Preparation method for nitrogen-containing activated carbon catalyst

A technology of activated carbon and catalyst, applied in the field of preparation of nitrogen-containing activated carbon catalyst, can solve the problems of lack of direct data to prove the existence and exact role of nitrogen-containing functional groups, lack of pertinence of high-nitrogen-containing activated carbon, waste of nitrogen-containing reagents, etc. The high temperature activation period is short, the cost is low, and the process is safe and controllable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

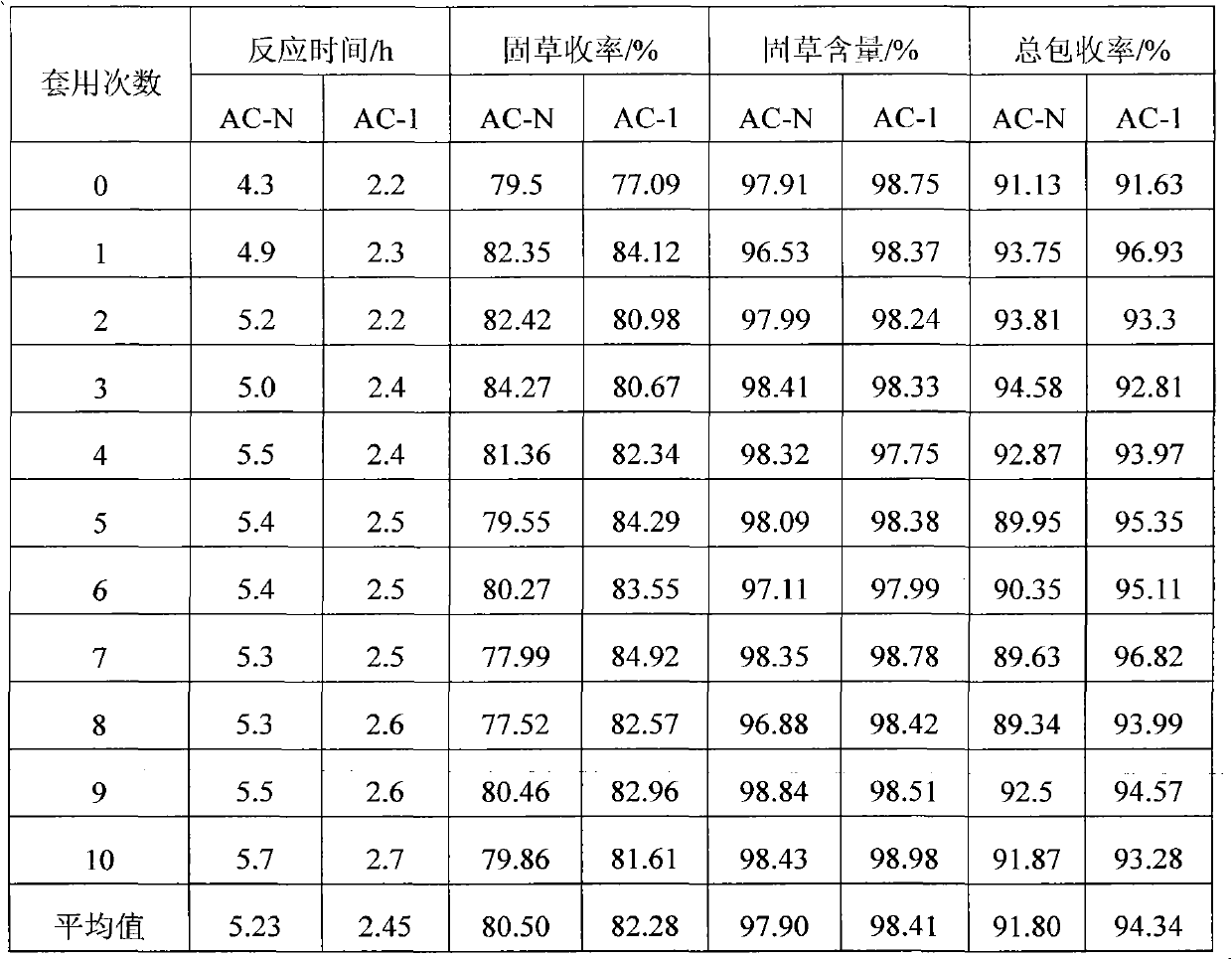

Examples

Embodiment 1

[0029] 1) Raw material pretreatment: with the coconut core carbonized material as raw material, the carbonized material used in the present invention comes from a certain activated carbon factory in Hebei. Atmospheric pressure, 60°C, with 68% HNO 3 Immerse the carbonized material at a volume ratio of 2:1 for 24 hours, filter to remove the impregnating solution, wash the residue with deionized water until neutral, and dry at 110°C to constant weight to obtain the treated carbonized material;

[0030] 2) Introduction of nitrogen-containing reagents: crush the dried carbonized material, sieve 100-200 meshes after crushing, mix nitrogen-containing reagent urea into a quartz boat at a molar ratio of N / C of 0.64;

[0031] 3) Activation: Continuous N at a flow rate of 10mL / min 2 Under protection, raise the temperature to 200°C and keep it warm for 2 hours; continue to raise the temperature to 700°C, keep it warm for 8 hours, then stop heating and drop to room temperature to get the ...

Embodiment 2-3

[0038] Respectively with hawthorn core (example 2), peach core (example 3) carbonized material as raw material, melamine is nitrogen-containing reagent, prepare nitrogen-containing activated carbon catalyst as follows:

[0039] 1) Raw material pretreatment: under normal pressure and 100°C, use 68% HNO 3 Reflux the carbonized material at a volume ratio of 2:1 for 4 hours, filter, wash the residue with deionized water until neutral, and dry at 110°C to constant weight to obtain the treated carbonized material;

[0040] The 2nd)-4) step operation is the same as embodiment 1. Catalyst number: AC-2 made from hawthorn kernel charred material, and catalyst number: AC-3 made from peach kernel charred material. Its elemental analysis test and reactivity test method are the same as in Example 1, and the test results are listed in Table 1.

Embodiment 4-5

[0042] In order to illustrate the nitrogen-containing carbon prepared when aniline used in the present invention is a nitrogen-containing reagent, this group of embodiments uses apricot stone (example 4) and coal powder (example 5) charring material as raw materials respectively, and aniline is a nitrogen-containing reagent, by following Steps to prepare nitrogen-containing activated carbon:

[0043] 1) Raw material pretreatment: use apricot kernels or pulverized coal carbonization materials as raw materials respectively, under normal pressure, at 80°C, use 68% HNO 3 Immerse the carbonized material at a volume ratio of 2:1 for 12 hours, filter, wash the residue with deionized water until neutral, and dry at 110°C to constant weight to obtain the treated carbonized material;

[0044] 2) Introduction of nitrogen-containing reagent: crush the dried carbonized material, sieve 100-200 meshes after crushing, mix nitrogen-containing reagent aniline with N / C ratio of 0.64, and put it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com