Grouting combined prestressed anchor rod static pressure pile rectification and reinforcement method

An anchor static pressure pile and prestressing technology, applied in the field of correction and reinforcement, can solve the problems of long time, high load requirements, unsatisfactory correction effect, etc., and achieve the effect of small quantity, technical feasibility and short consolidation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

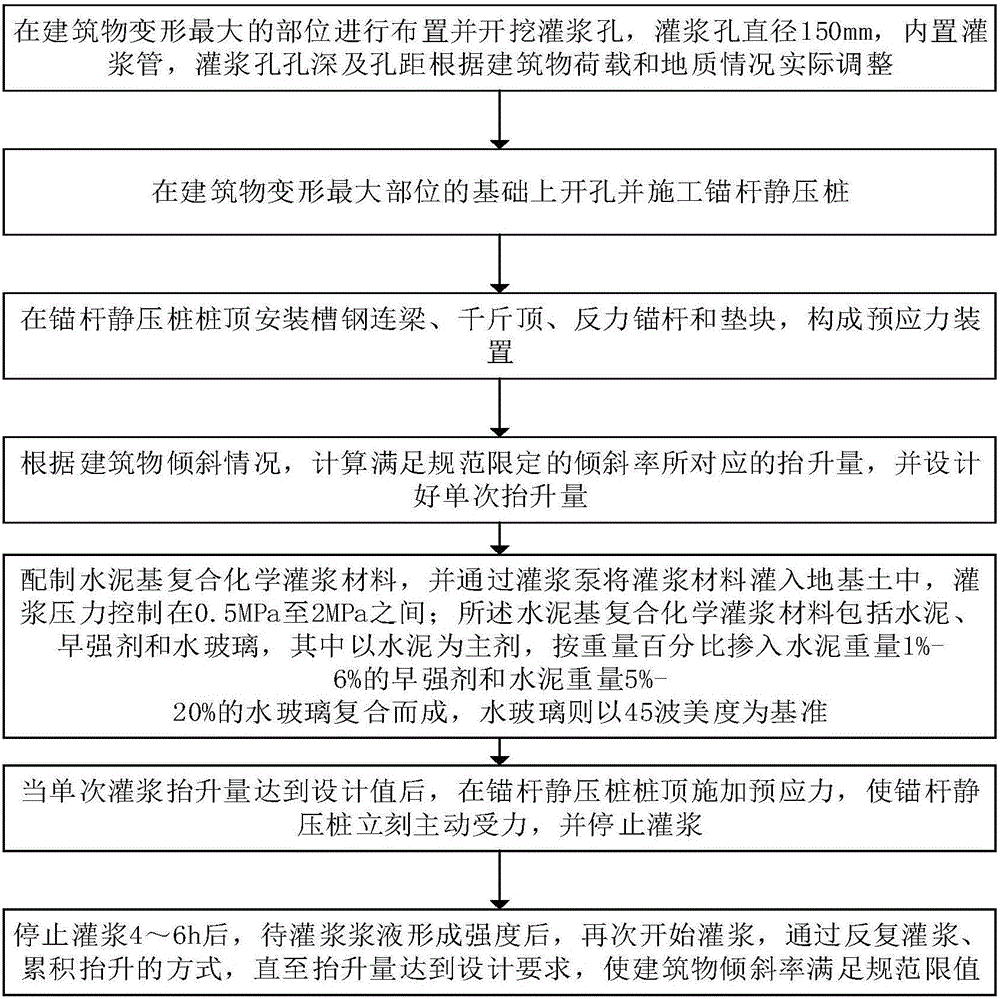

[0039] Such as figure 1 As shown, the present invention discloses a deflection correction and strengthening method for grouting combined with prestressed anchor static pressure piles. Pile 1.

[0040] Grouting lifts the building using a special cement-based composite chemical grouting material, which is poured into the foundation soil through the grouting pipe to form excess pore pressure in the foundation soil. Due to the three-dimensional stress state of the soil, the foundation soil will deform upwards, and the building Under the action of the excess pore pressure of the foundation soil, it also rises upwards. The special cement-based composite chemical grouting material can be solidified in about 15s, and has a certain degree of expansion, which is beneficial to lift the building, but the time for the consolidated body to form strength is about 4h to 6h, and the time for the consolidated body to form strength Before, once the grouting is stopped, the excess pore pressure...

Embodiment 2

[0057] Such as Figure 1 to Figure 4 As shown, the specific implementation process of the deviation correction reinforcement method provided by the present invention is as follows:

[0058] 1. Construction preparation

[0059] 1) Before construction, the location of the largest settlement and the direction of inclination should be determined according to the building deformation appraisal report, and the best location for chemical grouting and anchor static pressure pile 1 should be determined. Pile placement and grouting at the position where the settlement is large and the settlement deformation rate is the largest can achieve the effect of four or two.

[0060] 2) Before construction, pay attention to investigate the pipeline conditions around the building, and take protective measures to avoid pipeline damage or blockage caused by grouting during grouting.

[0061] 2. Construction of anchor static pressure pile 1

[0062] 1) Holes are drilled around the foundation of th...

Embodiment 3

[0075] Regarding the cement-based composite chemical grouting material provided by the present invention, the grouting material mainly includes cement, early-strength agent and water glass; wherein the main agent is cement, and the early-strength agent and cement of 1% of the cement weight are mixed in by weight percentage 20% of the weight of water glass is compounded, and the water glass is based on 45 Baume degrees, that is, when 1 ton of cement is used, 10kg of early strength agent and 200kg of water glass need to be mixed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Carrying capacity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com