Formwork system of shear walls at two sides of extensible seam

A technology of expansion joints and shear walls, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc. To meet the fire protection requirements and other issues, to achieve the effect of shortening the construction period, small construction space, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

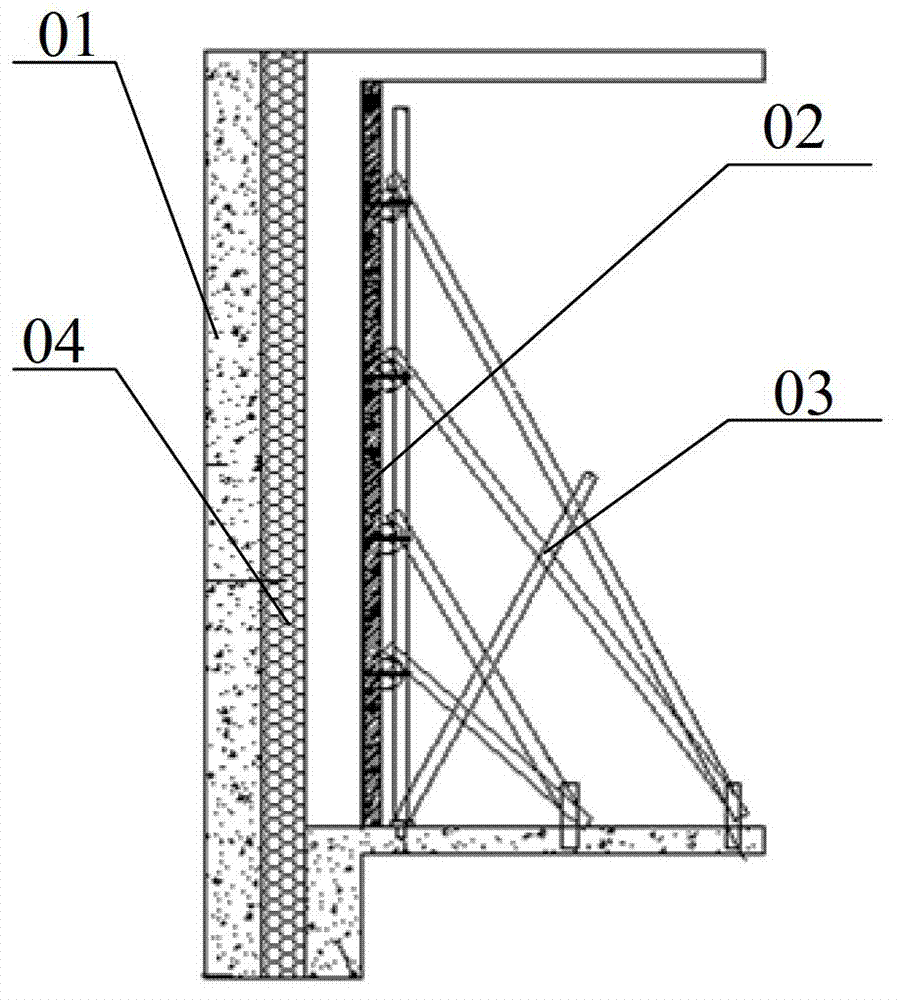

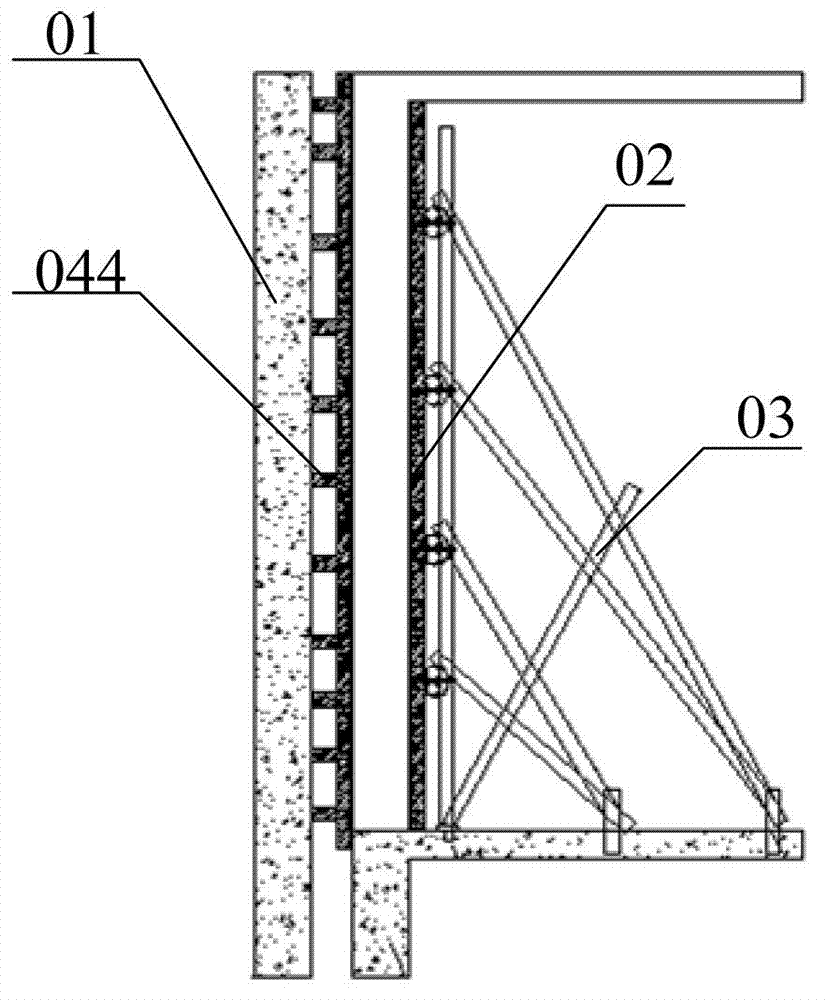

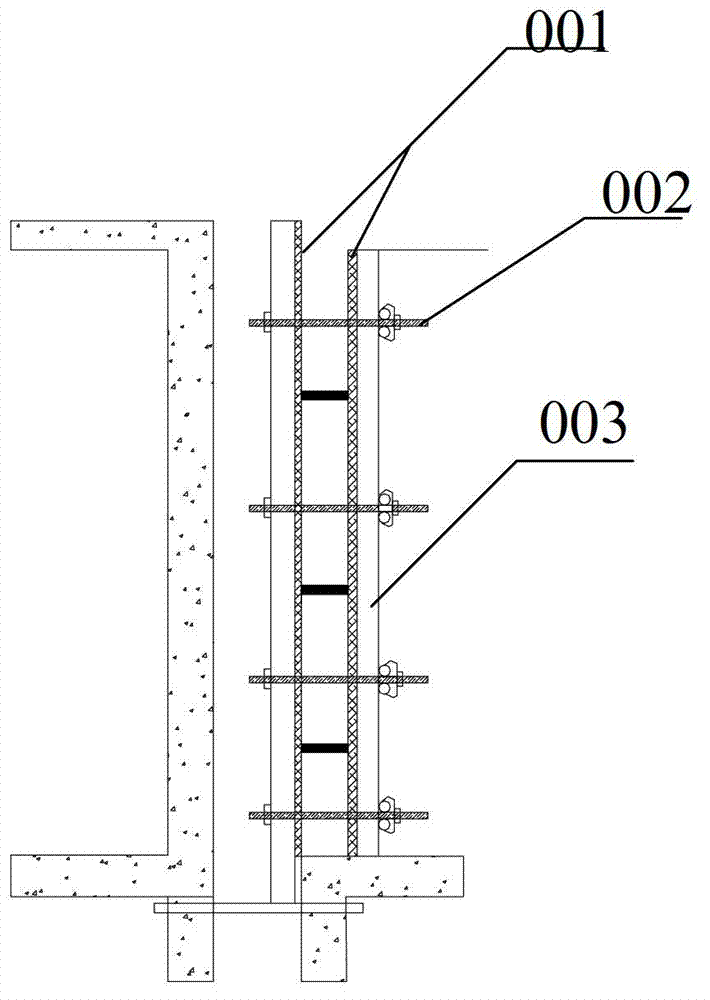

[0030] The purpose of the present invention is to provide a shear wall formwork system on both sides of the expansion joint. The shear wall formwork system on both sides of the expansion joint is provided with two sets of wall casting molds symmetrical about the expansion joint on both sides of the expansion joint, and through the side The fastening steel pipe and the end fastening steel pipe realize the fastening of the pouring mold. The shear wall formwork system on both sides of the expansion joint can support the pouring mold of the shear wall on both sides of the expansion joint at one time, so as to realize the shear wall on both sides of the expansion joint. The simultaneous pouring of the force wall can greatly shorten the construction period and ensure the construction progress.

[0031] In order to enable those skilled in the art to better understand the solutions of the present invention, the present invention will be further described in detail below in conjunction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com