and dyeing wastewater. Background technique [0002] my country is the largest country in the world's textile printing and dyeing industry, and the textile printing and dyeing industry is a large industrial wastewater discharge, accounting for about 35% of the entire industrial wastewater discharge. According to incomplete statistics, printing and dyeing factories will produce 3 to 5 tons of wastewater for every 100m of fabric processed. Printing and dyeing wastewater has become the most harmful and difficult to control important pollution source due to the entrainment of the fiber raw material itself and the slurry, oil, dyes and chemical auxiliaries used in the processing process. With the development of the chemical properties of modern dyes and auxiliaries towards anti-oxidation, anti-photochemical and anti-biochemical, the t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F9/06C02F1/72C02F1/28C02F1/30

Inventor 郭世平喻小平徐晶晶

Owner HUBEI CHUANDONG ENVIRONMENTAL ENERGY DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com