Water seepage plugging construction method of shaft construction seams under high water head

A construction method and technology of construction joints, which are applied in water conservancy projects, sea area projects, infrastructure projects, etc., can solve the problems of frequent recharge, the inability to lower the external water level, and affect the normal operation of water conservancy projects, etc., and achieve the goal of improving project efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

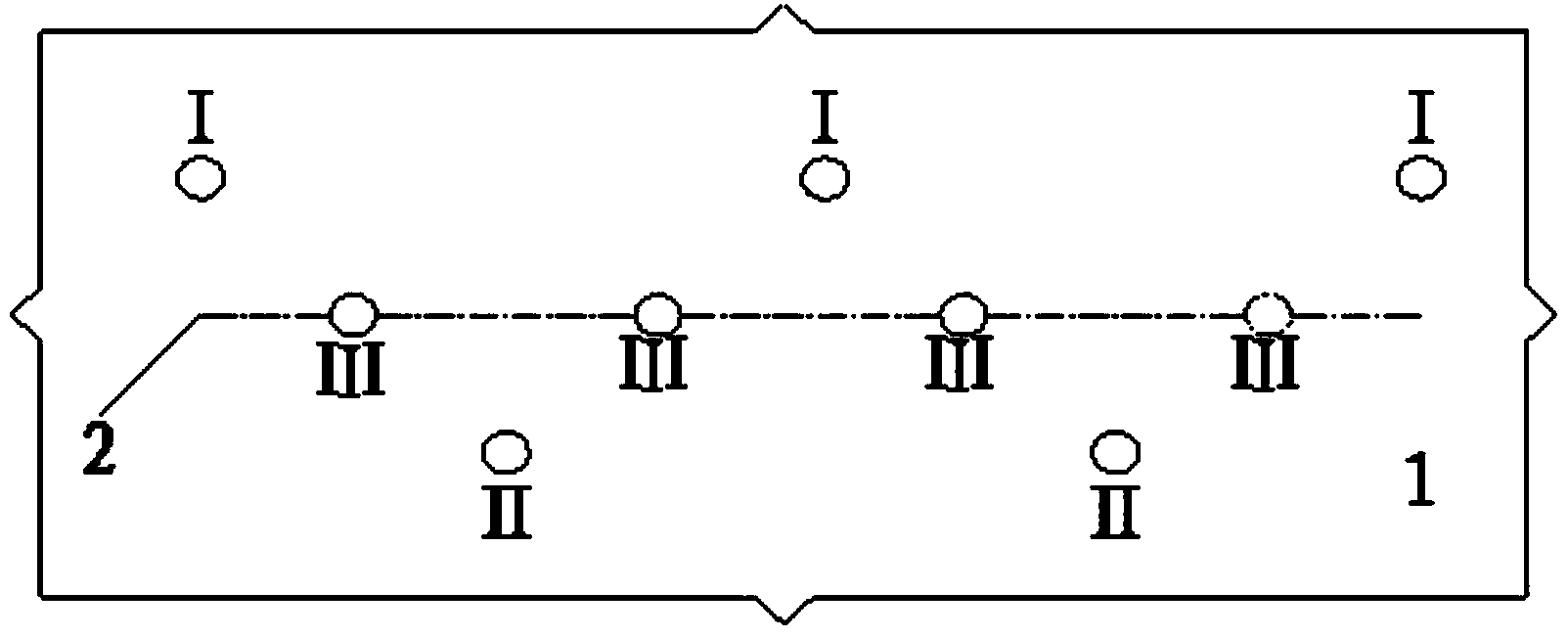

[0034] Below in conjunction with accompanying drawing and specific embodiment, the scheme of the present invention is described in further detail:

[0035] A construction method for water seepage and leakage plugging of vertical shaft construction joints under high water head, the specific steps are as follows:

[0036] Step 1: Selection of grouting material: water-soluble polyurethane chemical grouting material is selected as the crack filling material;

[0037] Step 2: Open water treatment: before grouting, use fibrous materials to block the leaking joints to create a safe construction environment and prevent chemical materials from leaking out;

[0038] Step 3: Drilling: Arrange the drilling position 5-10cm above the gap. The drilling is drilled with an electric drill and an alloy drill bit. The drilling diameter is 14mm; ensure that the water stop needle with a diameter of 10mm can be put in for extrusion and expansion;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com