Aqueous medium energy transition blasting method and charging cavity

A water medium and charging technology, applied in blasting and other directions, can solve the problems of limited application scope, atmospheric greenhouse effect, troublesome construction process, etc., and achieve the effects of uniform crushing particle size of blasting medium, mitigation of harmful effects, and reduction of unit consumption of explosives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Explosion of explosives is a chemical reaction that occurs instantaneously. This chemical reaction generates new substances and releases a large amount of energy in a very short time. It is very difficult to detect and analyze the explosion of explosives. Therefore, how to analyze the basic principle of explosive explosion is very important to improve the effective utilization of explosive energy. If a "certain amount" of water is added to the "explosion thermodynamic system", according to the laws of thermodynamics, the law of indestructibility of matter (the law of conservation of mass) and the theory of instantaneous detonation, since the explosion of explosives is completed instantaneously, the "explosion thermodynamic system" is too late to match the explosion. The medium undergoes heat exchange, so the "explosion thermodynamic system" can be regarded as an "adiabatic system". Therefore, the energy released by the explosive explosion will be converted into the inter...

Embodiment 2

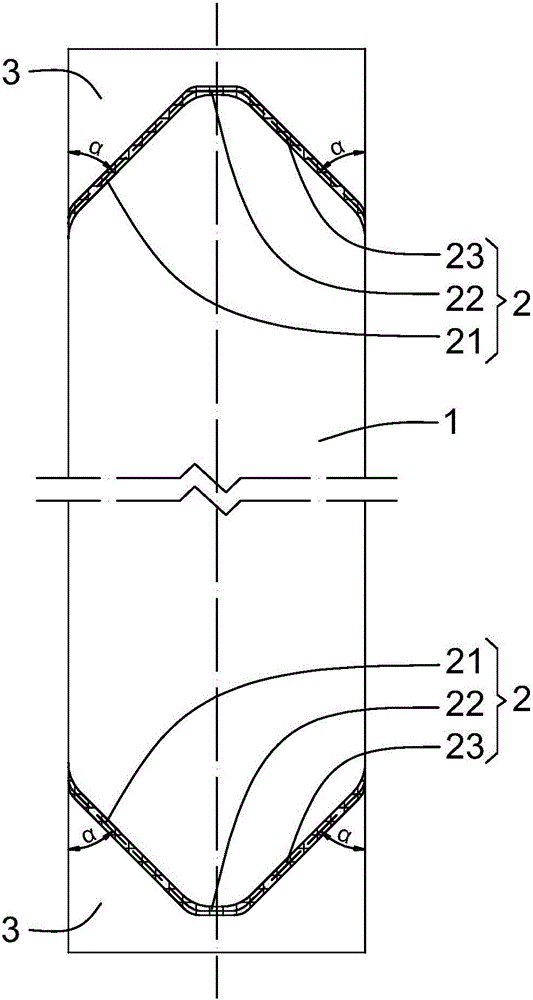

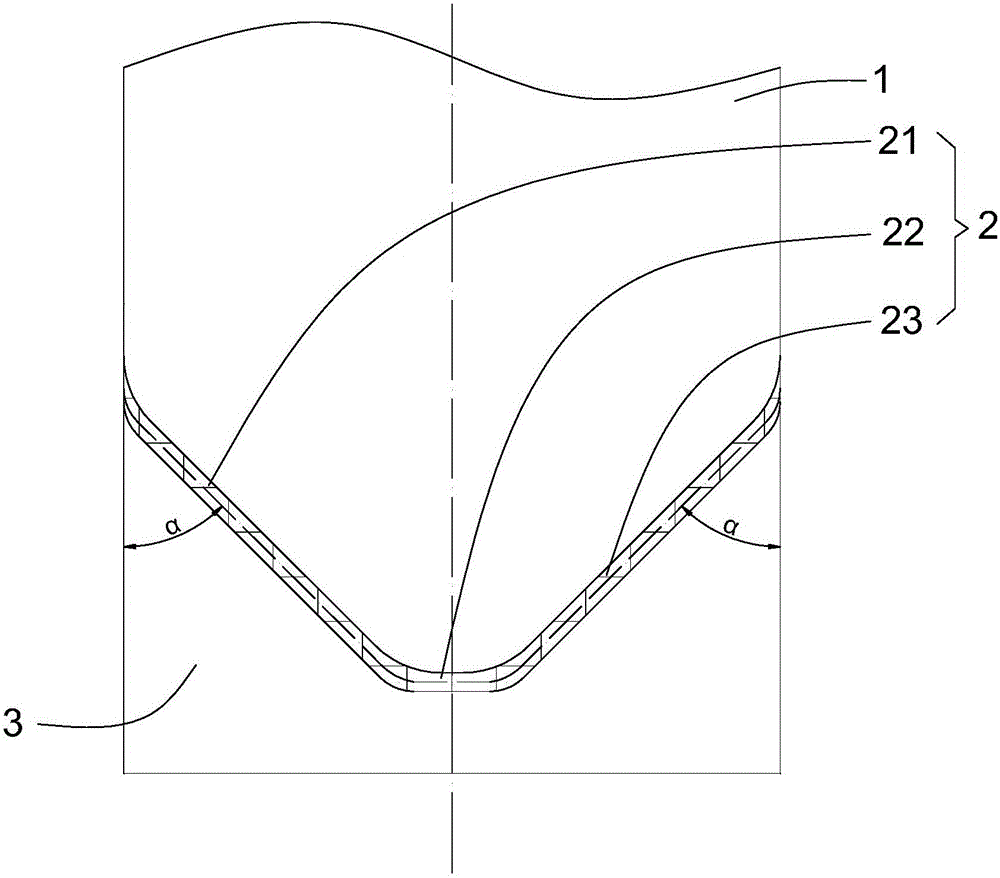

[0059] This embodiment is basically the same as the water medium energy conversion blasting method of Embodiment 1, and the water medium and explosives with a mass ratio greater than or equal to the optimal value M are also installed in the water medium energy conversion blasting charge chamber, and the explosives and water Media are isolated from each other. The main difference is that the charge cavity of the water medium energy-transforming blasting in this embodiment has a water blasting hole, and the explosive in the water blasting hole is installed in a waterproof bag to form a drug coil, and the drug coil is inserted into the water blasting hole. In the middle, the explosive and the water medium are isolated from each other, and a radially uncoupled charge structure is formed between the inner wall of the water blast hole and the charge coil, and the water medium in the water blast hole is located between the inner wall of the water blast hole and the charge coil .

[...

Embodiment 3

[0062] The water medium energy conversion blasting method of this embodiment is basically the same as that of Embodiment 2, and the water medium energy conversion blasting charge chamber in this embodiment is an underwater blast hole in a water blast hole, and the underwater blast hole is also the same. The water medium and the explosive whose mass ratio is greater than or equal to the optimal value M are installed, and the explosive is installed in a waterproof bag to form a charge roll, and the charge roll is inserted in the underwater blasthole so that the explosive and the water medium are isolated from each other. The method of isolating the explosive and the water medium in step 1) of the water medium energy-transforming blasting method in this embodiment is completely the same as that in Embodiment 2, so it will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com