Polyurethane chemical grouting material and production method

A kind of polyurethane chemistry and polyurethane technology, which is applied in the direction of building insulation materials, building components, sea area engineering, etc., can solve the problems of high cost, loose signs, insufficient water content of water-soluble polyurethane, etc., and achieve the effect of simple construction and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

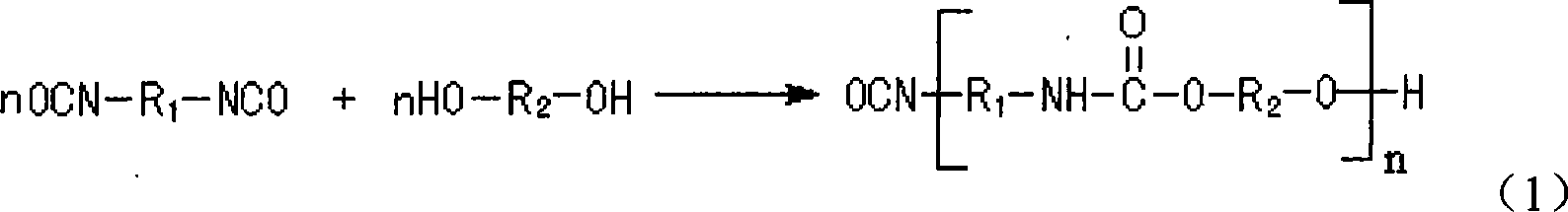

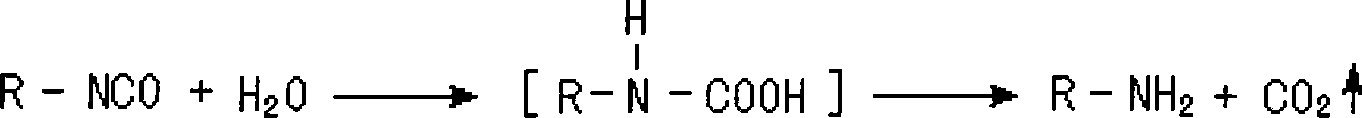

Method used

Image

Examples

Embodiment 1

[0057] (1) Preparation of hydroxyl-terminated polyurethane prepolymer

[0058] Pump 900 parts of hydrophilic polyether with a molecular weight of 1000 and a hydroxyl value of 168mg KOH / g into the reactor, and take samples to measure the moisture content by the Karl Fischer method. 2h until the moisture is qualified), start stirring, add accurately measured 111 parts of MDI, stir for 30min and then heat up, keep the constant temperature at 45°C for 1h, then continue to heat up to 80°C, and keep for 3.5h. Detect the -NCO content therein, and stop the reaction when there is almost no (indicating that the MDI is completely capped). Cool to room temperature (25°C), and keep sealed until use.

[0059] (2) Preparation of hydrophilic polyurethane prepolymer

[0060] Pump 480 parts of hydrophilic polyether with a molecular weight of 4000 and a hydroxyl value of 42 mg KOH / g into the reactor, and use Karl’s law to determine the water content. 2h until the moisture is qualified), add 2...

Embodiment 2

[0064] (1) Preparation of hydroxyl-terminated polyurethane prepolymer

[0065] Pump 800 parts of hydrophilic polyether with a molecular weight of 1000 and a hydroxyl value of 168mg KOH / g into the reactor, and take samples to measure the moisture content by the Karl Fischer method. 2h until the moisture is qualified), start stirring, add 99 parts of MDI accurately measured, stir for 30min and then heat up, keep the constant temperature at 50°C for 1h, then continue to heat up to 85°C, and keep for 4.0h. Detect the -NCO content therein, and stop the reaction when there is almost no (indicating that the MDI is completely capped). Cool to room temperature (25°C), and keep sealed until use.

[0066] (2) Preparation of hydrophilic polyurethane prepolymer

[0067] Pump 450 parts of hydrophilic polyether with a molecular weight of 4000 and a hydroxyl value of 42 mg KOH / g into the reactor, and use Karl’s law to determine the water content. 2h until the moisture is qualified), add 24...

Embodiment 3

[0071] (1) Preparation of hydroxyl-terminated polyurethane prepolymer

[0072] Pump 812 parts of polyethylene glycol with a molecular weight of 400 into the reaction kettle, start stirring at room temperature and add 250 parts of MDI accurately measured, and heat up after stirring for 30 minutes. Keep the constant temperature at 48°C for 1h, then continue to raise the temperature to 82°C, keep it for 3.75h, detect the -NCO content in it, and stop the reaction when there is almost no (at this time MDI is completely blocked). Cool to room temperature (25°C), and keep sealed until use.

[0073] (2) Preparation of hydrophilic polyurethane prepolymer

[0074] Pump 550 parts of hydrophilic polyether with a molecular weight of 3500 and a hydroxyl value of 51 mg KOH / g into the reactor, and take samples to measure the moisture content using Karl's law. 2h until the moisture is qualified), add 198 parts of the hydroxyl-terminated prepolymer prepared by the above reaction, and stir eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com