Process for treating jet weaving wastewater

A wastewater treatment and process technology, which is applied in the field of water jet weaving wastewater treatment process, can solve the problems of failing to meet environmental protection requirements, water turning black and smelly, water pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

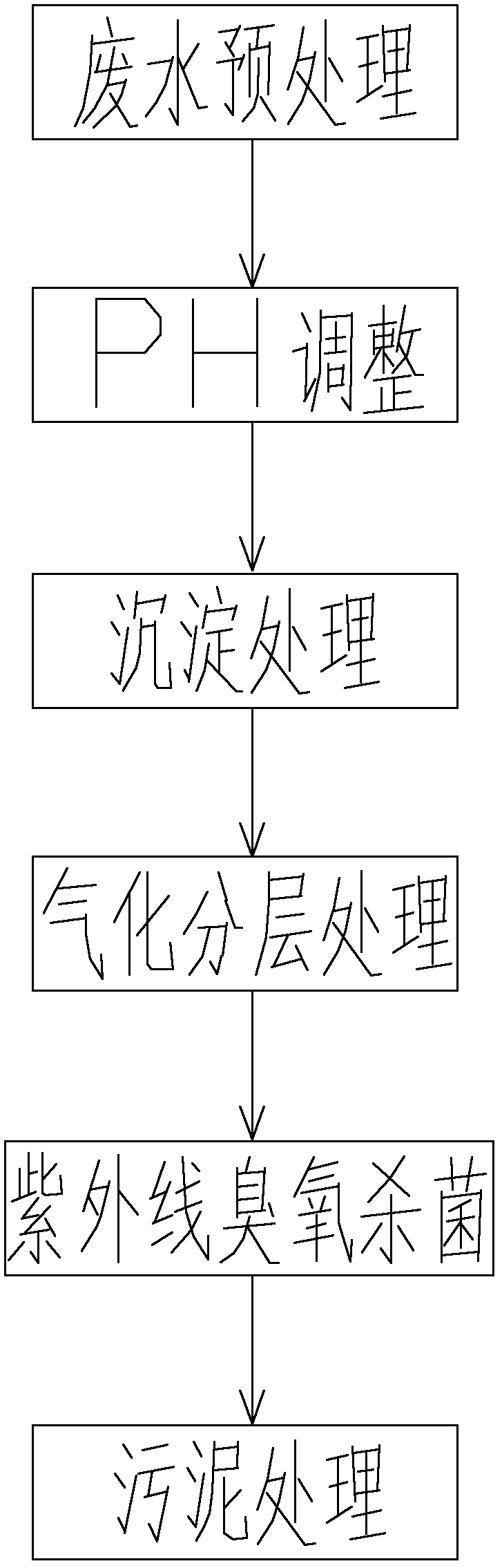

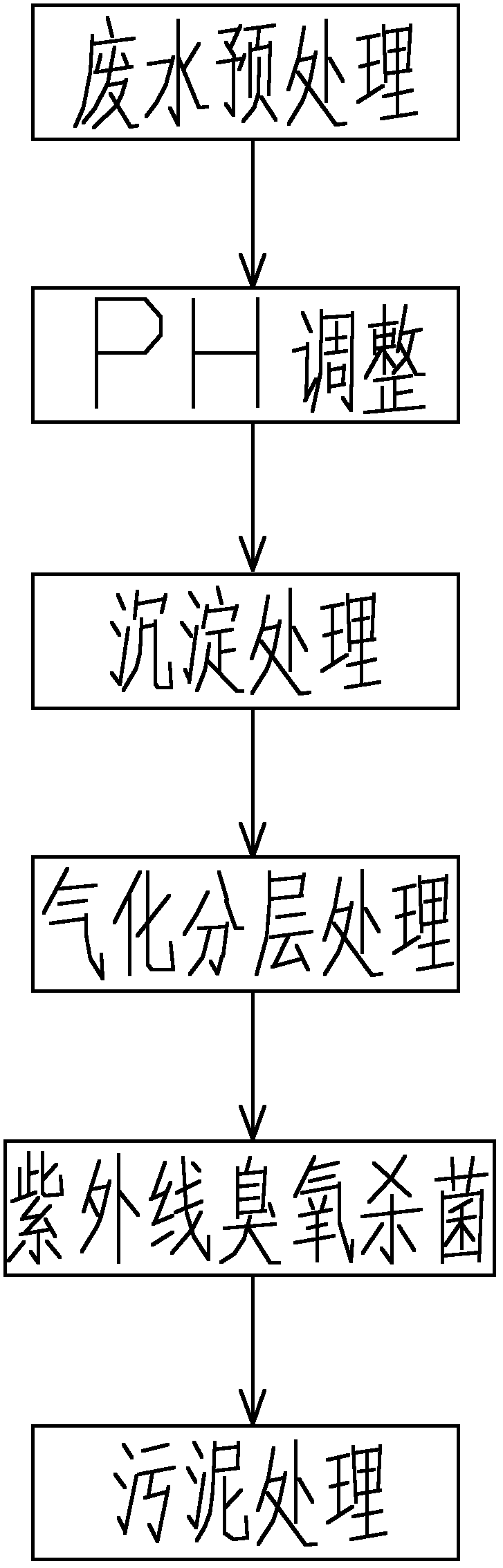

Image

Examples

Embodiment Construction

[0018] Such as figure 1 Shown, a kind of jet weaving waste water treatment process comprises the following steps successively:

[0019] a) Wastewater pretreatment: The spray weaving wastewater is cut off by a fixed grid to cut off large particles of suspended impurities such as waste silk, waste cloth, and garbage with a particle size greater than 5mm, and then flows into the waste water pool by itself. The suspended oily impurities in the waste water pool float on the The liquid level, the pretreated water is obtained after the suspended oil impurities are removed by oil separation, and the pretreated water is lifted by the lift pump into the pH adjustment tank;

[0020] b) PH adjustment: use a stirrer to add PAC agent to the pretreated water in the water inlet pipe, and then add NaOH to the pH adjustment tank to neutralize the acid and alkali to keep the pretreated water in a neutral state; the PAC agent is polymerized chlorine For aluminum, a blower can be used to blow air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com