Polypropylene tail gas recovery device and recovery method

A tail gas recovery and polypropylene technology, applied in the field of polyolefin, can solve the problems of large equipment area, complicated operation, waste of resources, etc., and achieve the effect of small area, low operation energy consumption, and less equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

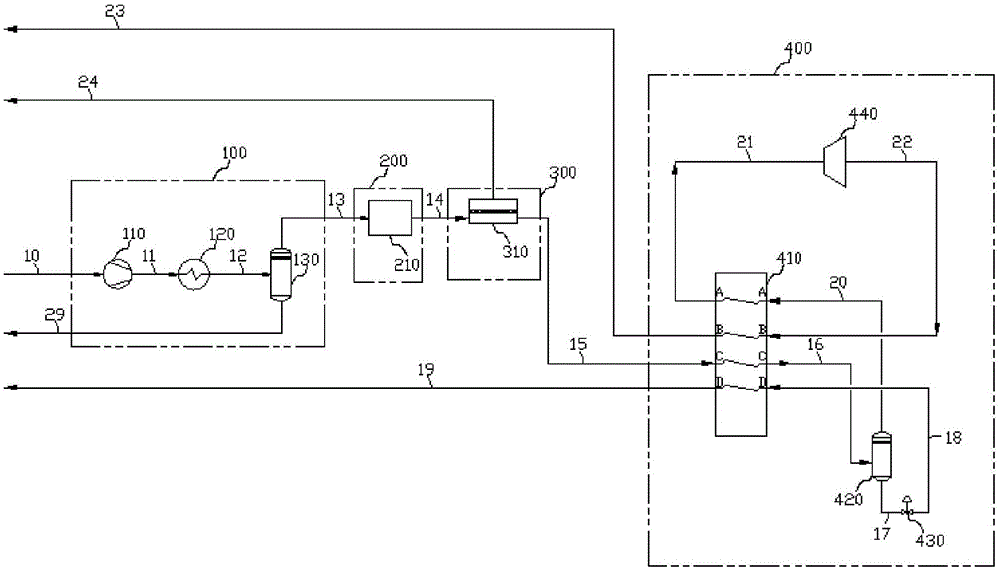

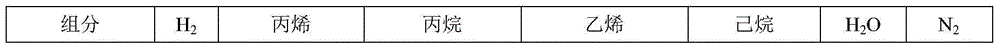

[0041] exist figure 1 In the schematic diagram of the process flow for recovering propylene and nitrogen from polypropylene tail gas shown, the pressure of polypropylene tail gas is 0.05MPa, the temperature is 50°C, and the gas volume is 1000Nm 3 / hr, composed as follows:

[0042] components

H 2

Propylene

Vinyl

h 2 o

N 2

Content%V / V

1.28

8.10

0.10

6.50

0.25

0.27

83.50

[0043] The tail gas first enters the compression unit 100, and the tail gas compressor 110 raises the pressure of the gas to 1.6MPa, and then enters the circulating water cooler 120 to cool the compressed gas to 40°C. The cooled gas enters the normal-temperature gas-liquid separator 130 for gas-liquid separation, and the condensate delivery device obtained at the bottom; the normal-temperature airflow obtained at the top enters the drying unit 200 . In the drying unit, the gas passes through the adsorption tower, t...

Embodiment 2

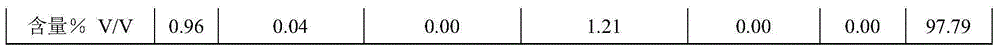

[0054] exist figure 1 In the schematic diagram of the process flow for recovering propylene and nitrogen from the polypropylene tail gas shown, the pressure of the polypropylene tail gas is 0.02MPa, the temperature is 51°C, and the gas volume is 900Nm 3 / hr, composed as follows:

[0055] components

H 2

Propylene

Vinyl

h 2 o

N 2

Content%V / V

0.60

27.67

5.55

1.40

0.00

0.99

63.79

[0056] The tail gas first enters the compression unit 100, and the tail gas compressor 110 raises the pressure of the gas to 1.7MPa, and then enters the circulating water cooler 120 to cool the compressed gas to 40°C. The cooled gas enters the normal-temperature gas-liquid separator 130 for gas-liquid separation, and the condensate obtained at the bottom passes through the delivery device; the normal-temperature airflow obtained at the top enters the drying unit 200 . In the drying unit, the gas passes thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com