Concrete integral production system

A production system, concrete technology, applied in the direction of clay preparation device, mixing operation control, chemical instruments and methods, etc., can solve the problems of concrete waste, large concrete slump loss, structural cold joints, etc., to avoid slump Loss, strengthen the dispersion effect, and ensure the effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

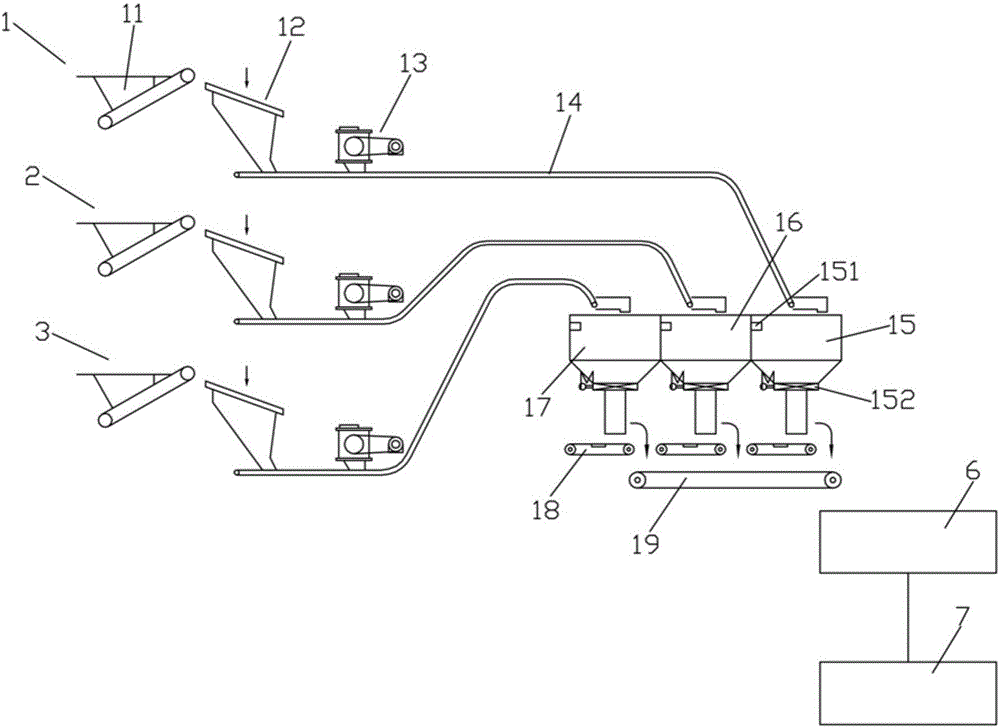

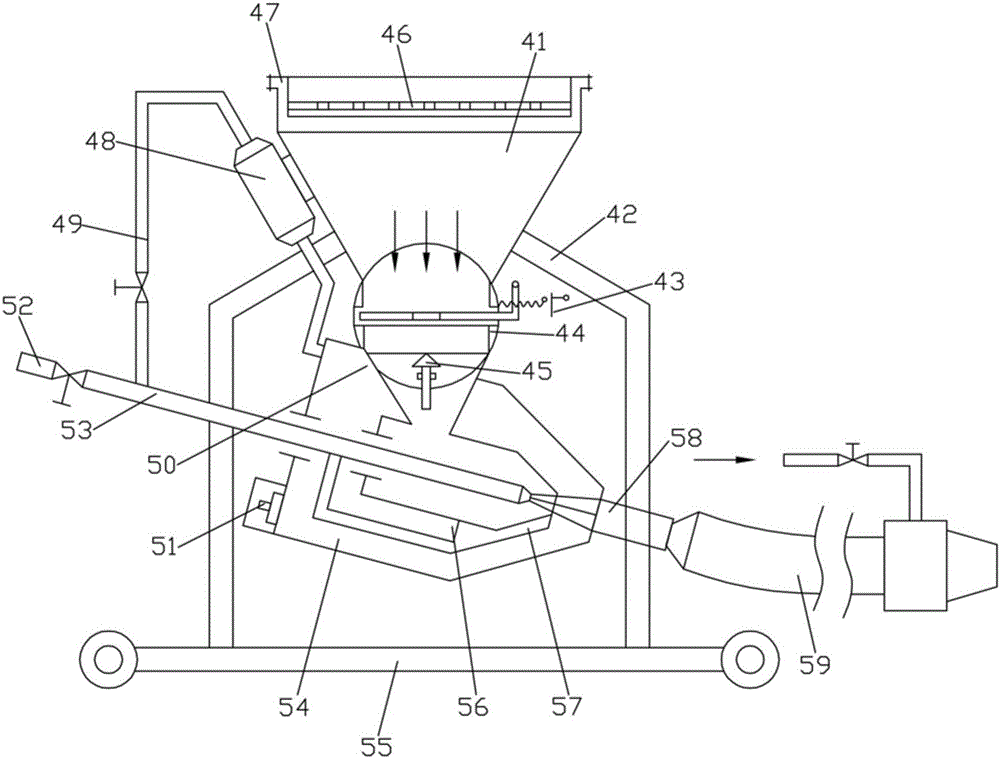

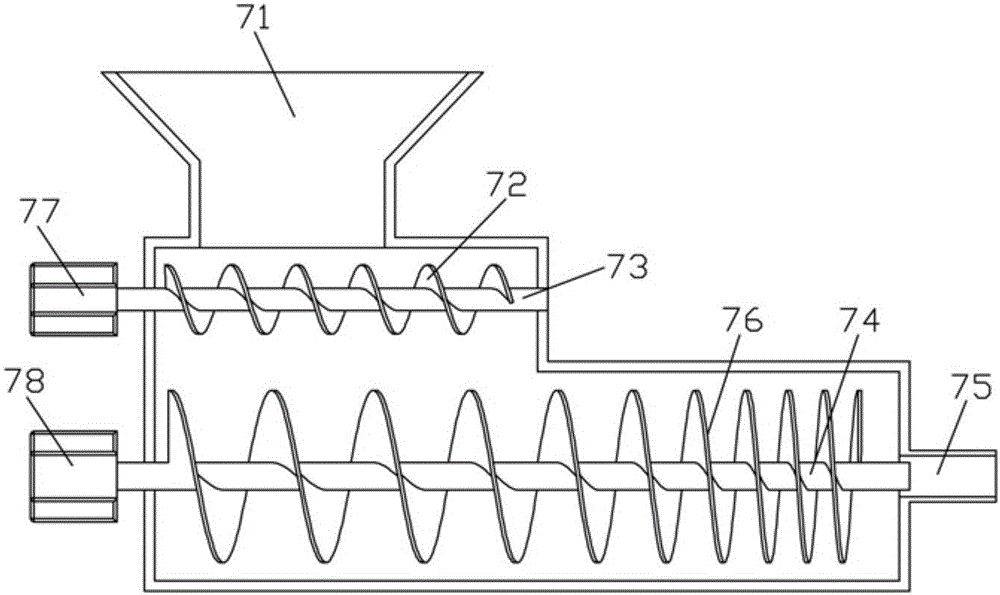

[0018] Such as Figure 1-2 As shown, the concrete integrated production system includes a dry material feeding device, a concrete mixing device 6, a screw extrusion conveying device 7 and a control device, and the dry material feeding device, the concrete mixing device 6, and the screw extruding conveying device 7 are arranged sequentially , wherein, the dry material feeding device includes cement conveying line 1, sand material conveying line 2 and crushed stone conveying line 3, cement, sand material and crushed stone enter the conveyor belt conveyor 19 after being pneumatically conveyed by the dry material feeding device, and Transported to the concrete mixing device 6 by the conveyor belt conveyor 19; the concrete mixing device 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com