Steel pipe column bearing table girder connection construction method

A technology of column cap beam and construction method, which is applied in construction, building structure, processing of building materials, etc., can solve the problems of difficult construction of basic beams, large beam cross-section size, slow construction progress, etc., and achieves improved strength. and overall stability, ensuring the three-dimensional space position, and the effect of fast construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

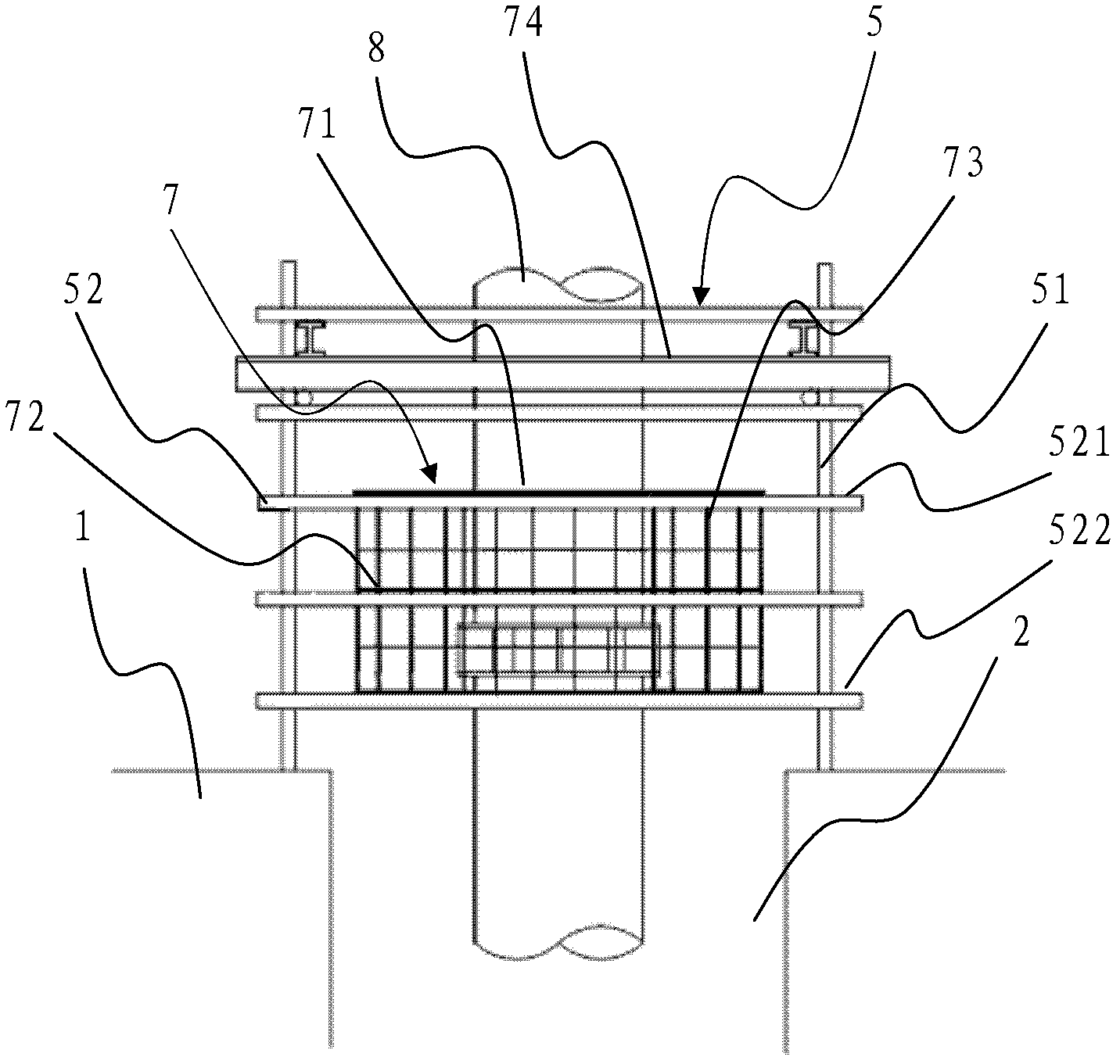

[0062] The present invention will be further described below in conjunction with specific examples.

[0063] A construction method for a steel pipe column cap beam joint of the present invention comprises the following steps:

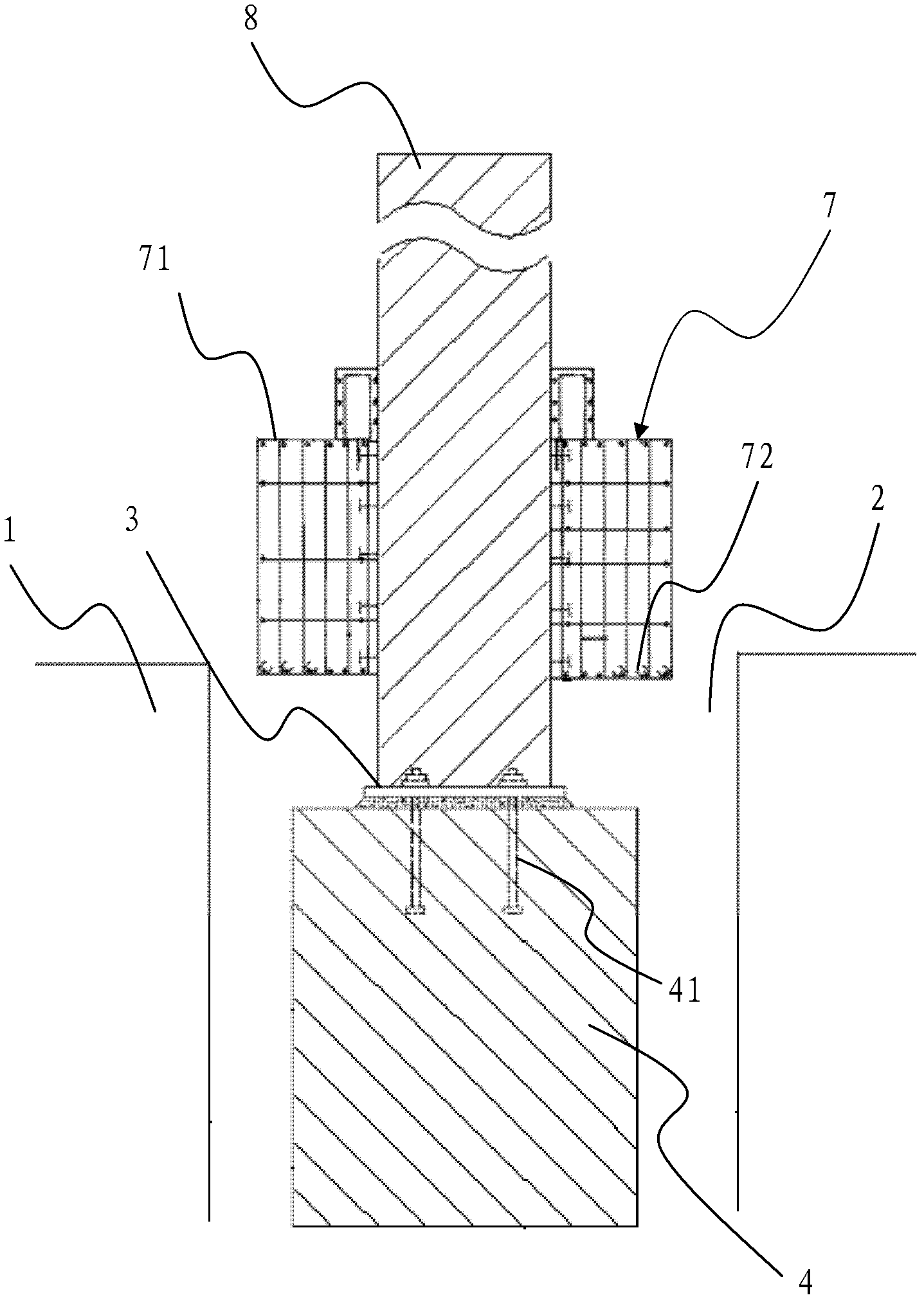

[0064] First, see figure 1 , laying the floor cushion 1 and laying a waterproof layer on the floor cushion 1;

[0065] Then, the steel pipe column bottom plate 3 is installed in the platform foundation pit 2;

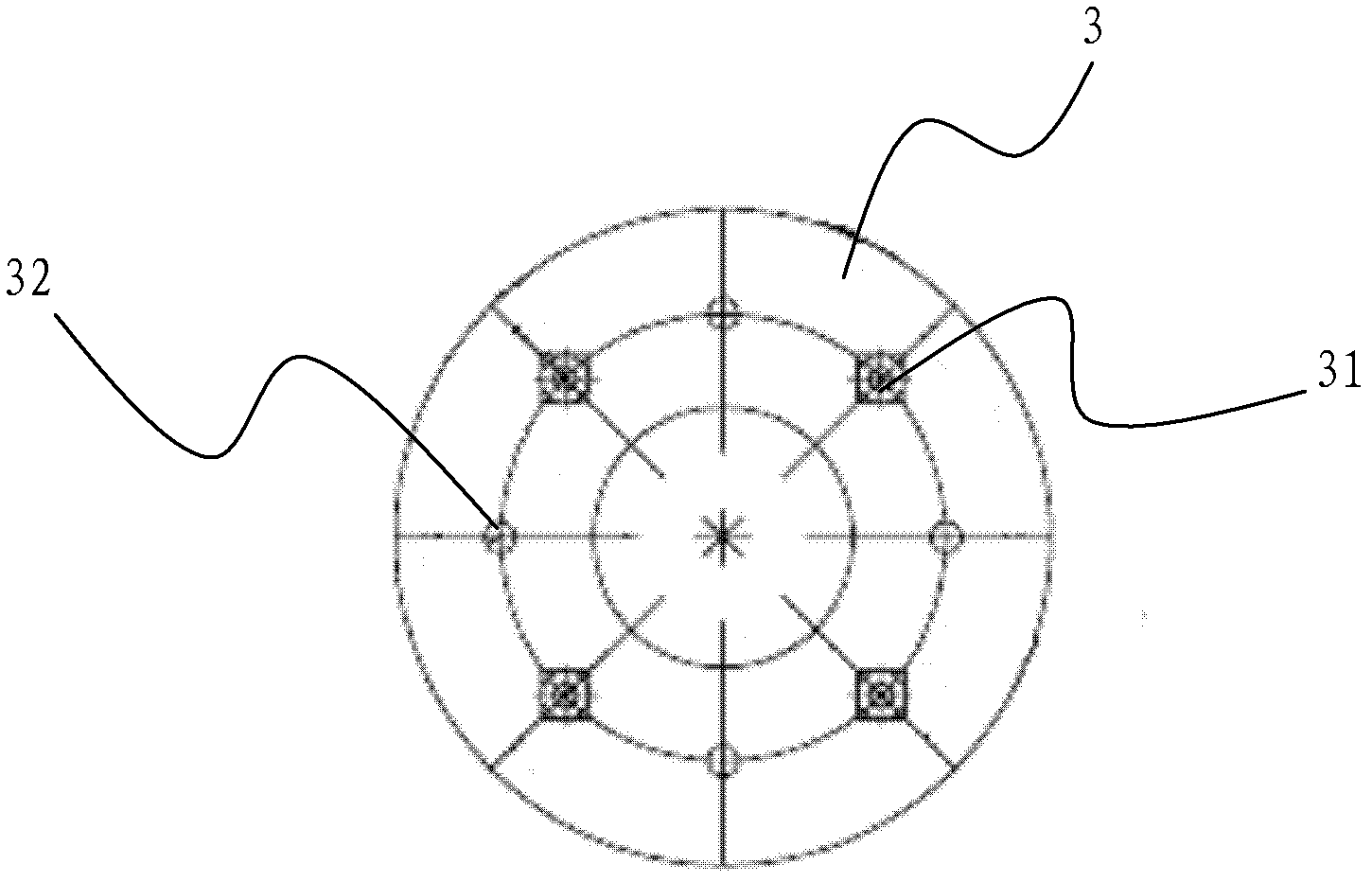

[0066] see figure 1 , figure 2 , the 3 steps of installing steel pipe column bottom plate include:

[0067] A plurality of anchor bolts 41 are pre-embedded on the manual excavation pile 4 in the foundation pit of the cap 2;

[0068] Put a steel pipe column bottom plate 3 with a plurality of anchor bolt holes 31 inside on the anchor bolt 41;

[0069] Adjust and fix the bottom plate 3 of the steel pipe column at an elevation position, fix the bottom plate 3 of the steel pipe column with nuts and gaskets, and weld the nuts and gaskets firmly;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com