Comprehensive treating method and treating system for industrial aquatic cultivation sewage

A technology for comprehensive treatment and aquaculture, applied in the field of comprehensive treatment methods and treatment systems for industrialized aquaculture wastewater, can solve problems such as high cost, difficult management, complicated wastewater treatment systems, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

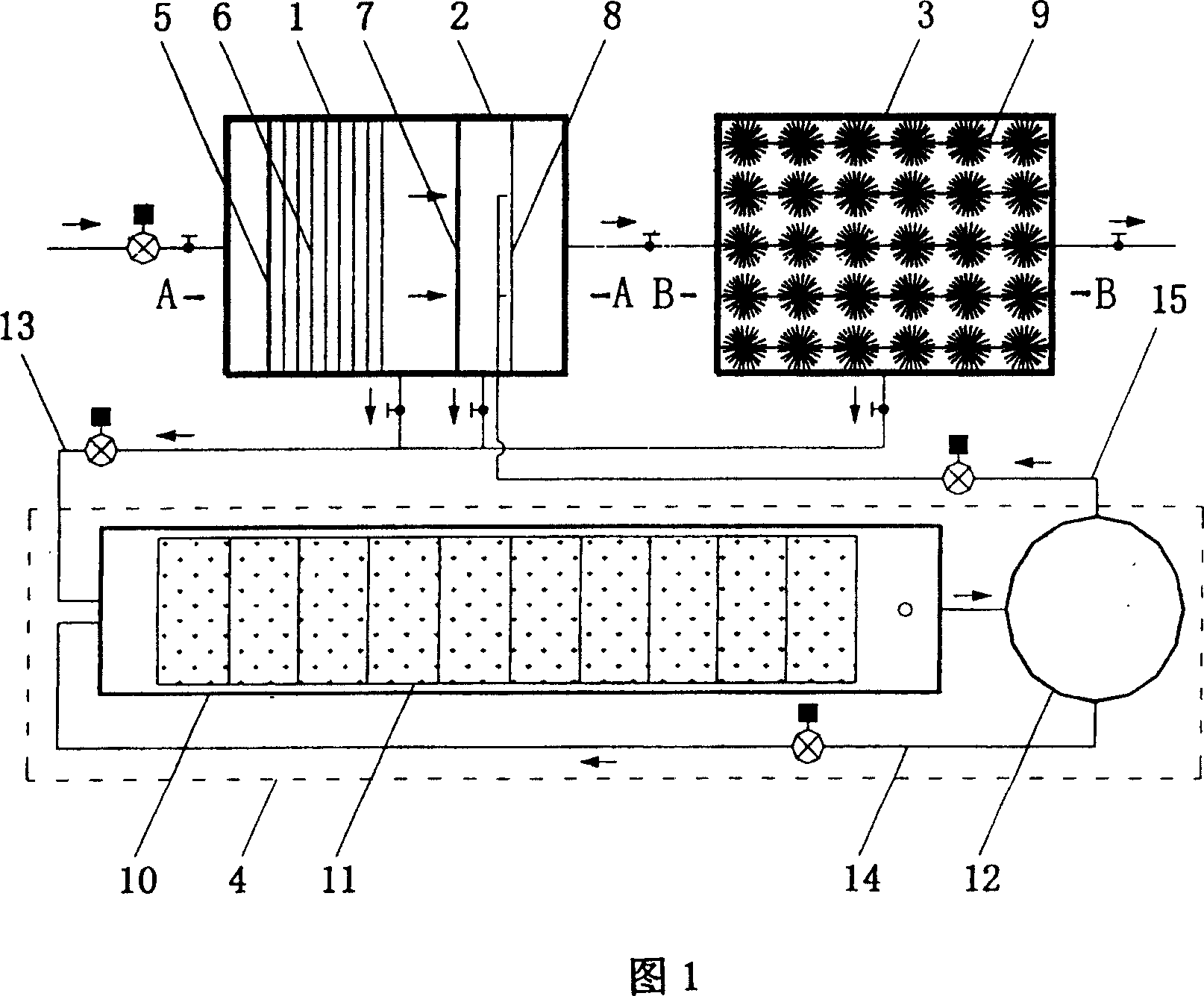

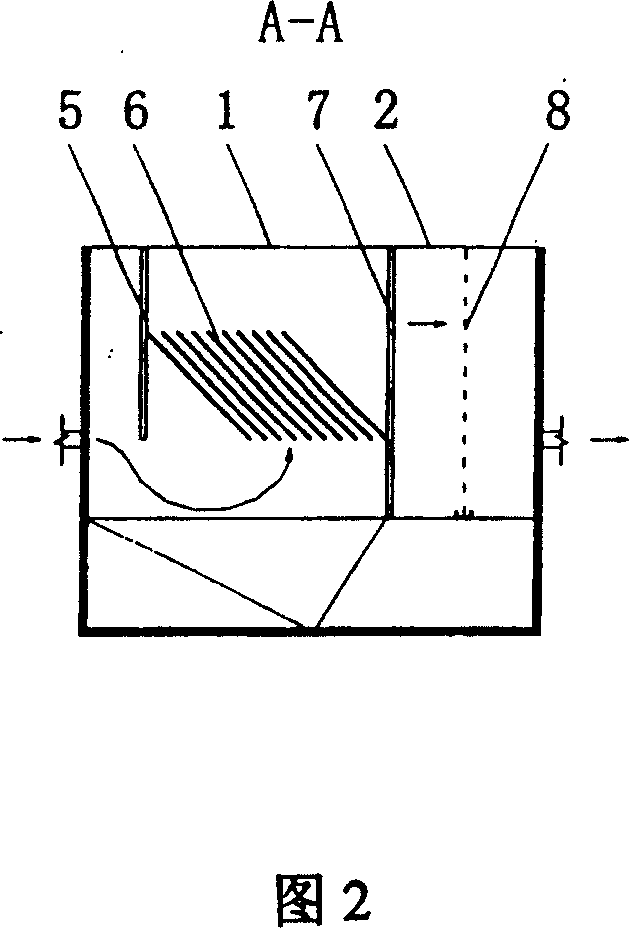

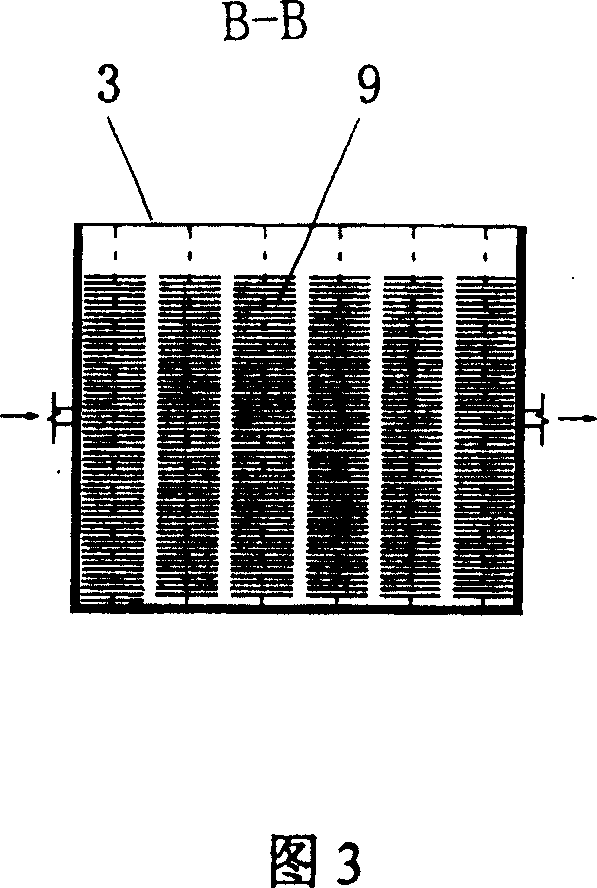

[0036]As shown in Figure 1, Figure 2, and Figure 3, the waste water is input into the treatment system through the pump controlled by the relay, and the inclined plate settler 1 and the mechanical filter 2 are concentrated in a 1200×900×1000mm (length×width×height) treatment pool , the inflow baffle plate 5 of the inclined plate settler 1 is 500 mm high, and the top is flush with the top of the treatment tank. The inclined plate 6 has a length of 390 mm and an inclined angle of 45°. A total of 10 inclined plates form a 9-layer channel, and the distance between adjacent inclined plates is 40 mm. The top of the inclined plate is 220mm away from the top of the treatment tank. The bottom of the inclined plate settler 1 is inclined on three sides to facilitate the concentration and discharge of sediment. The depth of the lowest point is 1000mm, and the height difference of the slope is 300mm. The bottom surface of the mechanical filter 2 is flush with the highest point of the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com