Sealed replacing tool and method of ordinary-pressure cutter replacement device of shield tunneling machine

A technology of tool changing device and shield machine, which is used in earth-moving drilling, manufacturing tools, mining equipment, etc., can solve the problems of high personal safety risk of dismantling personnel, deterioration of sealing performance, affecting construction progress, etc., so as to ensure the overall construction progress. , to ensure safety, to ensure the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

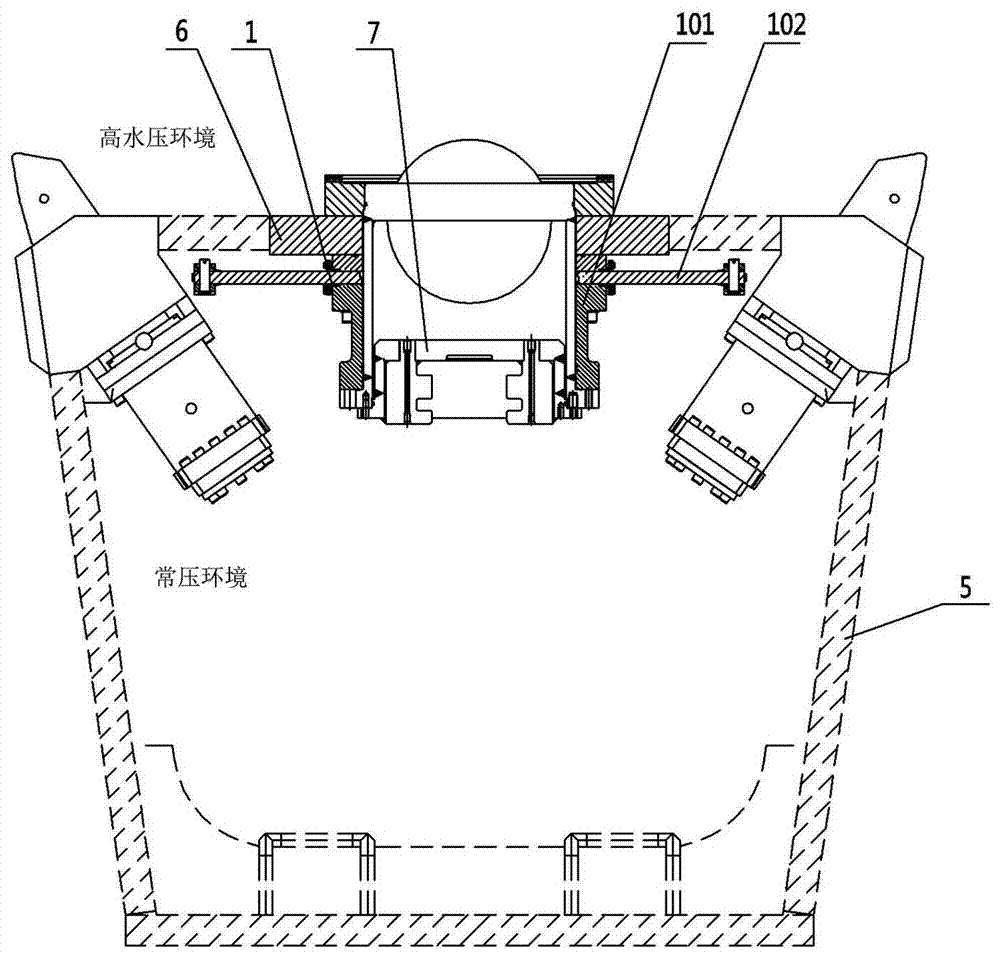

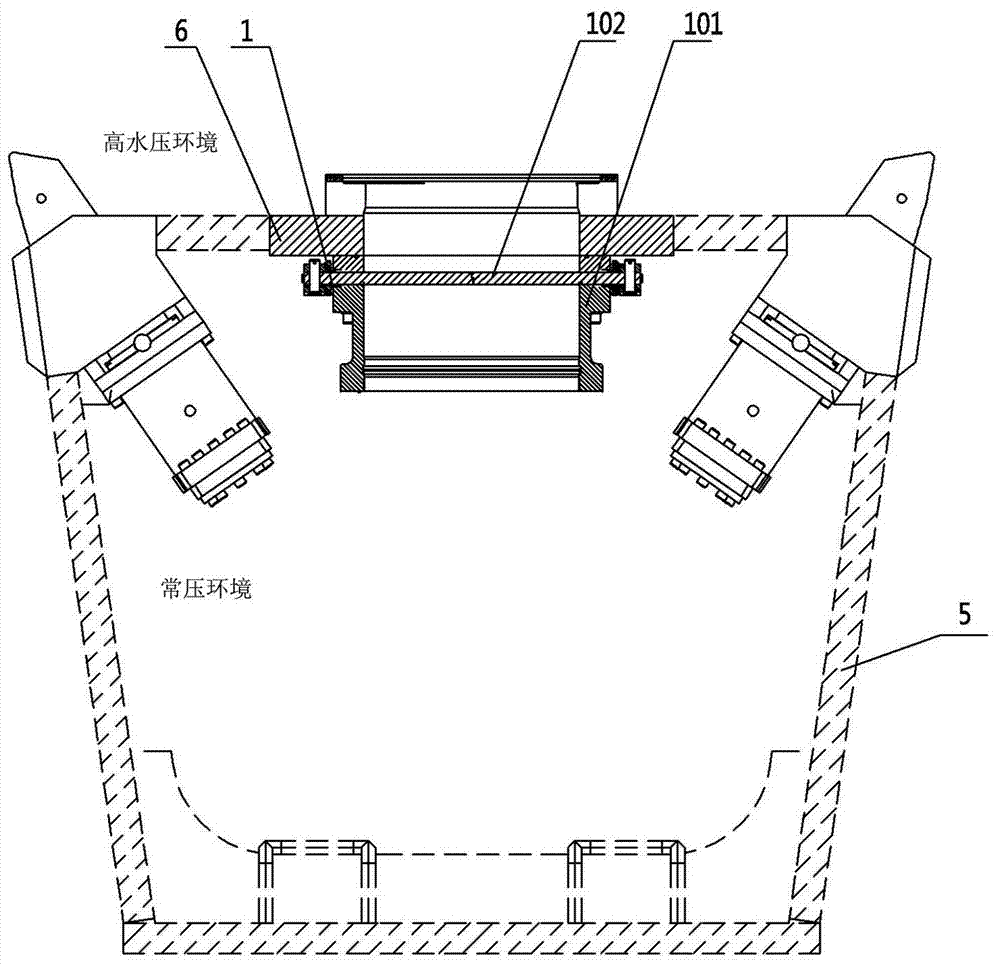

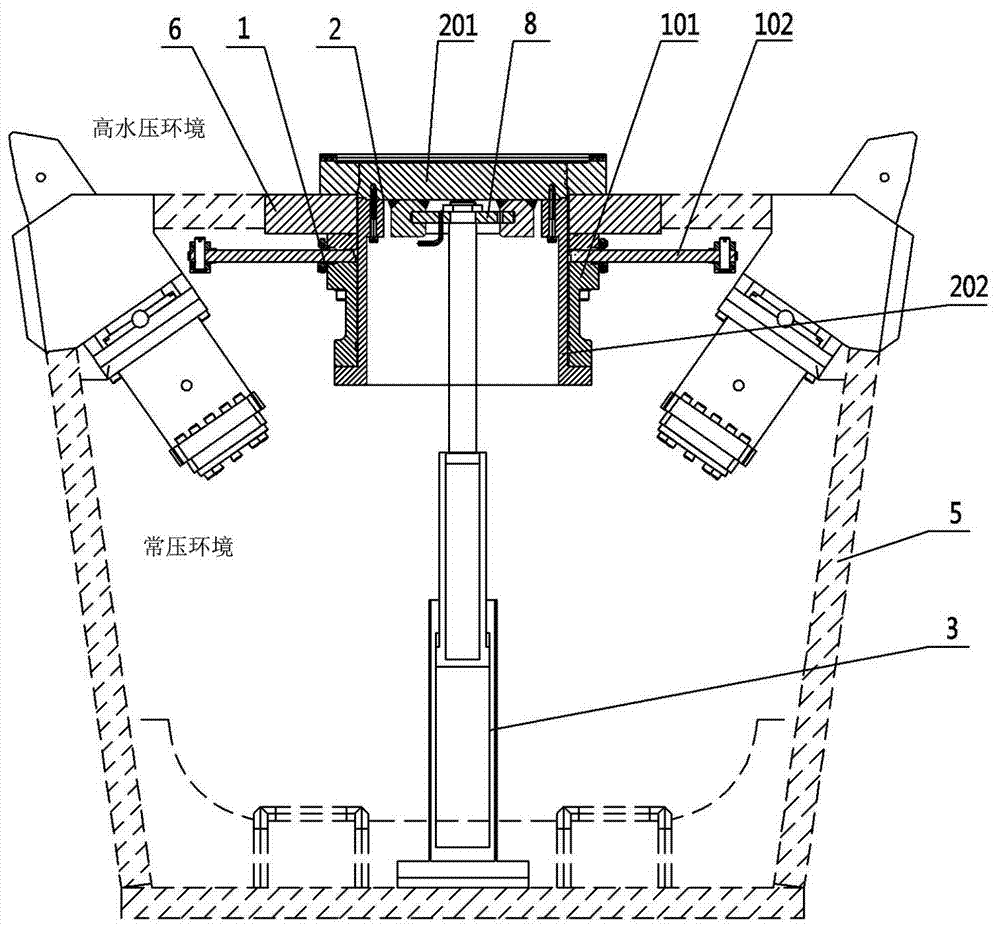

Embodiment 1

[0032] A shield machine atmospheric pressure tool changing device seal replacement tooling of the present invention includes a support cylinder 3, a seal cylinder 2 and a support seat 4, the seal cylinder 2 includes a cylinder front cover 201 and a cylinder rear support 202, The cylinder front cover 201 and the cylinder rear support 202 are connected together by bolts; the outer circumference of the cylinder front cover 201 is a tapered structure, and the welding seat 6 of the knife arm beam 5 of the shield machine is vertically provided with The inner tapered hole matched with the cylindrical front cover 201, the cylindrical front cover 201 and the welding seat 6 are installed in a limited position through the mechanical cooperation of the cone angle, and the cylindrical rear support 202 is sleeved on the tool change support cylinder 101 of the normal pressure tool change device 1 Inside, an O-ring is provided on the inner wall of the tool change support cylinder 101; a suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com