Water-rich loose and broken coal and rock mass grouting solidification experimental device and effect evaluation method

A technology for crushing coal and rock mass and experimental device, applied in mining devices, earthwork drilling, mining equipment, etc., can solve the complex engineering geological structure, the grouting reinforcement construction technology relies on traditional experience, and the difficulty of grouting effect detection and evaluation, etc. problem, to achieve the effect of excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation on the invention.

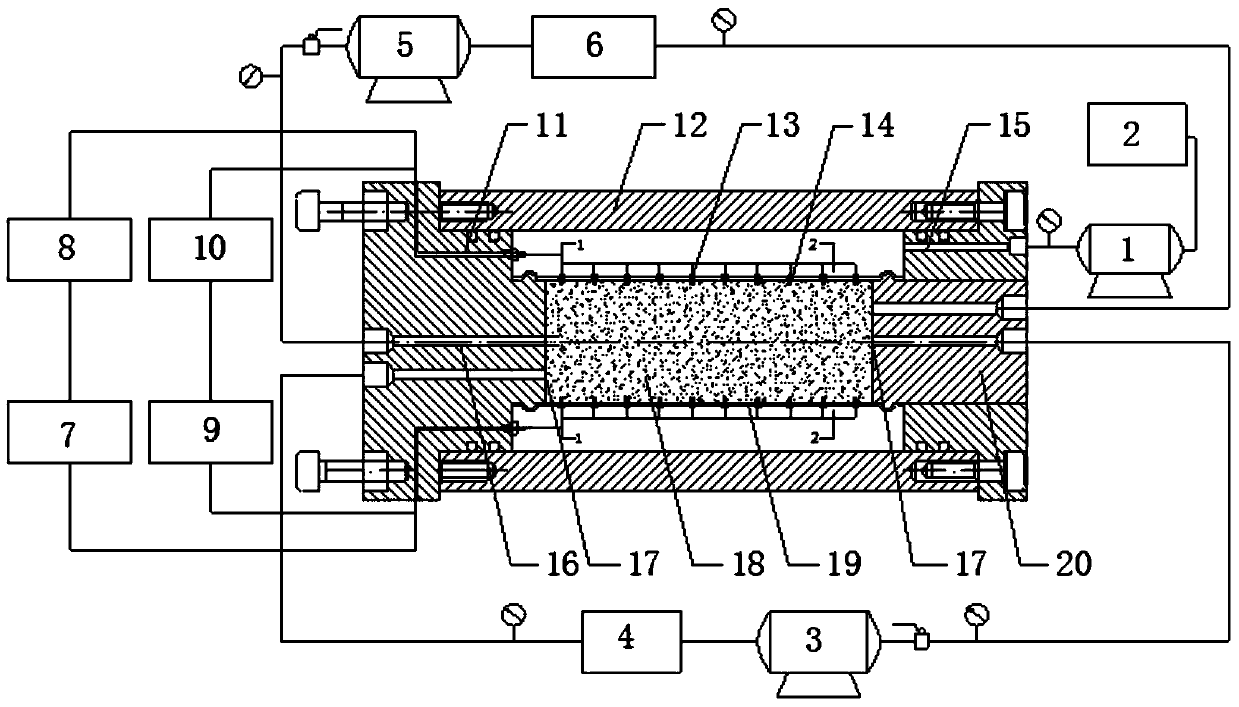

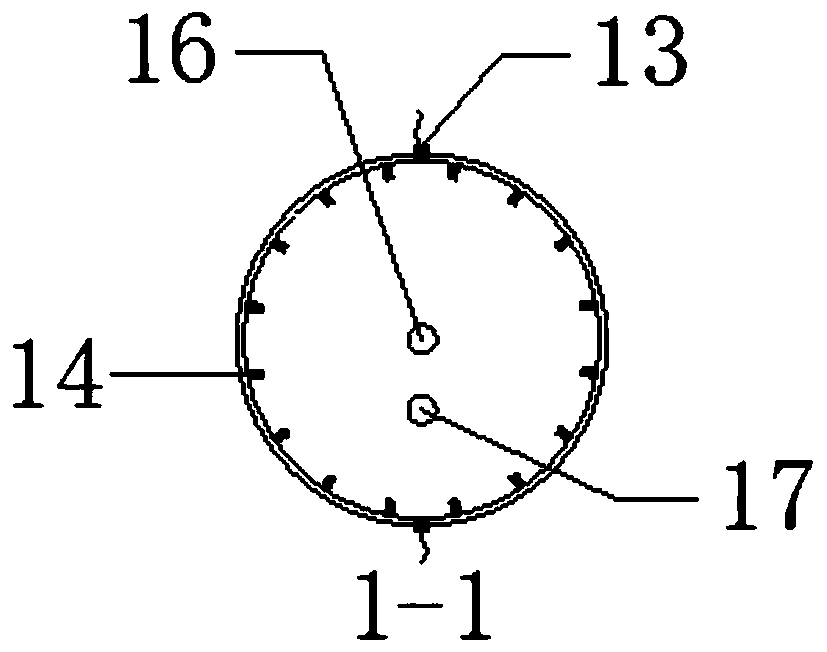

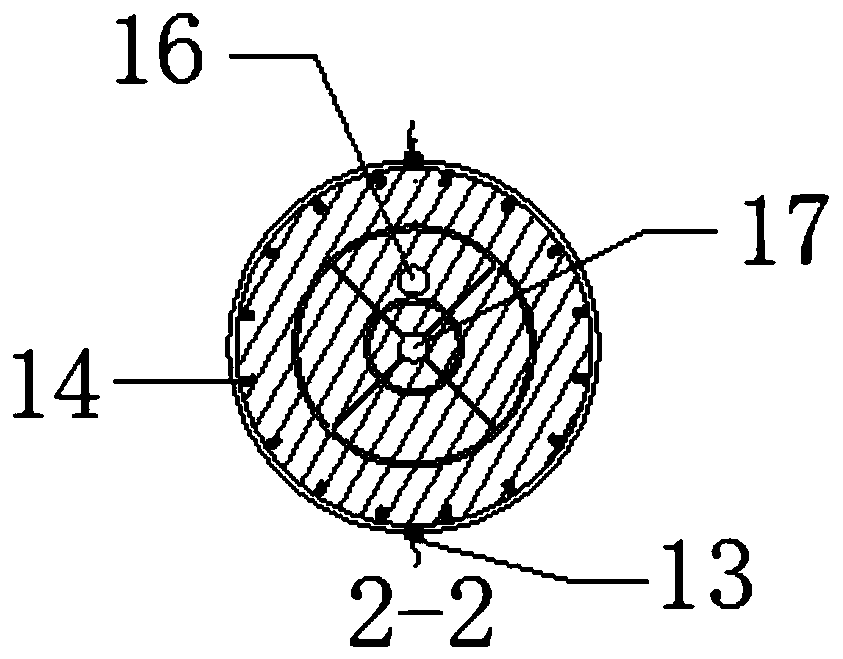

[0032] Such as figure 1 As shown, the water-rich loose broken coal and rock mass grouting consolidation experiment device of the present invention includes a steel structure still body 12, an experimental cavity 18 that is arranged inside the steel structure still body 12 and loaded by a confining pressure loading system, A circulating water pressure loading system connected to the confining pressure loading system, and a grouting system, ultrasonic testing and resistivity tomography system connected to the confining pressure loading system.

[0033] Among them, the confining pressure loading system includes a pair of pressure heads 20, and the steel structure kettle body 12 and the experimental cavity 18 are clamped in the pressure heads 20 by bolts. Confining pressure pipeline 15, g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com