Recyclable sewage treatment device and treatment method

A sewage treatment device and sewage technology, applied in the direction of light water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. pollution and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

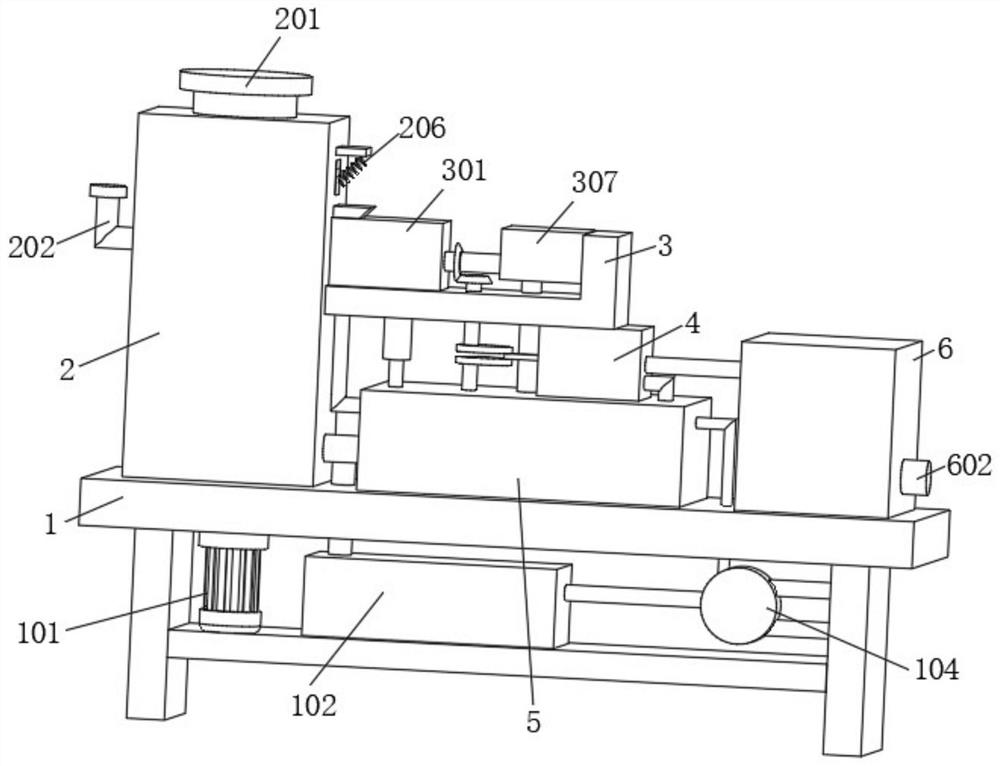

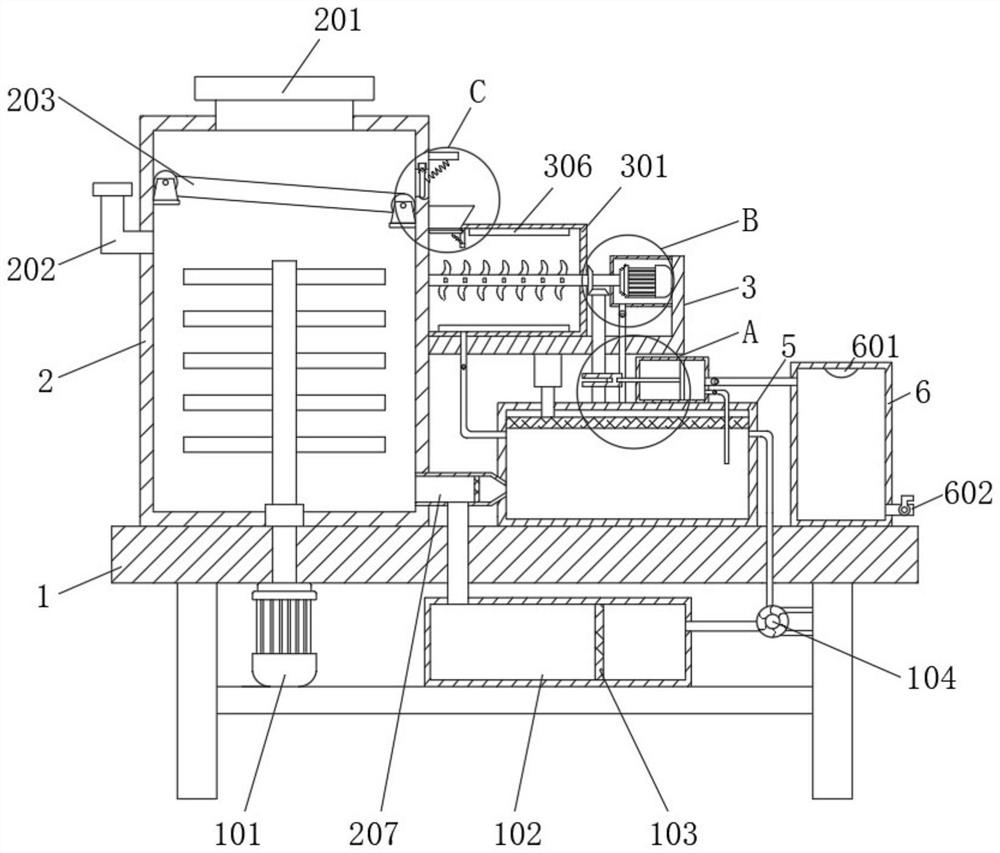

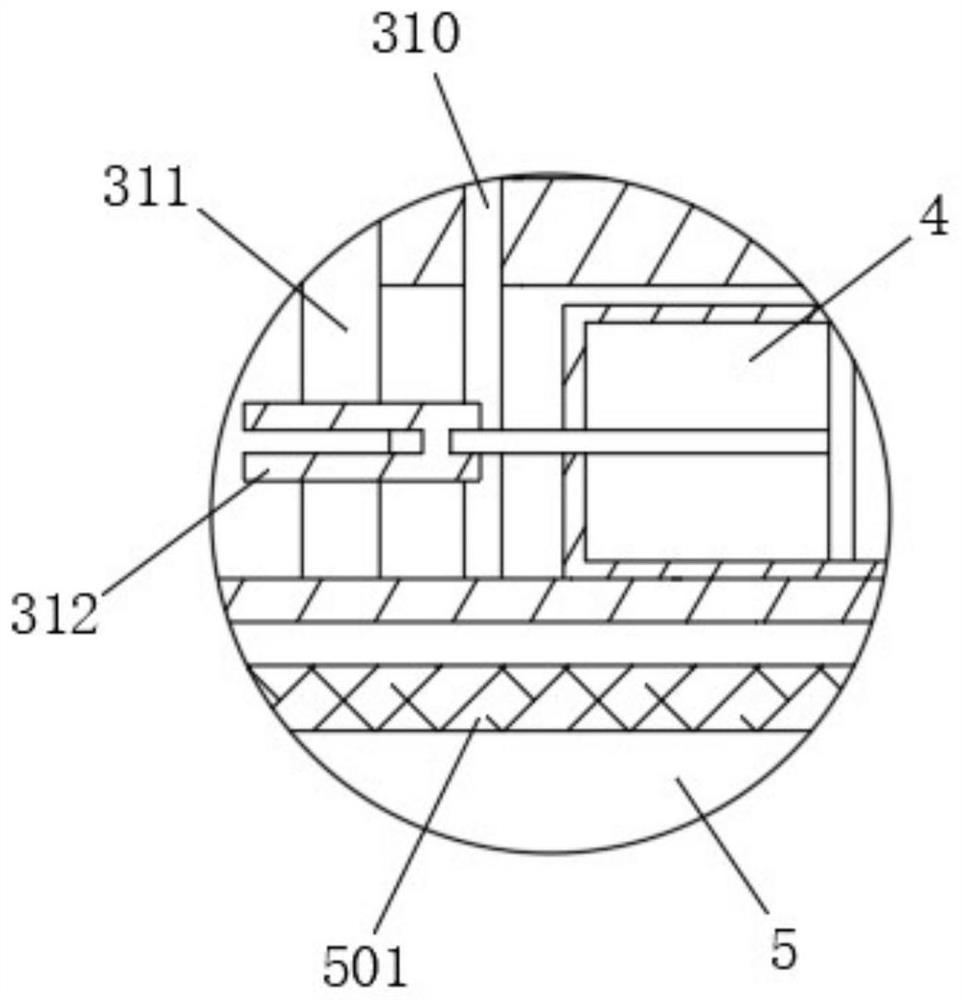

[0038] refer to Figure 1-5, a recyclable sewage treatment device, comprising a support base 1, a first treatment box 2 and a second treatment box 5, the first treatment box 2 and the second treatment box 5 are fixedly connected to the top of the support base 1, and Including: a support plate 3, fixedly connected to the side wall of the first processing box 2; a crushing box 301, fixedly connected to the top of the support plate 3; a heating plate 306, fixedly connected to the inner wall of the crushing box 301, used for The rubbish in the case 301 is dried to facilitate its crushing; the conduit is connected between the crushing case 301 and the second processing case 5, and is used to transfer the heat in the crushing case 301 to the second processing case 5, so that the second The temperature in the treatment box 5 rises, and the buoyancy of the sewage decreases, so that the fine flocculent floating matter settles to the bottom of the box.

[0039] When carrying out sewage...

Embodiment 2

[0041] refer to Figure 1-2 , is basically the same as Example 1, furthermore, in order to carry out preliminary treatment to the sewage, the top of the first treatment tank 2 is provided with a water injection port 201, and the side wall of the first treatment tank 2 is provided with an injection port 202, and the support seat The bottom of 1 is connected with a first motor 101, the output end of the first motor 101 is connected with a stirring shaft, the end of the stirring shaft away from the first motor 101 is connected in the first processing box 2, and the outer wall of the stirring shaft is provided with multiple sets of stirring teeth .

[0042] A connecting pipe 207 is connected between the first treatment box 2 and the second treatment box 5, and a filter plate is arranged in the connecting pipe 207. The bottom of the support seat 1 is fixedly connected with a filter box 102, and the filter box 102 and the connecting pipe 207 are connected. There are branch pipes, t...

Embodiment 3

[0045] refer to figure 1 , figure 2 , Figure 4 with Figure 5 , is basically the same as Embodiment 1, furthermore, in order to filter the garbage in the sewage, the inner walls on both sides of the first treatment box 2 are connected with fixing plates, and a filter conveyor belt 203 is connected between the two sets of fixing plates , the side wall of the first processing box 2 is connected with the opening 204 corresponding to the position of the screen conveyor belt 203, the opening 204 is connected with the first rotating plate 205 in rotation, and the outer wall of the first processing box 2 is fixedly connected with the first rotating plate 205 The support plate at the corresponding position, the first spring 206 is connected between the first rotating plate 205 and the support plate.

[0046] The top of the crushing box 301 is provided with a feed port 302 corresponding to the position of the opening 204, the inner wall of the crushing case 301 is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com