Pulling-out method of underground piles by sleeving, vibrating and punching

A pile casing and casing technology, applied in the field of infrastructure construction, can solve problems that affect construction, cannot be removed, and verticality deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

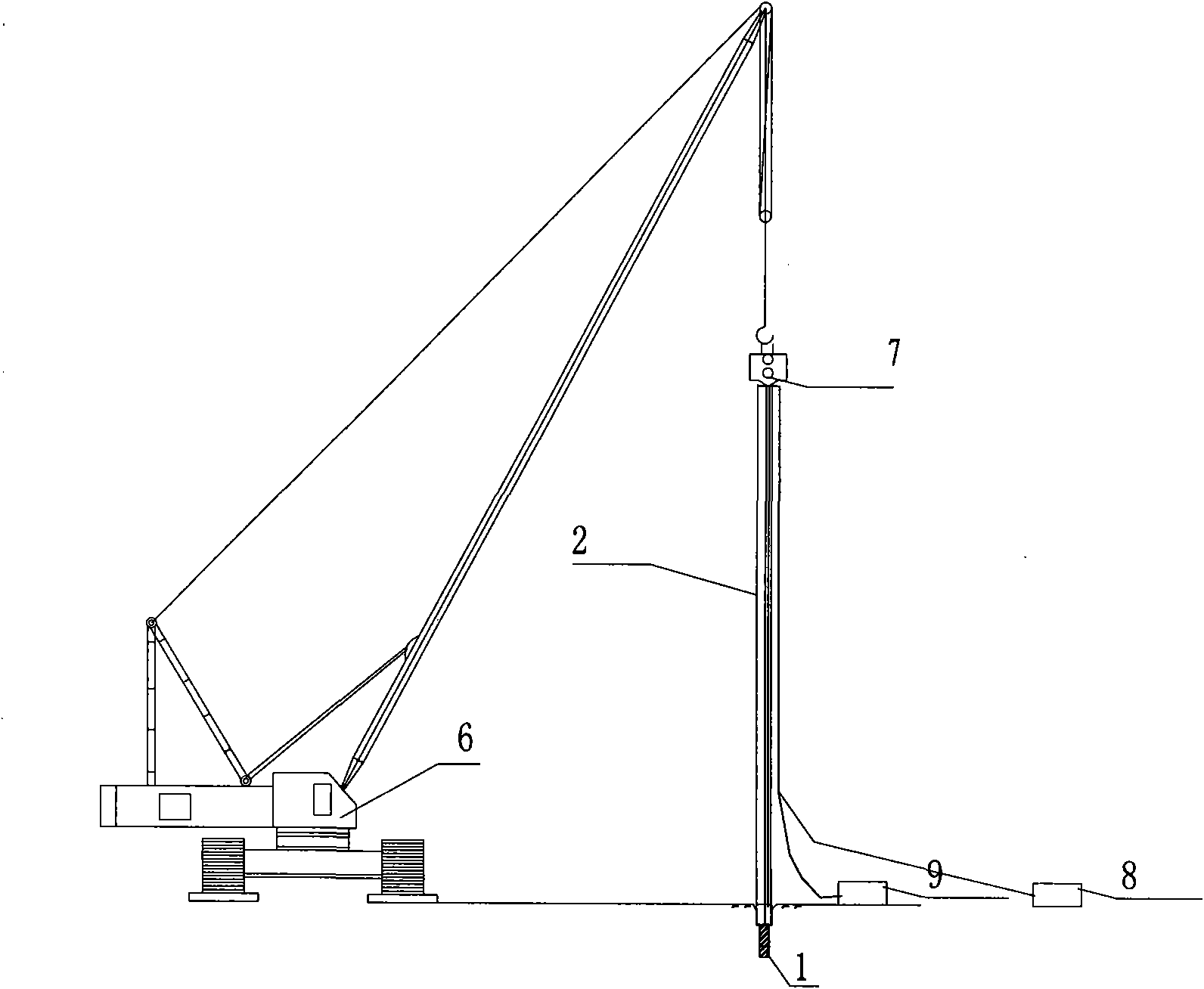

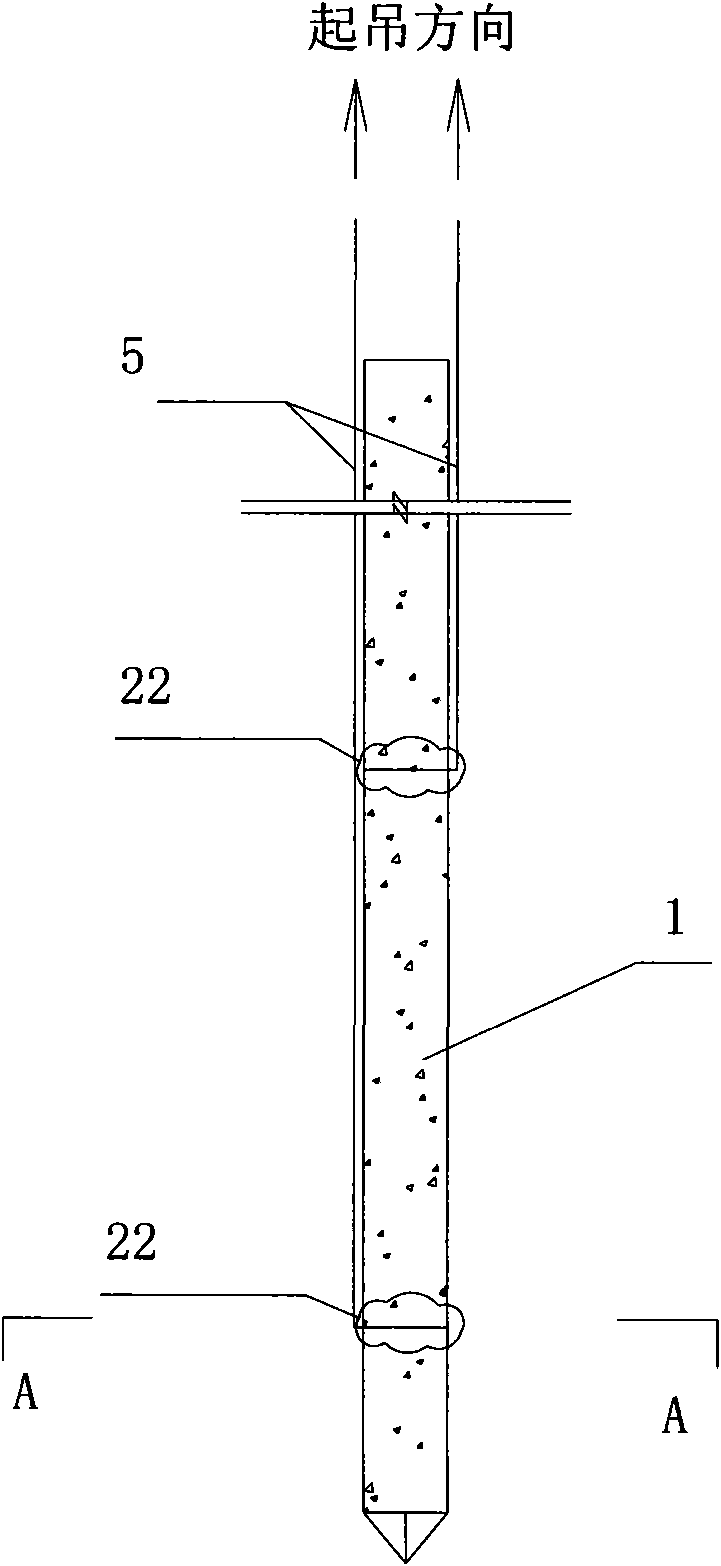

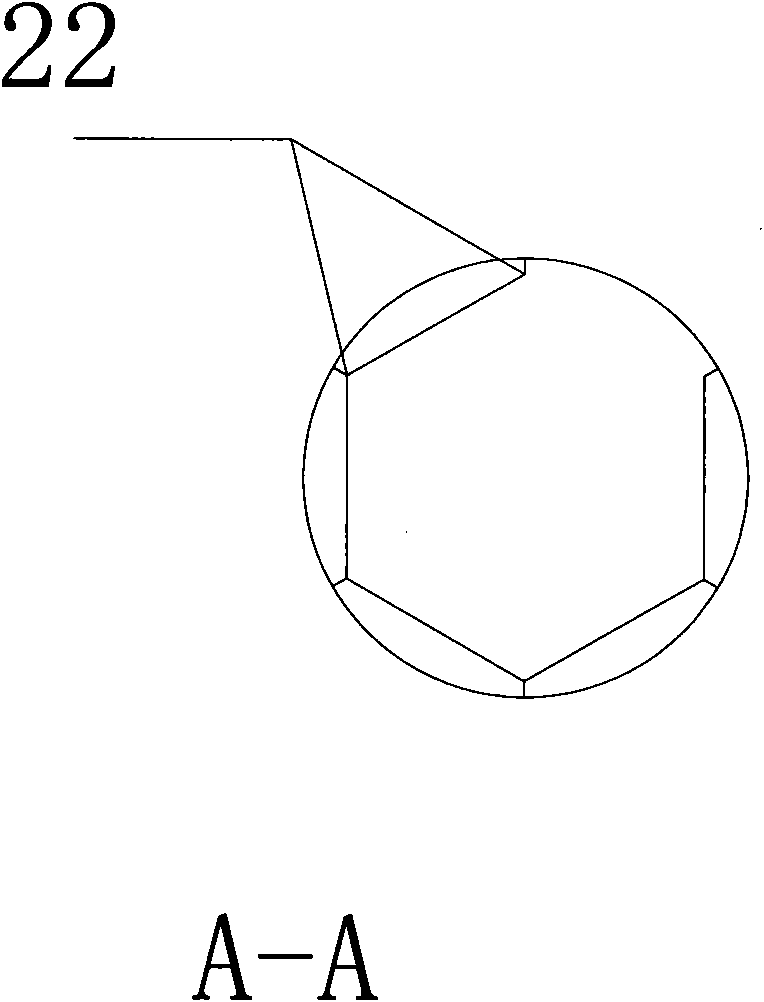

[0027] Such as figure 1 , figure 2 , image 3 with Figure 4 Shown: a kind of underground pile casing pipe vibration punching and pulling out method, it comprises the following steps:

[0028] Sleeve production: take a long steel pipe as the casing 2, set the water pipe 3 and the ventilation pipe 4 on its outer wall, and one end is a zigzag 21, and the upper circumference of the casing 2 inner wall is provided with an earring 22 for placing a steel wire rope 5, so The steel wire rope 5 has two upper and lower wire ropes, each wire rope 5 is wound into a circle through a U-shaped clamp 51 to surround the underground pile 1, one end is connected to the U-shaped clamp 51, and the other end extends to the outside of the casing 2;

[0029] Determine the position of the pile head: compare the design position of the new structure according to the measurement and positioning, excavate the trench and expose the pile head, and determine the pile position to be removed;

[0030] Rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com