Integrated slurry-water separation system of shield tunneling machine

A mud-water separation and shield machine technology, applied in filtration separation, separation methods, water/sludge/sewage treatment, etc., can solve the difficulty of meeting the requirements of urban sewage discharge standards, waste of resources, shield cost, endangering the ecological environment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

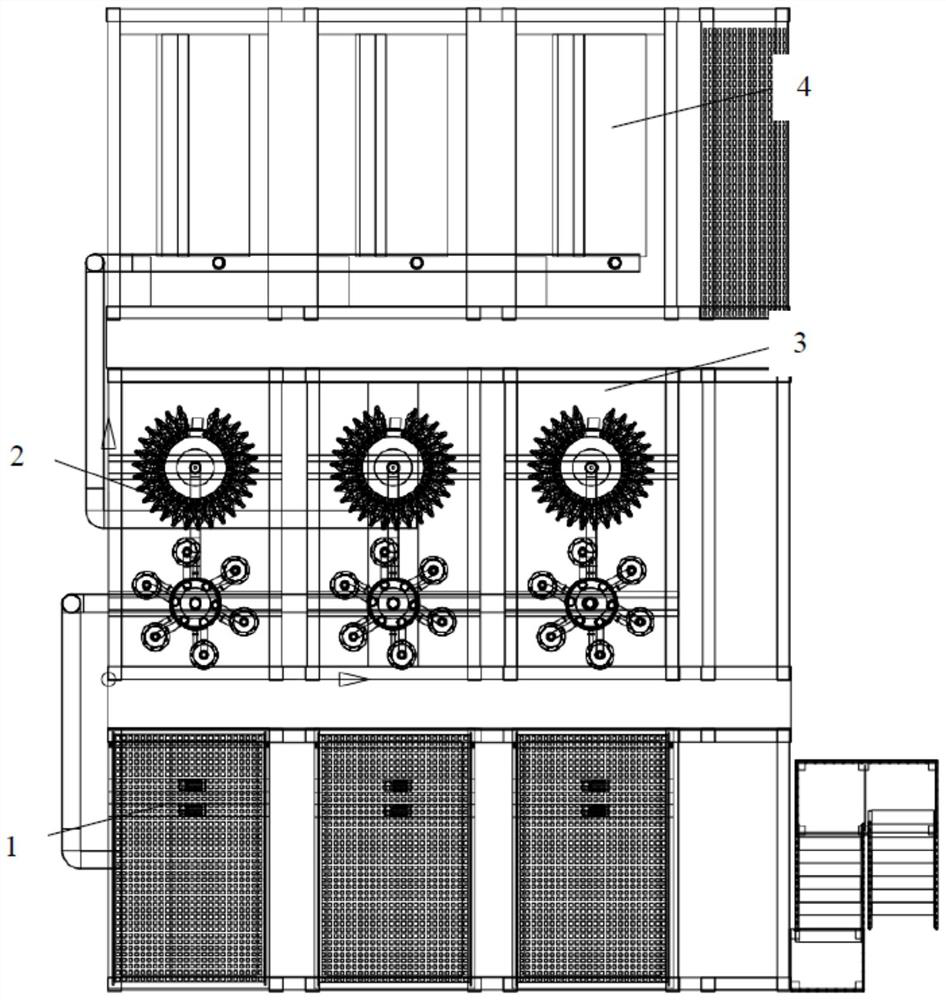

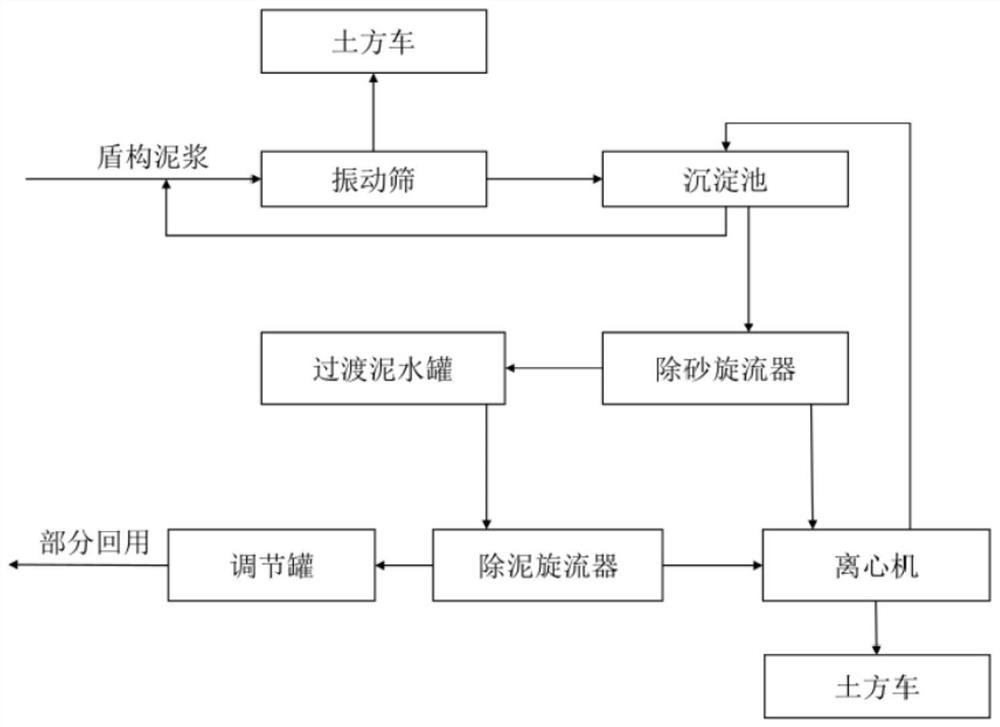

[0032] like Figure 1 to Figure 3 As shown, the vibrating screen system is the first primary separation, mainly for pretreatment of muddy water to dehydrate and remove coarse particles such as agglomerates and blocks. The separation of coarse particles adopts three-layer vibrating sieve. Particles with a particle size of less than 10mm pass through the first layer of vibrating sieve and enter the second layer. Particles with a particle size of less than 6mm enter the third layer of vibrating sieve after being vibrated. Pool, vibrating sieve all screened materials are discharged to the soil pile site.

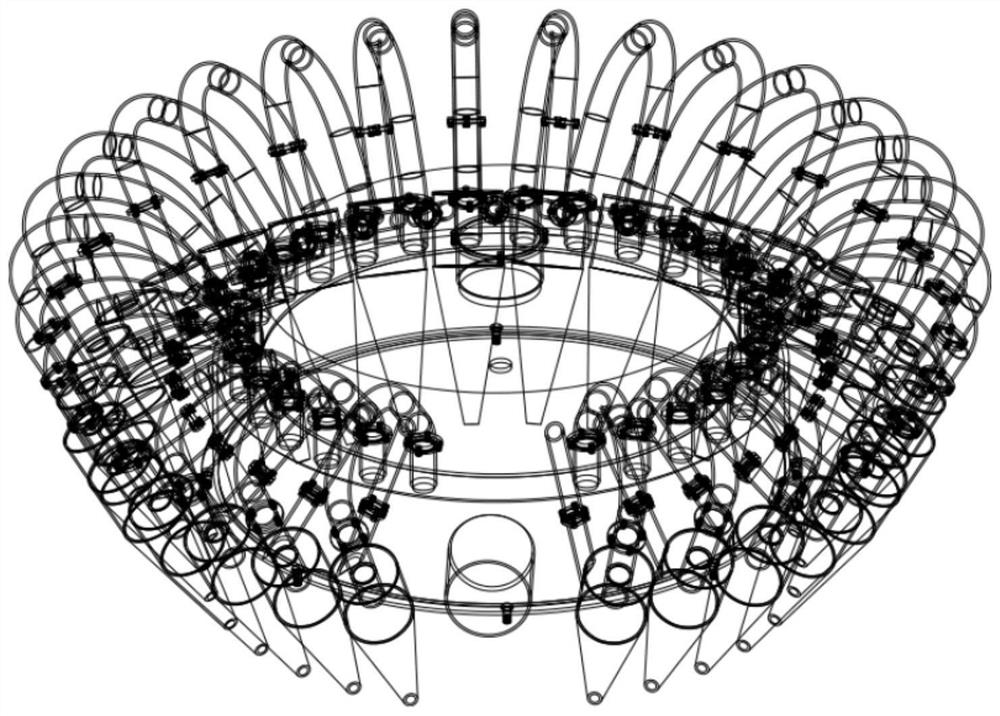

[0033] The main function of the cyclone separation system is to refine the medium and fine particle slurry separated by the vibrating screen again, gradually reduce the particle size of the slurry, and use two-stage cyclone for processing, which are desanding cyclone and cyclone respectively. The desilter cyclone adopts a static cyclone, which is mainly composed of a cylinder a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com