Draught fan foundation strengthening method

A fan foundation and foundation ring technology, which is applied in foundation structure engineering, foundation structure repair, construction, etc., can solve the problems of epoxy mortar curing time and long maintenance period, economic loss of fan shutdown, cumbersome connection and coordination, etc., and achieve reduction The effects of on-site downtime, shortened construction period, and short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

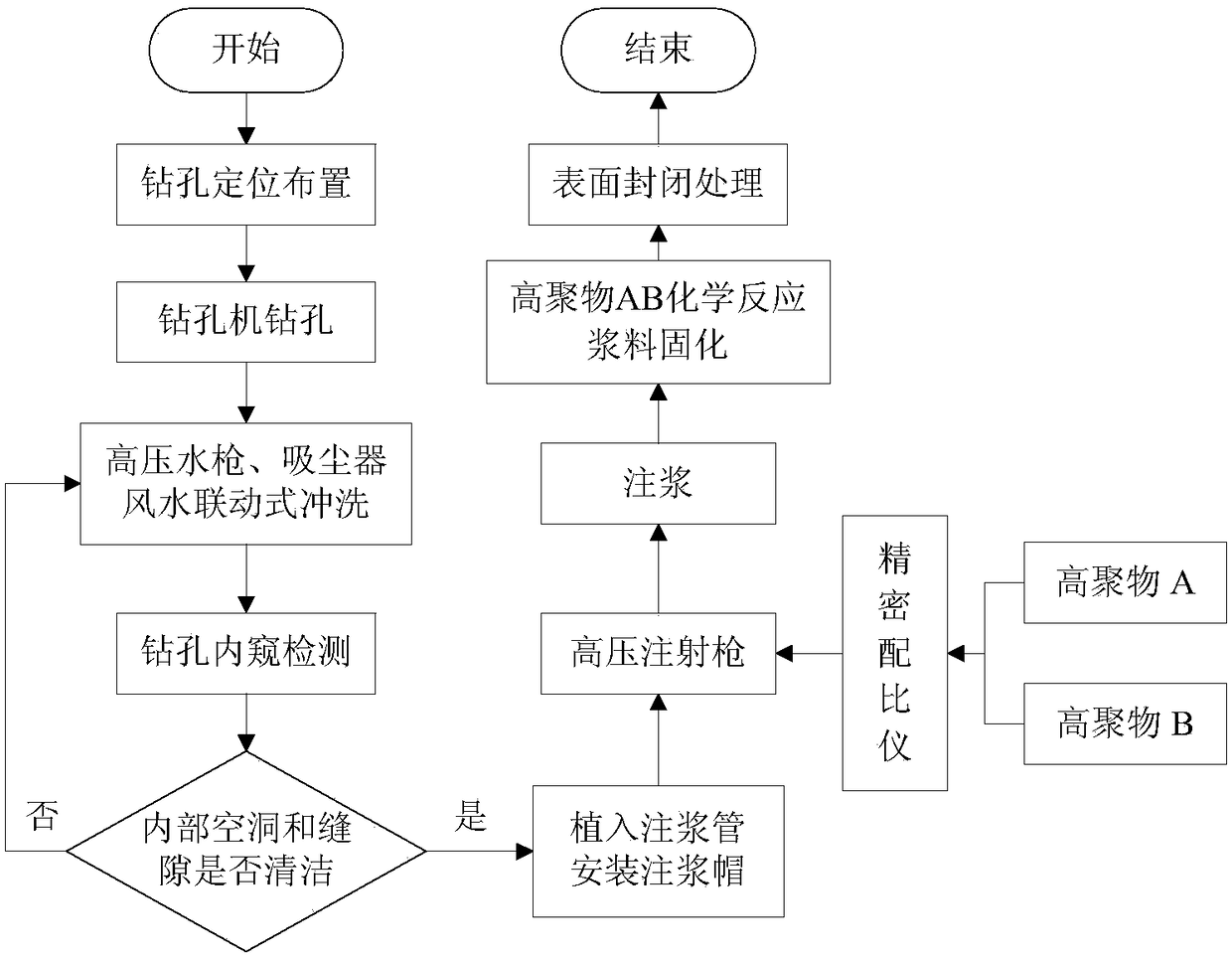

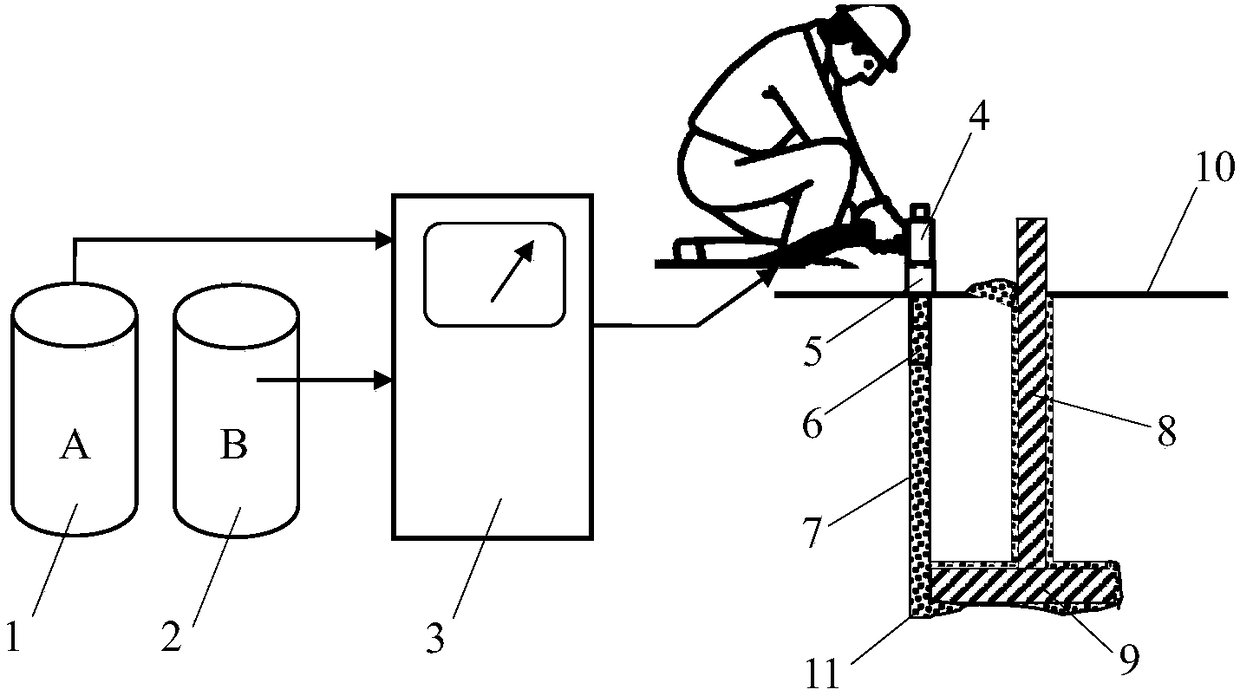

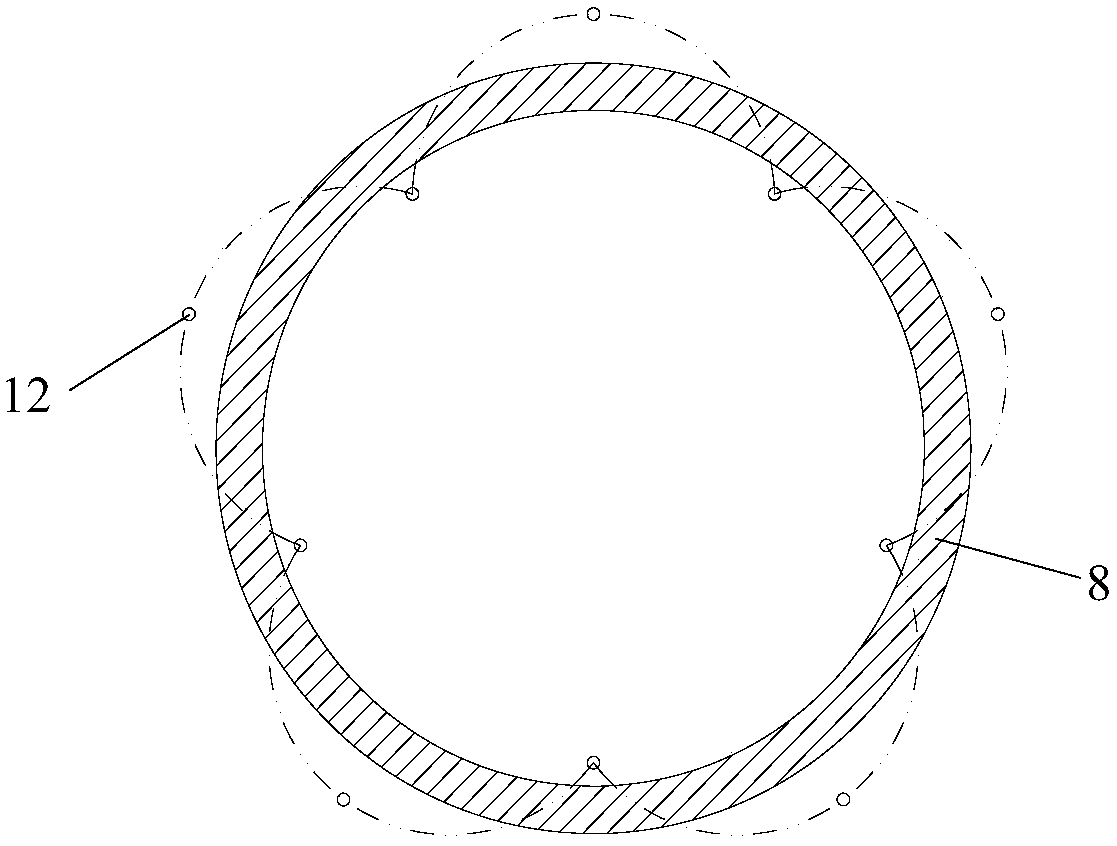

[0028] Such as Figure 1~Figure 3 As shown, the method for strengthening the foundation of the fan first needs to arrange the holes. As a preferred solution, in this embodiment, 10 holes 12 are evenly arranged in a quincunx circular direction at 100mm positions inside and outside the base ring 8, using drilling holes. Machine drill to the bottom surface of the base ring bottom flange 9 at 100mm with a diameter of 32mm.

[0029] After the drilling channel 7 is formed, the fine particles in the hole and the surrounding space are washed clean. The washing process is first washed with a large flow of high-pressure water flow, the washing pressure is 1MPa, the flow rate is greater than 60L / min, until the return water becomes clear; then switch to pulsation The flushing mode continues flushing for 30 minutes. Drilling and flushing has a greater impact on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Drilling aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com