High-altitude long-span roofing pipe truss installation method

An installation method and technology of pipe trusses, which are applied in the directions of construction, building structure, and building materials processing, etc., can solve problems such as difficult construction, large spans, and heavy weight of installed pipe trusses, so as to improve construction quality and ensure construction safety , to ensure the effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

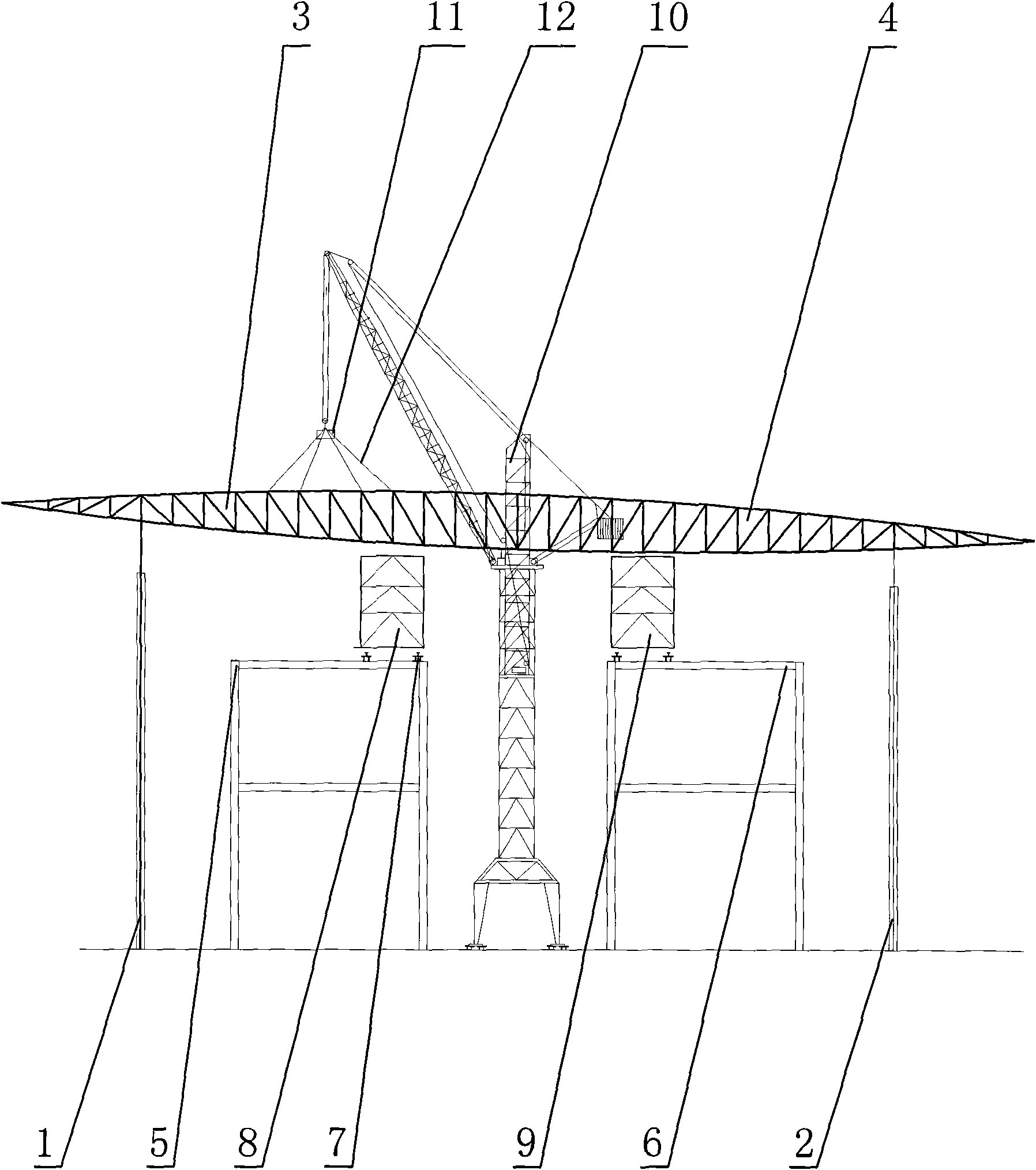

[0017] Accompanying drawing is the structural representation of the present invention, as shown in the figure: the installation method of high-altitude large-span roof pipe truss comprises the following steps:

[0018] a. The pipe trusses are assembled on the ground. The number of pipe trusses is mainly determined according to the length of the roof. If a pipe truss is installed at an interval of 12m or 9m; and each pipe truss is composed of several sections, it is mainly based on the span of the roof and the mobile tower crane plane position and rated lifting capacity, the span of the pipe truss in this embodiment is the distance (such as 96m) between the left reinforced concrete column 1 and the right reinforced concrete column 2, and the mobile tower crane 10 selects TQ1000 / 60 mobile tower crane, the mobile tower crane The radius of gyration is 24m, so the pipe truss in this embodiment is composed of two pipe trusses (namely, the left pipe truss 3 and the right pipe truss 4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com