A cellulose nanocrystal-loaded chitosan adsorbent and its application in recycling rare earth elements from sewage

A technology loaded with chitosan and nanocrystals, applied in the field of environmental engineering, can solve the problems of inhibiting the biological activity of activated sludge, increasing the cost of incineration ash treatment, etc., and achieve the effect of meeting the requirements of recycling, high feasibility, and broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1: Dehydration and drying of papermaking deinking sludge

[0051] Obtain 10L of papermaking deinking sludge mixed solution from the deinking wastewater treatment process section of the papermaking wastewater treatment site (a paper mill in Jiaxing), take out 500ml of muddy water mixed solution (6 parallel samples are set) under the premise of uniform stirring, and use it after centrifugation Phosphate buffer with pH 7.0 was repeatedly diluted 3 times, and finally the volume was adjusted to 500ml. Three groups of parallel samples were taken out, and after suction filtration, the sludge samples retained on the filter membrane were placed in an oven and dried at 105°C for 4 hours, and then the dry weight of the papermaking deinking sludge was calculated. Take out other 3 groups of parallel samples, add to 500ml mud-water mixture successively the FeCl3 that is sludge dry weight 5% and the slaked lime that is sludge dry weight 20%, through 2min fast stirring (rotatin...

Embodiment 2

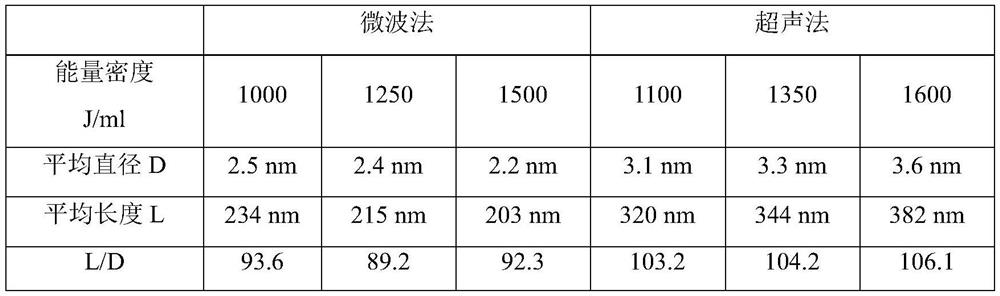

[0052] Example 2: Oxidation of papermaking deinking drying sludge and separation of cellulose nanocrystals

[0053] Select the crushed papermaking deinking and drying sludge in the parallel sample, rinse the crushed sludge with a phosphate buffer solution with a pH of 7.0, make the volume of the mixed solution reach 100ml, and keep stirring at a speed of 150r / min , add 60mg of 0.2mmol of 2,2,6,6-tetramethylpiperidinium oxide radical (TEPMO) and 80mg of 5.0mmol of NaBr in turn, after TEPMO and NaBr are completely dissolved, slowly add 8.0mmo / L of NaClO solution until the pH of the reaction system does not change, then stop the reaction with a slight excess of absolute ethanol, and finally obtain cellulose nanocrystals through microwave separation and centrifugal precipitation.

Embodiment 3

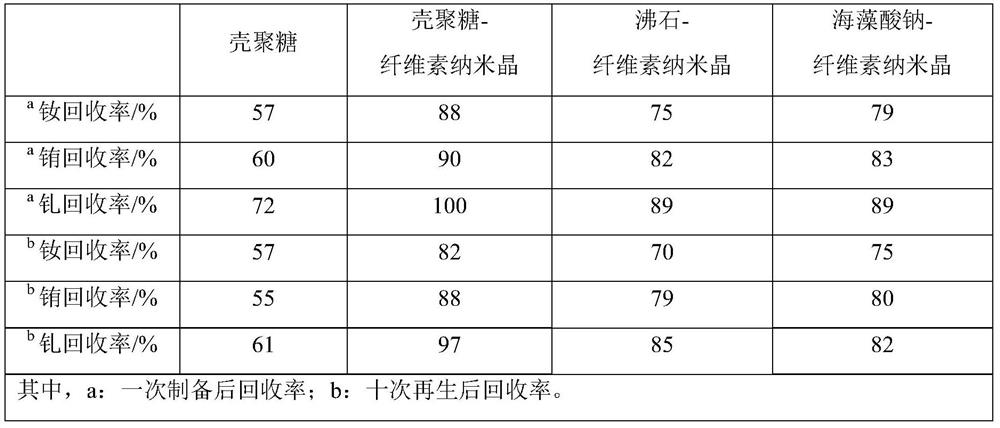

[0054] Embodiment 3: the establishment of chitosan-cellulose nanocrystal system

[0055] Under the slightly acidic condition provided by acetic acid, put 2g of low-viscosity chitosan (viscosity lower than 0.22Pa·s) into 100mL of acetic acid solution (pH=4.0), and keep stirring under the condition of rotating speed of 150r / min to make it appear Uniformly dispersed state to form chitosan-acetic acid mixture. Dissolve 0.2 g of the prepared cellulose nanocrystal in 100 mL of acetic acid solution (pH=4.0), slowly add it into the chitosan-acetic acid mixture after stirring and mixing, and then mix the obtained chitosan-cellulose nanocrystal The crystal mixture was dried in an oven at low temperature (75° C.) for 24 hours, and the moisture was balanced for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com