Chemical grouting filling seal material for coal mine, and preparation method and application method thereof

A grouting filling material and chemical technology, applied in the field of chemical materials, can solve the problems of high monomer content of urea-formaldehyde resin raw materials, low foaming ratio, and environmental pollution, and achieve easy control of product quality, good flame retardant and antistatic properties, The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

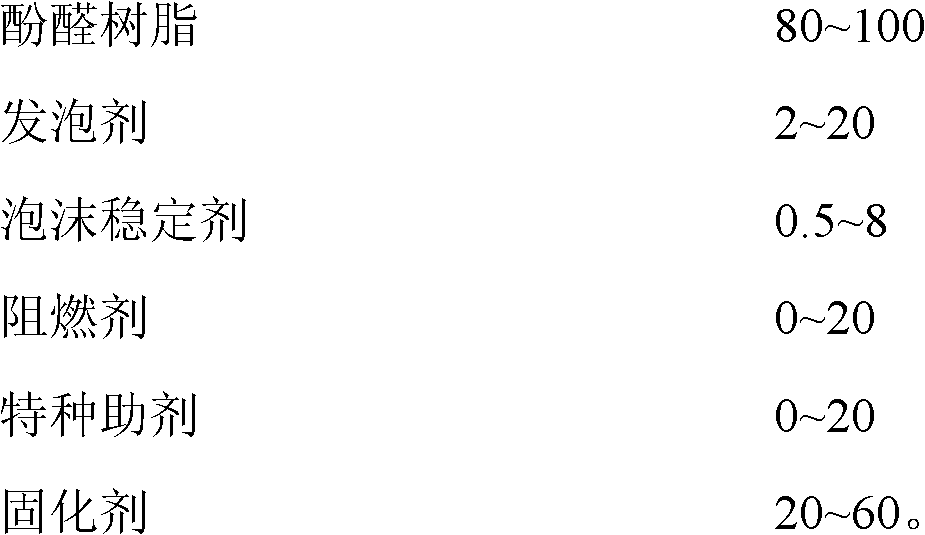

[0031] A component

[0032]

[0033] B component

[0034] Hardener 1 65

[0035] Hardener 2 15

[0036] Hardener 3 20

[0037] Among them, the phenolic resin is phenol formaldehyde resin, the foaming agent is azobisisobutylcyanide, the foam stabilizer is anionic surfactant, and the special additive is a mixture of Hemmings Dechem 903, 201 and polyester polyol.

[0038] Wherein, curing agent 1 is benzoic acid, curing agent 2 is p-hydroxybenzenesulfonic acid, and curing agent 3 is phosphoric acid.

[0039] Among them, the preparation process steps of component A:

[0040] 1) According to the ratio, take part of the phenolic resin and add it to the pull tank, start stirring, add additives, after stirring for 2 hours, add foaming agent, and disperse at high speed for 30 minutes to obtain a pre-dispersed slurry.

[0041] 2) Add the remaining phenolic resin into the reaction kettle, start stirring, add the pre-dispersed slurry obtained in 1, stir for 1 hour, then add foam st...

Embodiment 2

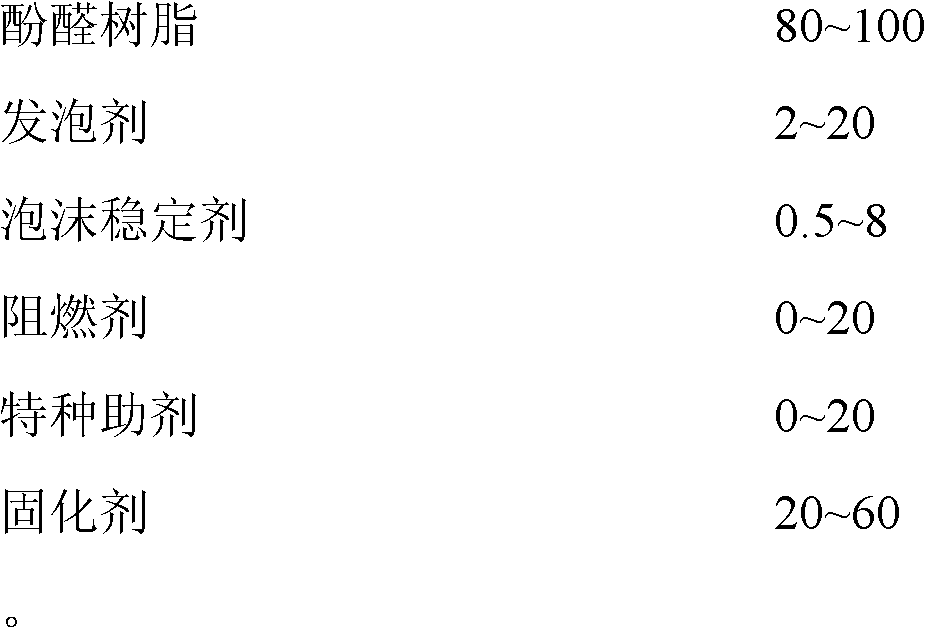

[0047] A component:

[0048]

[0049] B component

[0050] Hardener 1 65

[0051] Hardener 2 15

[0052] Hardener 3 20

[0053] Among them, the phenolic resin is cresol acetaldehyde resin, the foaming agent is sodium carbonate, the foam stabilizer is nonionic surfactant, and the special additive is a mixture of Hemmings Dechem 912, 908 and polyether polyol.

[0054] Wherein, the curing agent 1 is p-hydroxybenzenesulfonic acid, the curing agent 2 is acetic acid, and the curing agent 3 is sulfuric acid. When in use, the A and B components are grouted with a professional grouting pump, and they can be foamed at room temperature to obtain a filling material with a high foaming ratio.

Embodiment 3

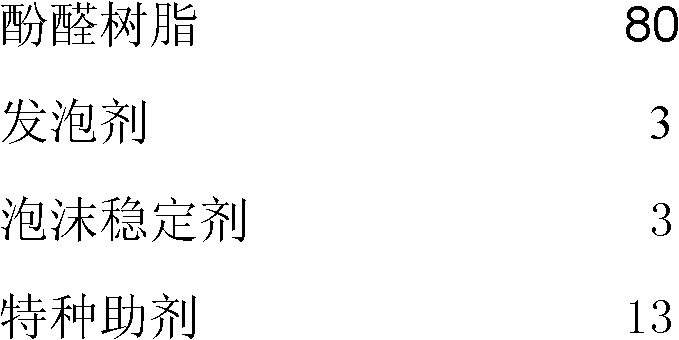

[0056] A component:

[0057]

[0058] B component

[0059] Hardener 1 55

[0060] Hardener 2 25

[0061] Hardener 3 20

[0062] Among them, the phenolic resin is phenol paraformaldehyde resin, the foaming agent is a mixture of sodium carbonate and azobisisobutylcyanide, the foam stabilizer is cationic surfactant, and the special additives are Hemings Dechem 923, 275, poly The mixture of vinyl alcohol and flame retardant is triphenyl phosphate.

[0063] Wherein, curing agent 1 is o-hydroxybenzenesulfonic acid, curing agent 2 is benzoic acid, and curing agent 3 is sulfuric acid.

[0064] When in use, the A and B components are grouted with a professional grouting pump, and they can be foamed at room temperature to obtain a high flame-retardant filling material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com