Method for grouting sealing of gap between steel door frame of protective sealed door and wall

A technology of steel door frame and airtight door is applied in the field of grouting and sealing the gap between the steel door frame and the wall of the protective airtight door. Achieve significant social and economic benefits, smooth surface and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

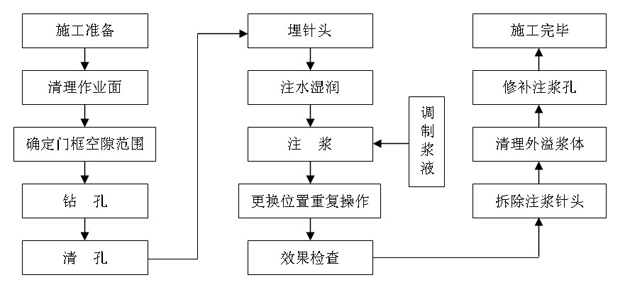

[0039] A grouting sealing method for the gap between the steel door frame and the wall of a protective airtight door, comprising the following process:

[0040] 1. Construction preparation

[0041] Prepare all kinds of machines, tools and materials, be familiar with the construction process, and master the characteristics of materials.

[0042] 2. Clean up the work surface

[0043] Clean up the sundries around the door frame to be repaired.

[0044] 3. Determine the door frame clearance range

[0045] Lightly tap the door frame or the joint between the door frame and the wall with a small hammer, mark the range of the gap with chalk, and determine the number of injection points according to the length of the gap.

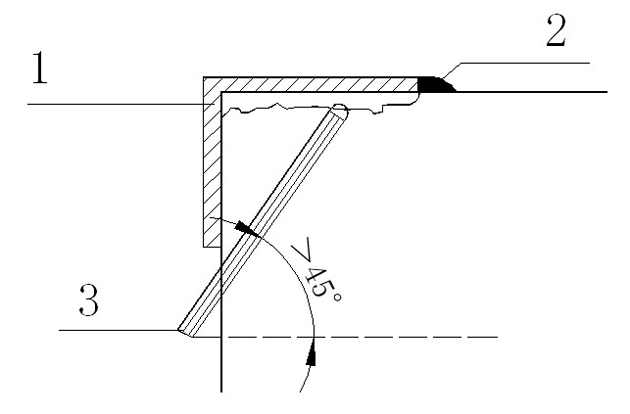

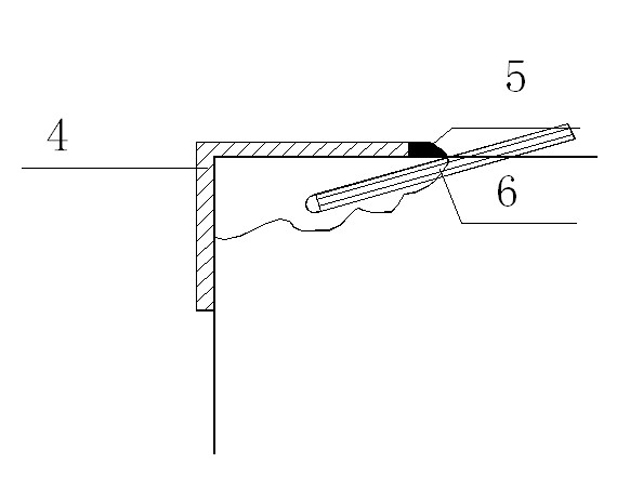

[0046] 4. Drilling, Clearing

[0047] Drill holes on the concrete surface near the gap, and drill holes obliquely upward or downward in the direction of the gap according to the size of the gap. The hole distance should be determined according to the actual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com