Method and device for repairing concrete gap with chemical grout

A technology of chemical grouting and concrete, applied in packaging, building maintenance, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

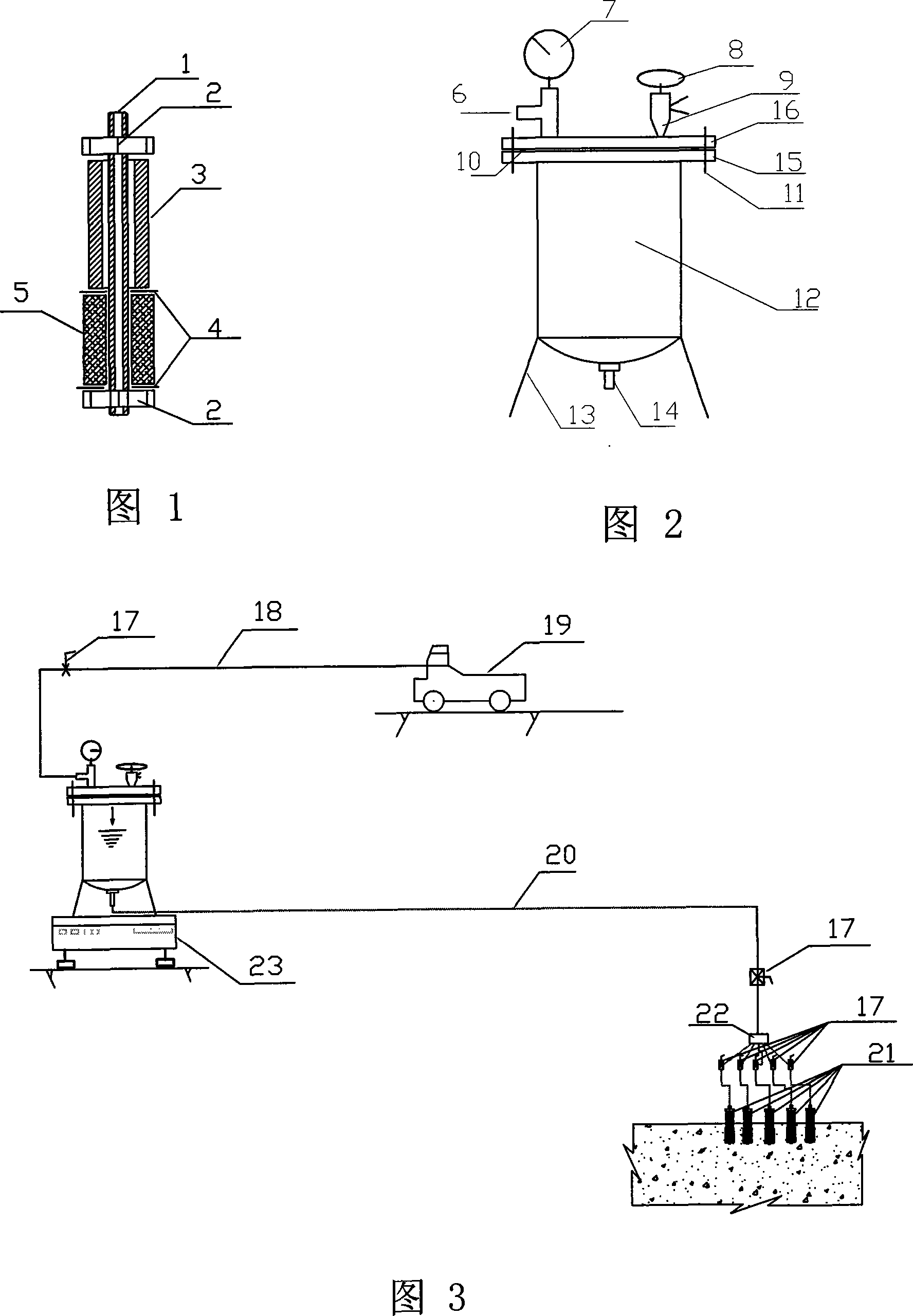

[0023] 1. Drilling: Before chemical grouting, according to the condition of the crack, the grouting hole must be drilled within 10cm to 15cm of the side of the crack or through the seam. The diameter of the drill hole is φ18mm; the depth of the drill hole is 10cm to 150cm. Due to the small diameter of the drilled hole, the secondary damage to the concrete caused by the drilled hole is effectively solved. The drilling spacing is: side holes of cracks: 10cm to 15cm away from the sides of cracks, hole spacing of 20cm to 35cm, drilling obliquely through cracks, according to the depth of cracks, more than two rows of drilling holes can be arranged, and each row of drilling holes is single The range of the cracks controlled by the hole is generally φ50cm~φ100cm in diameter; drilling through cracks: the spacing is 20cm~35cm. When the drilling depth exceeds 40cm, a threaded steel bar with a length of 60% to 80% of the drilling depth and a diameter of φ14mm to φ16mm is added in the dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com