High-strength high-fire-retardant low-heat-release mining polyurethane grouting reinforcement material and preparation method and application thereof

A technology of grouting reinforcement and high flame retardancy, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of high expansion pressure, temperature rise, poor flame retardancy, etc., to reduce foaming and expansion, improve Effect of improving compressive strength and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Preparation of component A

[0042] In a closed reactor, first add 25.0 g of bisphenol F type epoxy resin 830S, and then add 475.0 g of diphenylmethane diisocyanate (MDI-50), and stir for 0.5 to 1.0 h to obtain 500.0 g of component A.

[0043] (2) Preparation of component B

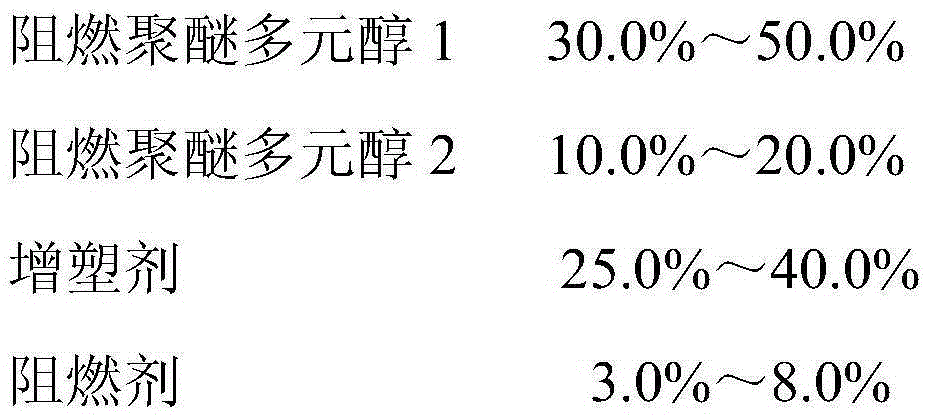

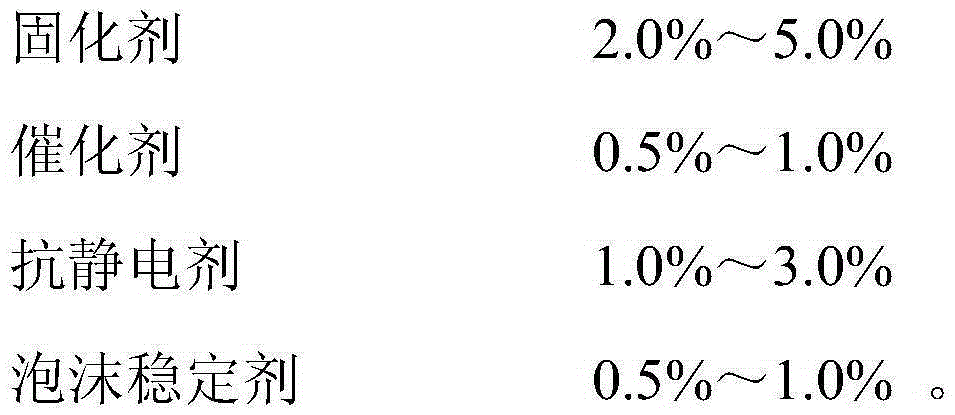

[0044] In a closed reactor, add 500.0g flame-retardant polyether polyol PuranolRF3774 (Jiahua Chemical Co., Ltd.), 100.0g flame-retardant polyether polyol PuranolRF3776 (Jiahua Chemical Co., Ltd.), and 250.0g plasticizer chlorine. Fossil wax-42, 80.0g flame retardant FR-310, 20.0g curing agent DMP-30, catalyst 10.0g (of which dibutyltin dilaurate (DBTDL) 5.0g, A-335.0g), 30.0g antistatic agent JA -10ql, 10.0g foam stabilizer SD-502, stir for 2.0~3.0h, obtain 1000.0g component B.

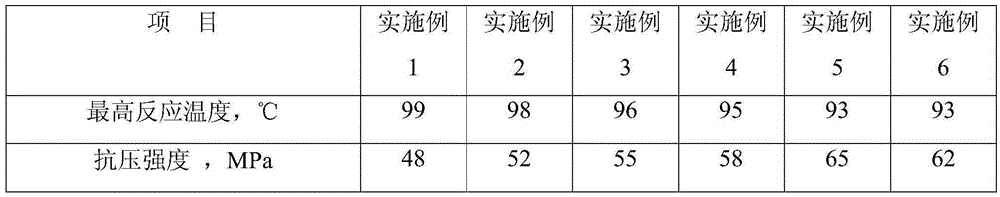

[0045] (3) Mix components A and B uniformly according to a volume ratio of 1:1 to obtain a polyurethane grouting reinforcement material for mines with high strength, high flame resistance and low exotherm. Under standard co...

Embodiment 2

[0047] (1) Preparation of component A

[0048] In a closed reactor, first add 50.0 g of bisphenol F epoxy resin 830S, and then add 450.0 g of diphenylmethane diisocyanate (MDI-50), and stir for 0.5 to 1.0 h to obtain 500.0 g of component A.

[0049] (2) Preparation of component B

[0050] In a closed reactor, add 460.0g flame-retardant polyether polyol PuranolRF3774 (Jiahua Chemical Co., Ltd.), 120.0g flame-retardant polyether polyol PuranolRF3776 (Jiahua Chemical Co., Ltd.), and 280.0g plasticizer chlorine. Fossil wax-42, 65.0g flame retardant FR-310, 25.0g curing agent DMP-30, catalyst 10.0g (of which dibutyltin dilaurate (DBTDL) 5.0g, A-335.0g), 30.0g antistatic agent JA -10ql, 10.0g foam stabilizer SD-502, stir for 2.0~3.0h, obtain 1000.0g component B.

[0051] (3) Mix components A and B uniformly according to a volume ratio of 1:1 to obtain a polyurethane grouting reinforcement material for mines with high strength, high flame resistance and low exotherm. Under standard conditi...

Embodiment 3

[0053] (1) Preparation of component A

[0054] In a closed reactor, first add 75.0 g of bisphenol F epoxy resin 830S, and then add 425.0 g of diphenylmethane diisocyanate (MDI-50), and stir for 0.5-1.0 h to obtain 500.0 g of component A.

[0055] (2) Preparation of component B

[0056] In a closed reactor, add 430.0g flame-retardant polyether polyol PuranolRF3774 (Jiahua Chemical Co., Ltd.), 140.0g flame-retardant polyether polyol PuranolRF3776 (Jiahua Chemical Co., Ltd.), and 310.0g plasticizer chlorine. Fossil wax-42, 50.0g flame retardant FR-310, 30.0g curing agent DMP-30, catalyst 7.5g (of which dibutyltin dilaurate (DBTDL) 5.0g, A-332.5g), 25.0g antistatic agent JA -10ql, 7.5g foam stabilizer SD-502, stir for 2.0-3.0h to obtain 1000.0g component B.

[0057] (3) Mix components A and B uniformly according to a volume ratio of 1:1 to obtain a polyurethane grouting reinforcement material for mines with high strength, high flame resistance and low exotherm. Under standard conditions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com