Method for recycling acid and heavy metal in gold smelting acid wastewater

A technology for acidic wastewater and heavy metals, applied in chemical instruments and methods, alkali metal compounds, alkali metal sulfites/sulfites, etc., can solve problems such as high cost, high energy consumption, and insignificant benefits, and reduce emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

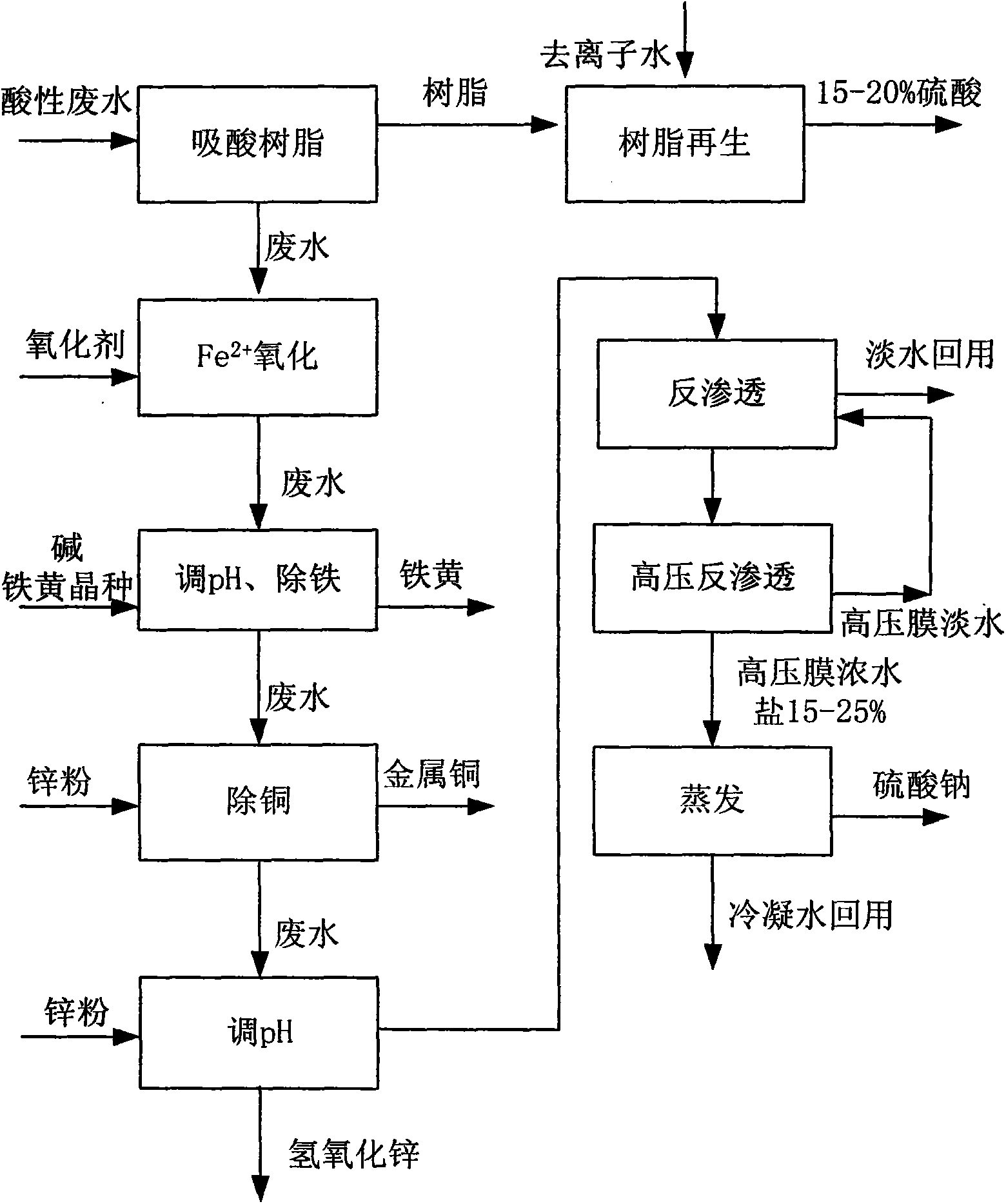

Image

Examples

Embodiment 1

[0009] The pickling waste water of a gold smelter is roughly composed of 5% sulfuric acid, 1% zinc, 0.15% iron, 0.03% copper, 2% sodium, 0.02% magnesium, 0.01% calcium, transparent and slightly yellow, and enters the acid absorption resin bed Adsorbing acid, the acid-absorbing resin is a "tough gel" strong base anion exchange resin with a polystyrene structure containing quaternary amine II functional groups; coupled with hydrogen peroxide oxidation, the divalent iron in the wastewater is oxidized to ferric iron Ions, add iron citrine seeds and heat up to 90°C to react, gradually adjust the pH value to 1.5-4.5, iron yellow precipitates, and obtain iron oxide yellow after filtering; add zinc powder to replace the copper in the wastewater after removing iron yellow, Remove copper and unreacted zinc by filtration; adjust the pH value of the filtered wastewater to 6.5-8.0, and precipitate zinc hydroxide, containing 85-90% zinc hydroxide, which can be sold as crude zinc hydroxide; r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com