Device and method for drying scales by using slab continuous casting afterheat

A technology of continuous casting of iron oxide scale and slab, applied in heating devices, heating to dry solid materials, progressive dryers, etc., to achieve high economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

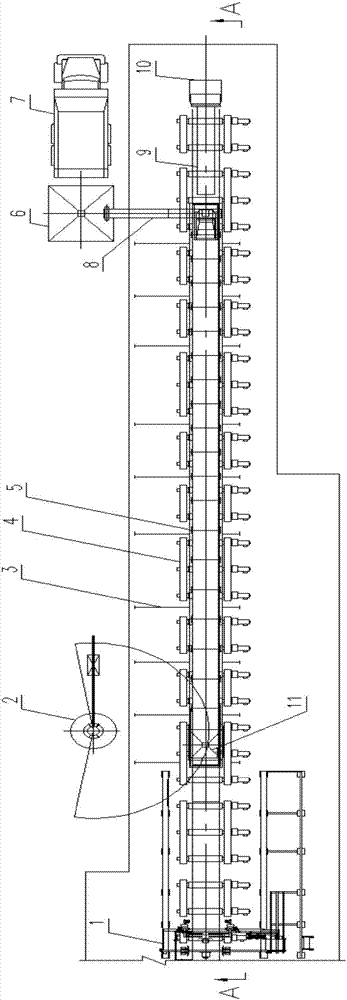

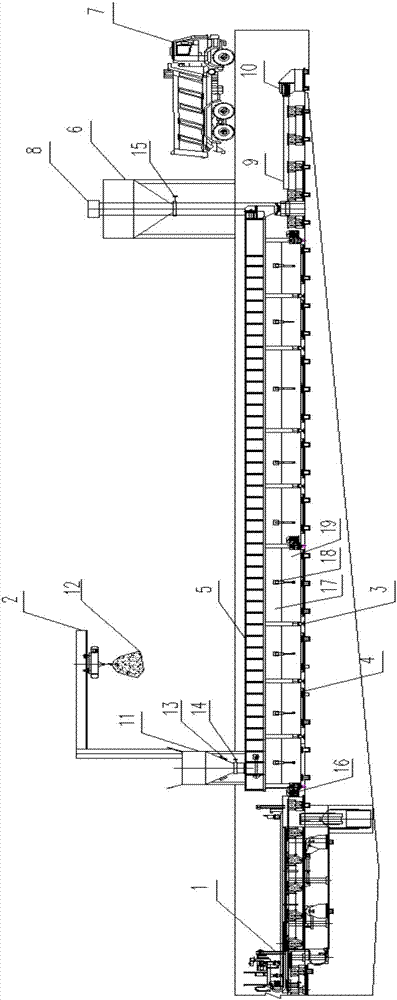

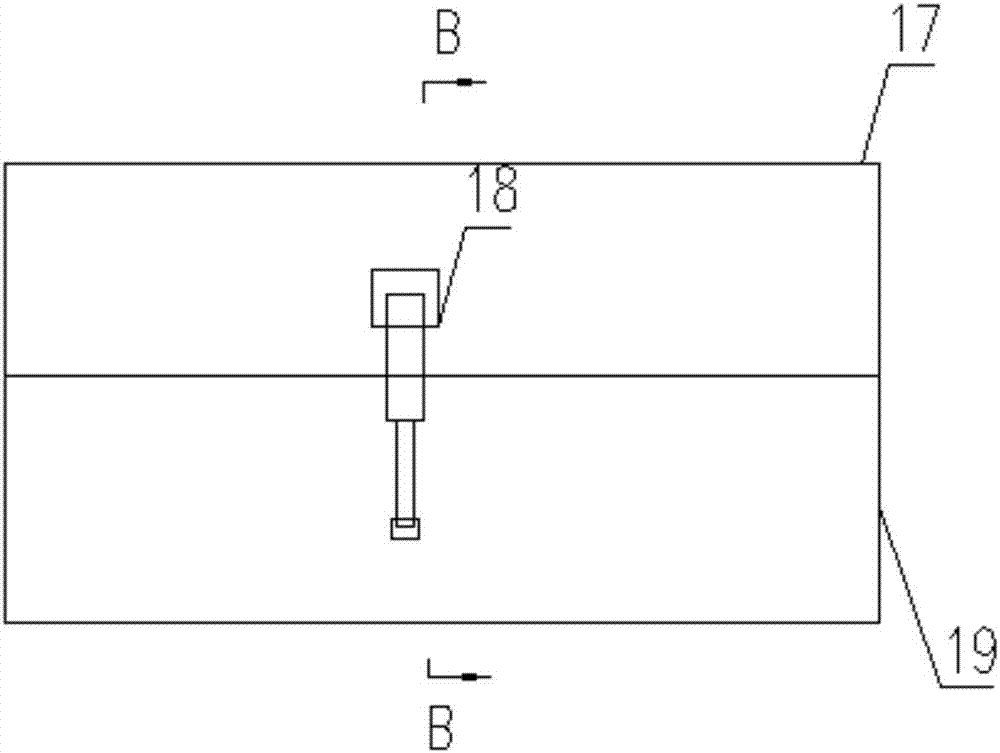

[0022] The following will describe an embodiment of a device and method for drying oxide scale by using waste heat from slab continuous casting according to the present invention with reference to the accompanying drawings. Those skilled in the art would recognize that the described embodiments can be modified in various ways or combinations thereof without departing from the spirit and scope of the invention. Accordingly, the drawings and description are illustrative in nature and not intended to limit the scope of the claims. Also, in this specification, the drawings are not drawn to scale, and like reference numerals denote like parts.

[0023] The flame cutting machine 1 is used to cut the straightened slab into slabs of required length, and the slabs are transferred to the next process by the hot delivery roller table 4 after cutting. Such as figure 1 As shown, the slab moves from left to right. For the convenience of description, the direction in which the slab moves i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com