Wall body structure seepage treatment method

A technology of wall structure and treatment method, applied in building construction, building maintenance, construction and other directions, can solve the problems of easy cracking, quality control, poor technical control, and poor vibration, so as to prolong the service life. , good waterproof effect, strong permeability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

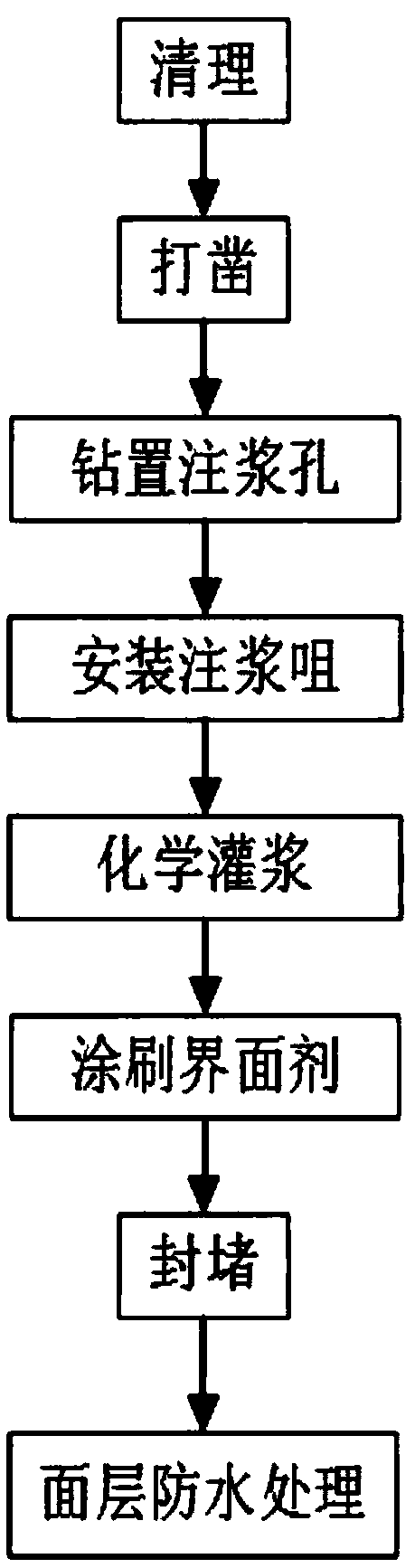

[0052] Such as Figure 1 to Figure 22 Shown, a kind of wall structure seepage treatment method, this method comprises the following steps:

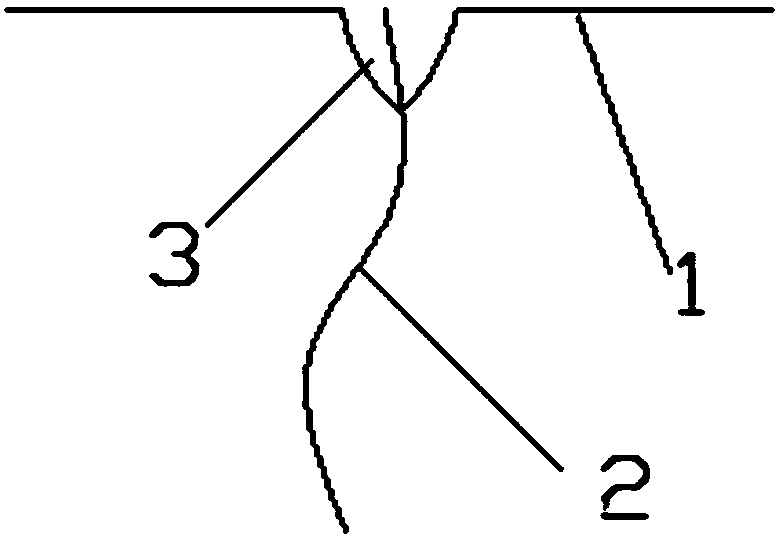

[0053] S1. Cleaning: Clean up the calcium carbonate and residual dust on the structural base surface of the wall body 1 to expose the leaking part 2;

[0054] S2. Drilling: taking the leaking part 2 as the center point, digging around the leaking part 2;

[0055] S3. Drilling the grouting hole: find the water flow direction of the leakage part 2, and drill the grouting hole 4 in the direction where the inclination angle of the water flow direction of the leakage part 2 is 30°-60°;

[0056] S4. Install the grouting nozzle: Use a suction blower with a voltage and frequency of 220V-50Hz and an air volume of 2.5m3 / min to connect a Φ12mm rubber hose to blow and suck the residual dust in the grouting hole 4. Acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com