Polyethylene glycol modified protein and method for purification of modified product

A polyethylene glycol and protein technology, applied in the field of modification and purification of polyethylene glycol, can solve the problems of low product yield and many steps, and achieve the effect of high product yield, simple method and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1 is used for the buffer replacement of the asparaginase of PEG modification, modification reaction and modification product purification

preparation example 1

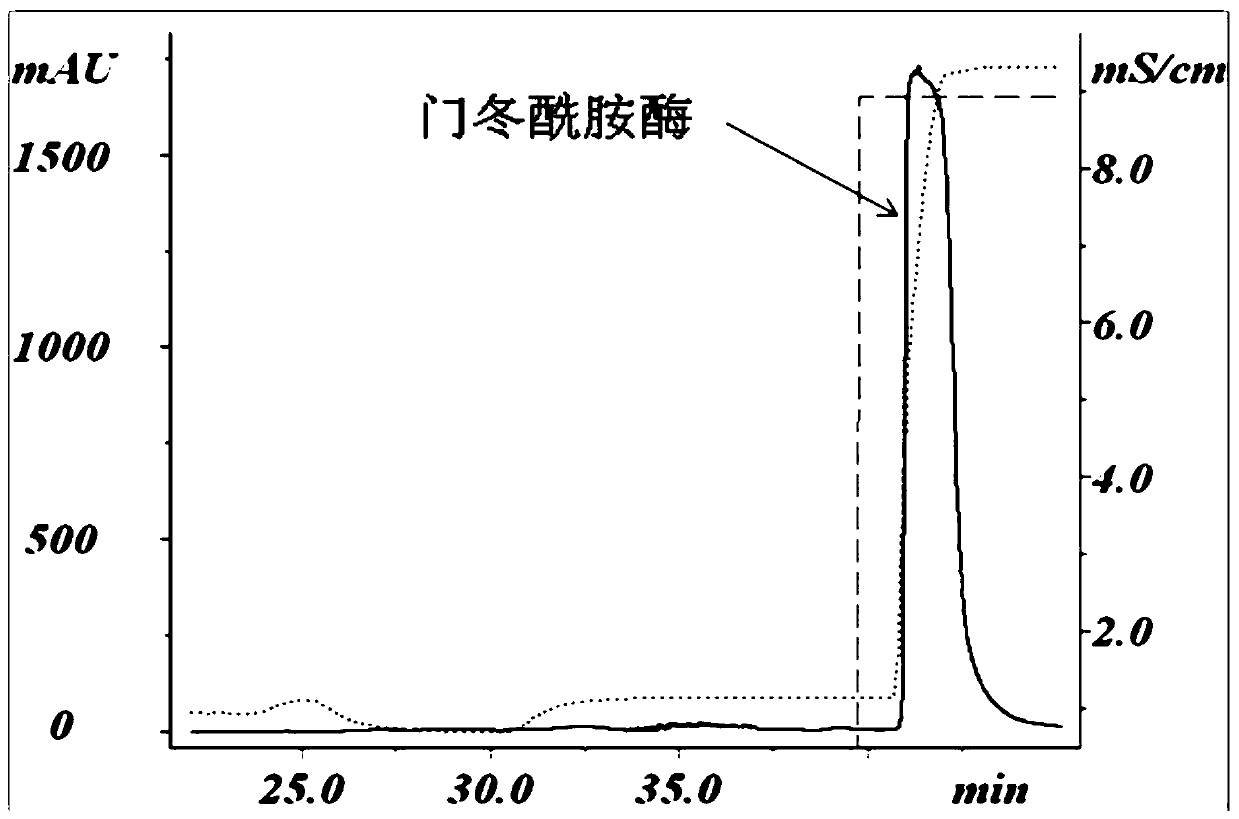

[0068] Step 1: Buffer Exchange

[0069] The freeze-dried powder of asparaginase was dissolved in 20 mM Tris-Hcl (pH 8.0) buffer solution to prepare a solution with a protein concentration of 5 mg / ml. Then the sample was loaded through the sample pump of the AKTA chromatography system, and the sample was drawn into the Q ion exchange column (purchased from GE, HiTrap Q HP 5mL). After loading the sample, equilibrate the chromatographic column with equilibration buffer A. After equilibrating for 5 column volumes, perform one-step elution with elution buffer B, and collect the elution peaks.

[0070] (A solution: 20mM phosphate buffer (pH8.0); B solution: 20mM phosphate buffer + 0.2M sodium chloride (pH7.5)

[0071] Step 2: Modification reaction and purification of modified products

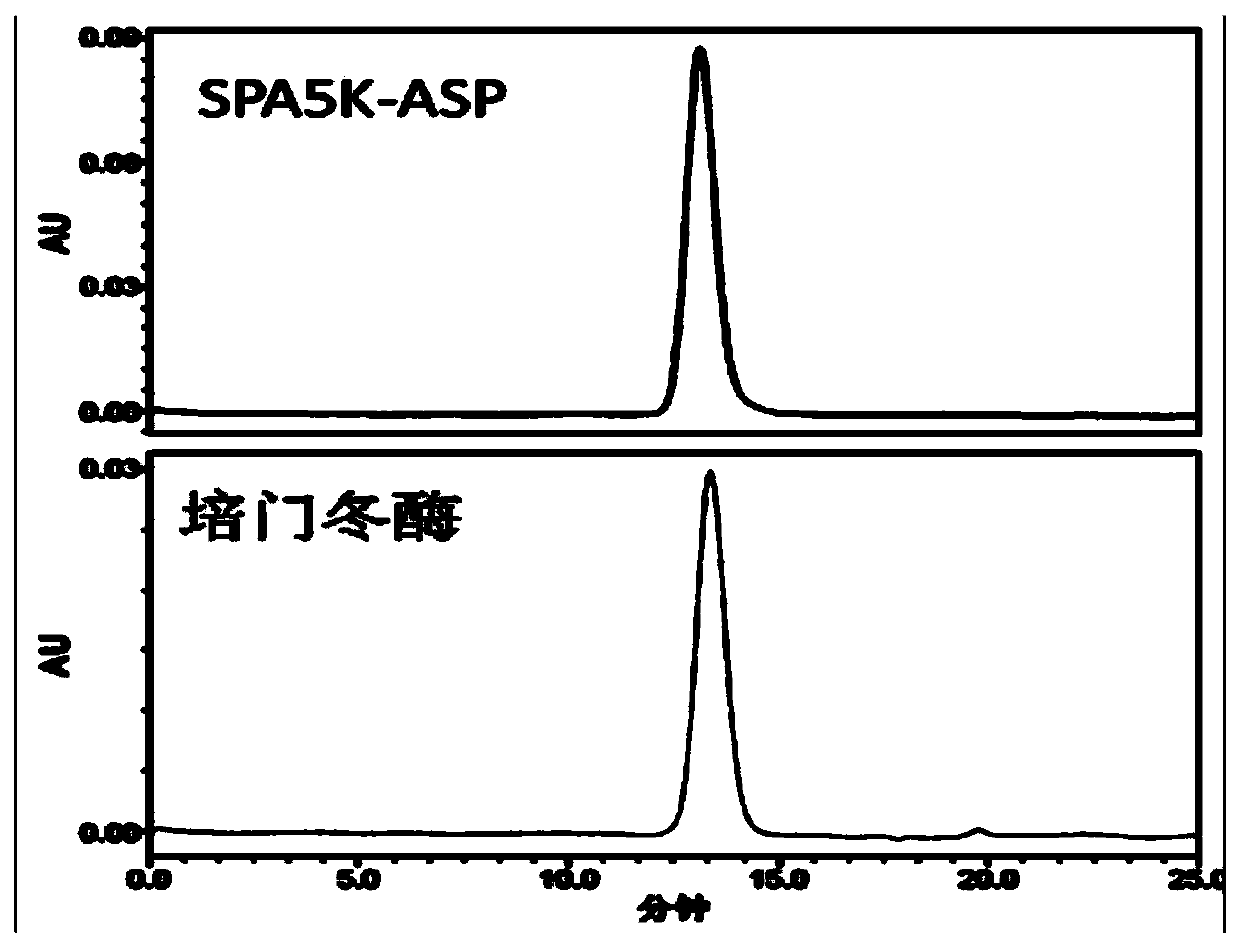

[0072] Using M-SPA-5000 (purchased from Beijing Jiankai Technology Co., Ltd.) as a PEG modifier, the asparaginase solution of the elution peak collected in the first step was asparaginase: PEG modi...

Embodiment 2

[0091] Embodiment 2: Carry out the PEG modification buffer replacement of asparaginase by conventional method, modification reaction and modification product purification

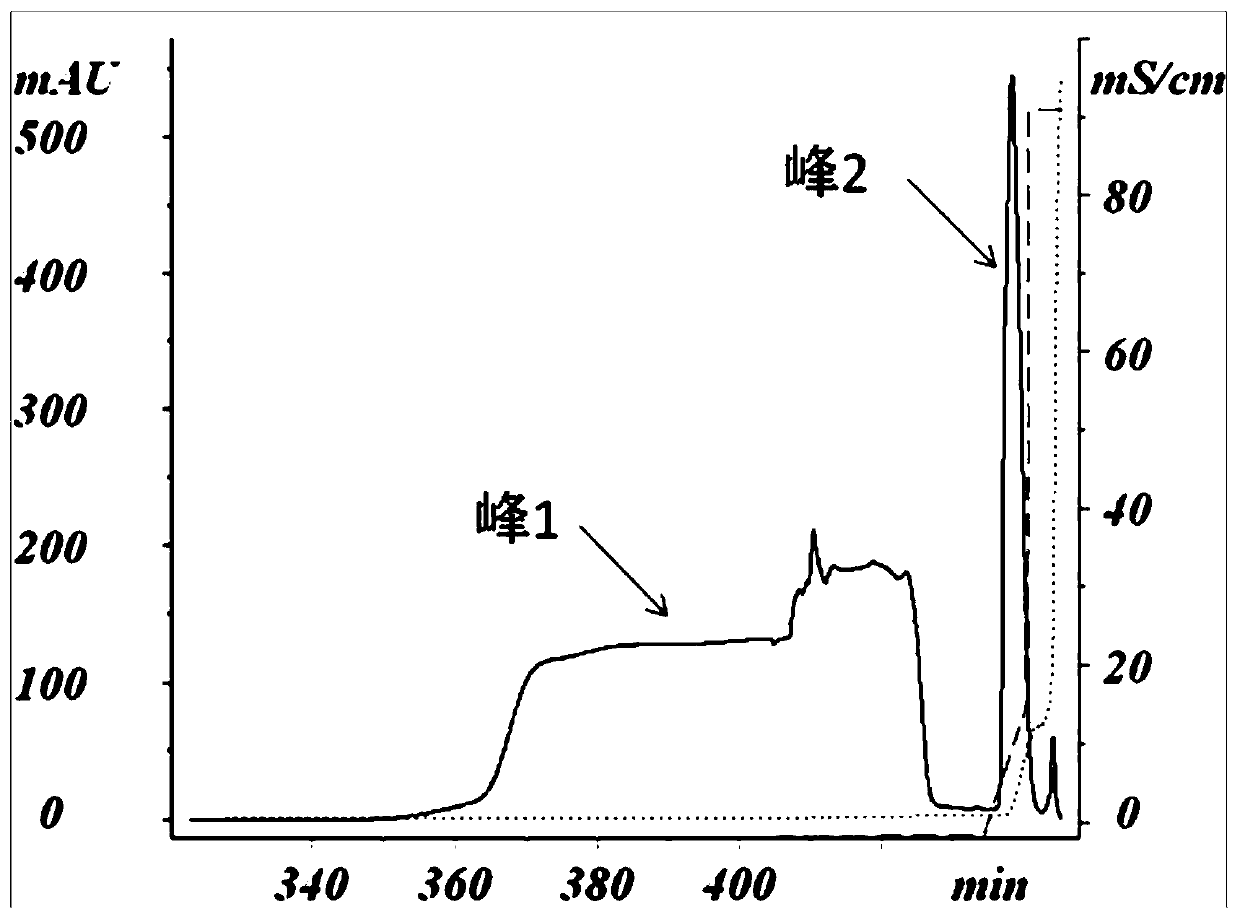

[0092] Step 1: Buffer Exchange

[0093] The freeze-dried powder of asparaginase was dissolved in 20 mM Tris-Hcl (pH 8.0) buffer solution to prepare a solution with a protein concentration of 5 mg / ml. The dissolved asparaginase protein solution was buffer exchanged with an ultrafiltration system (Sartorius Vivaflow 20P0), and finally replaced into a pH 7.0 phosphate buffer. After the ultrafiltration, it was found that the retentate was turbid, indicating that a precipitate was formed. Next, filter the retentate with a 0.22um membrane, and the filtered solution is clarified.

[0094] Step 2: Modification reaction and purification of modified products

[0095] Use M-SPA5000 as a PEG modifier, add the modifier to the asparaginase solution after ultrafiltration and filtration, and react according to the molar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com