Patents

Literature

51results about How to "Improve insertion speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

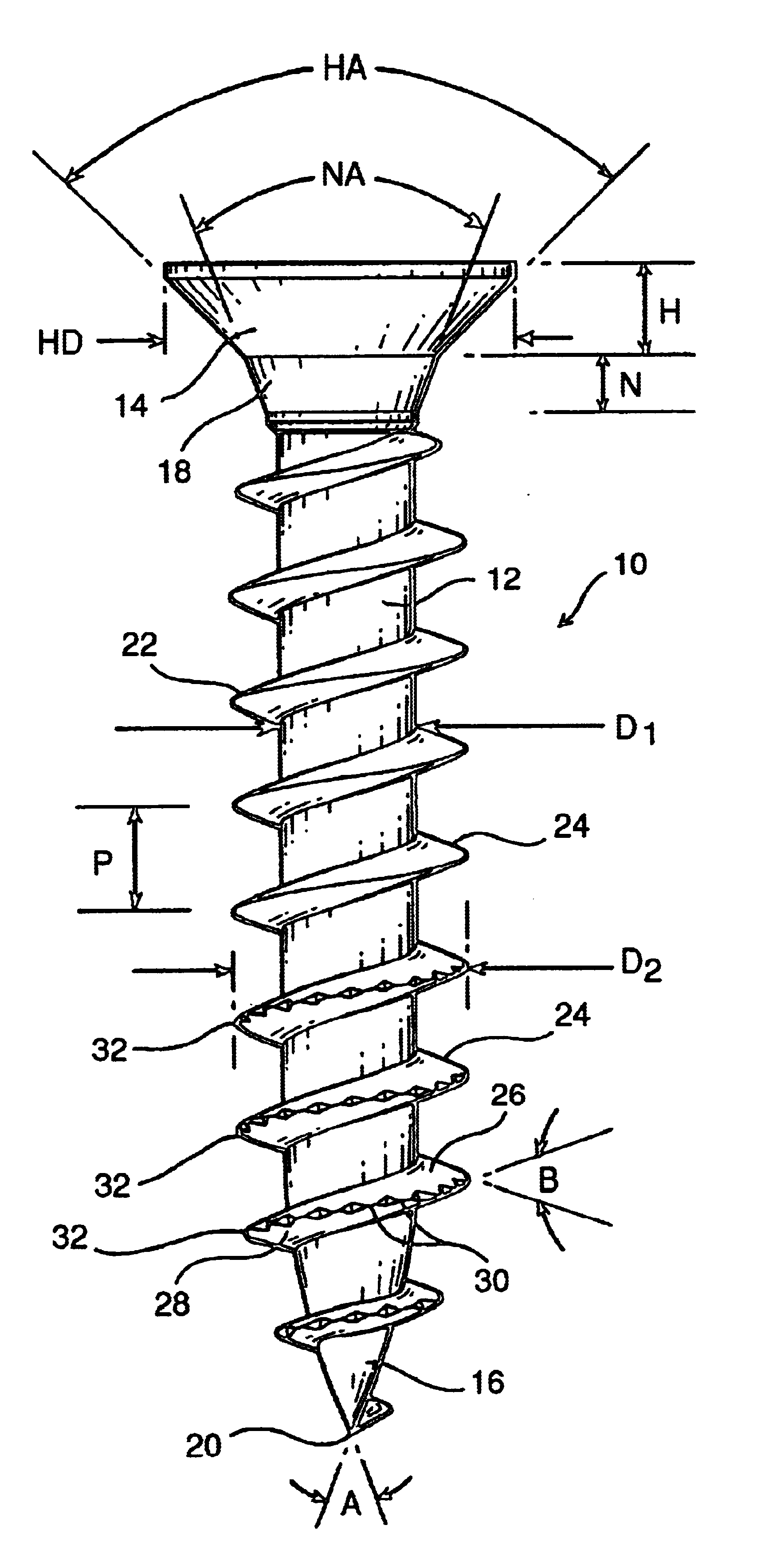

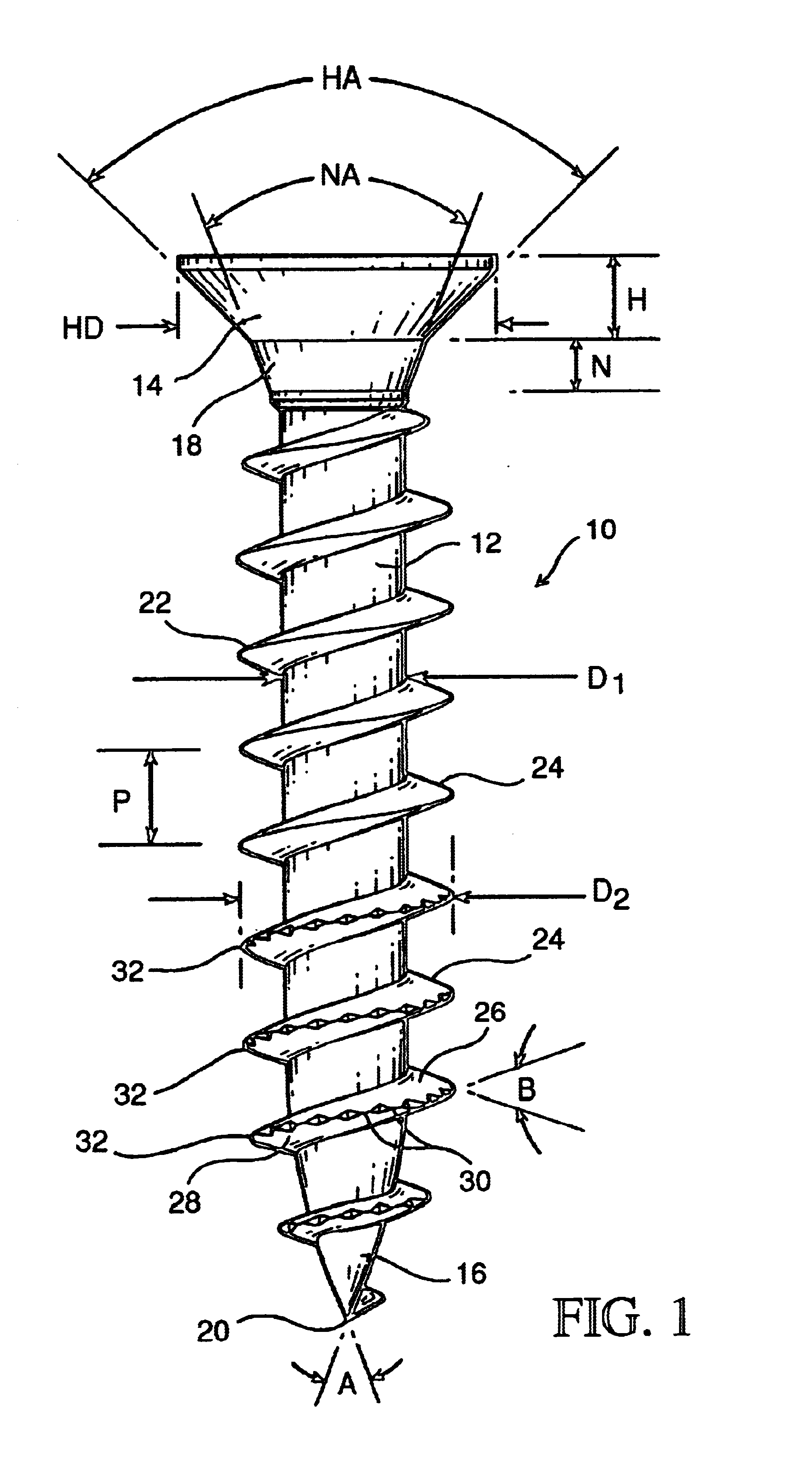

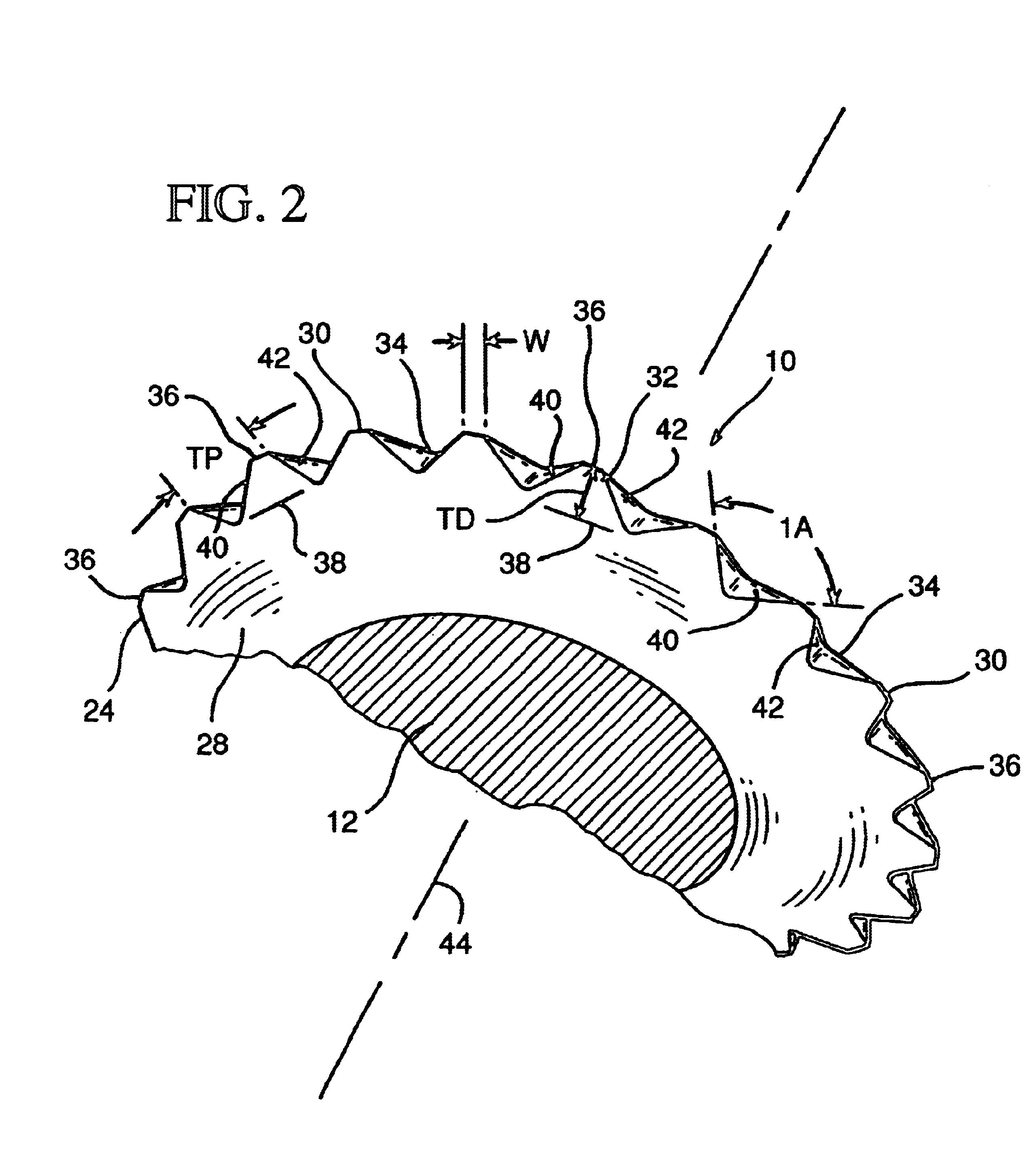

Threaded fastener for use within multiple substrates

A threaded fastener has a substantially single helical thread formed upon a shank portion thereof, and a plurality of substantially saw-blade type or serrated teeth are formed upon crest portions of leading ones of individual thread portions of the helical thread. The threads of the threaded screw fastener are also characterized by means of predetermined flank angles, and such flank angles, in conjunction with the saw-blade type or serrated teeth, permit the threaded screw fastener of the present invention to be utilized within any one of a multiplicity of substrates, such as, for example, wood, metal, thermoplastics, composite materials, concrete, hard aggregate, or the like.

Owner:ILLINOIS TOOL WORKS INC

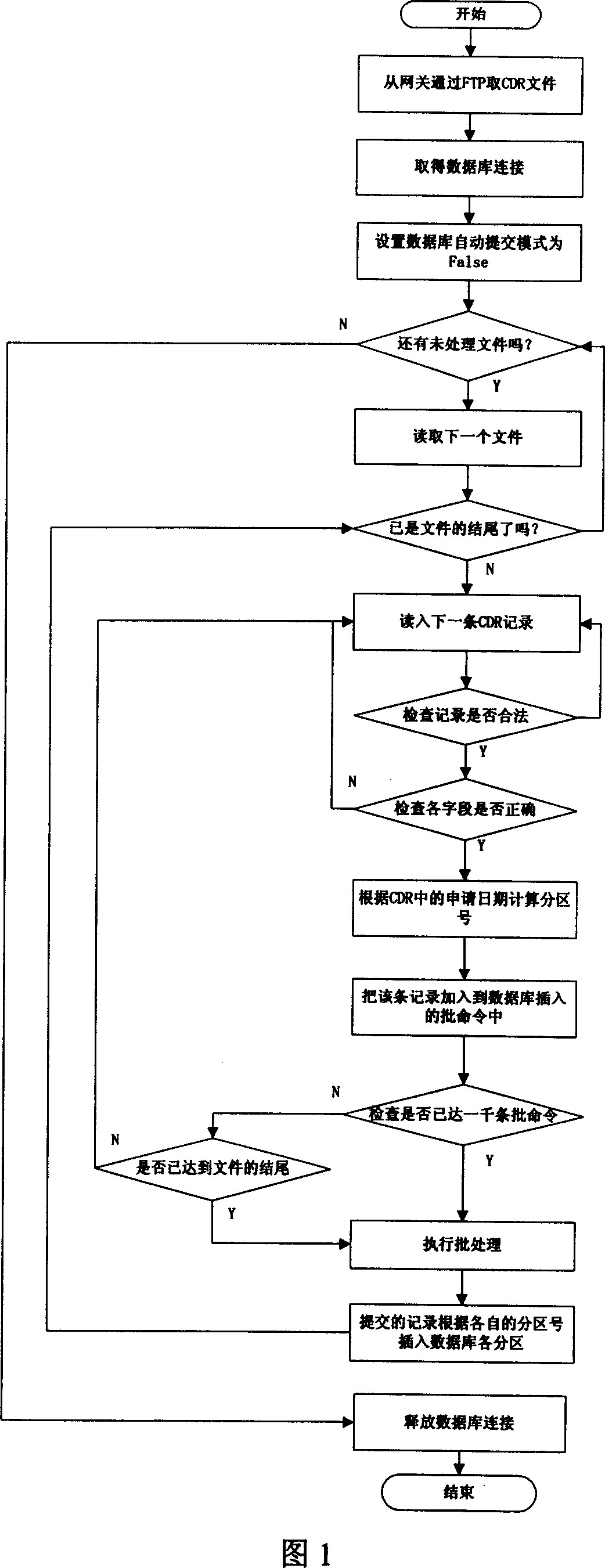

A high magnitude of data management method

InactiveCN101086732AReduce overheadImprove insertion speedSpecial data processing applicationsSoftware systemData management

A large amount data management method divides the data base into several zones, with each being a small data base marked with dates, data inserted into the zones in sequence and updated in the number limit, and establishing five more data base list space for further improving the data base parallel and inquiry efficiency. It can avoid the slowing down of overall application system efficiency due to large amount of data, with reduced running expenses and improved efficiency.

Owner:上海全成通信技术有限公司

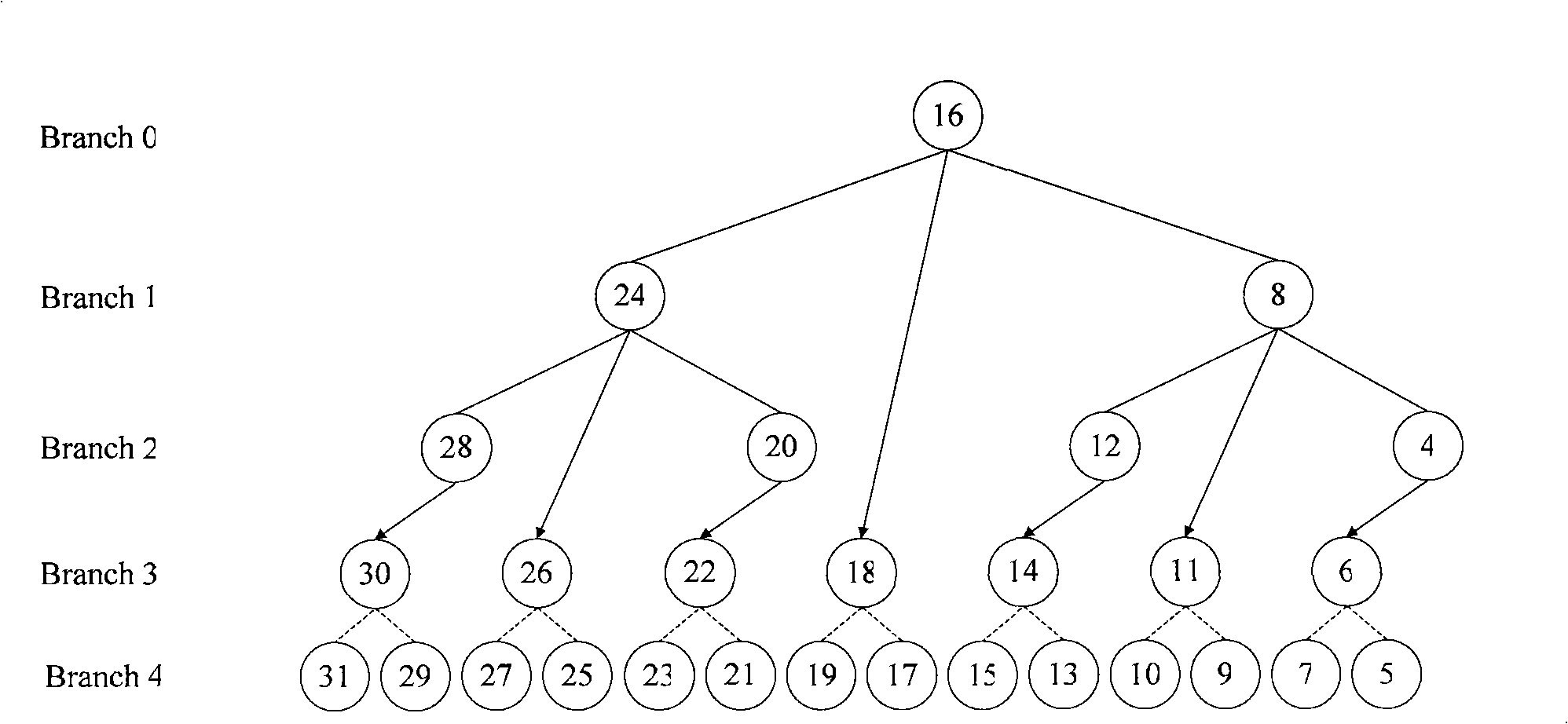

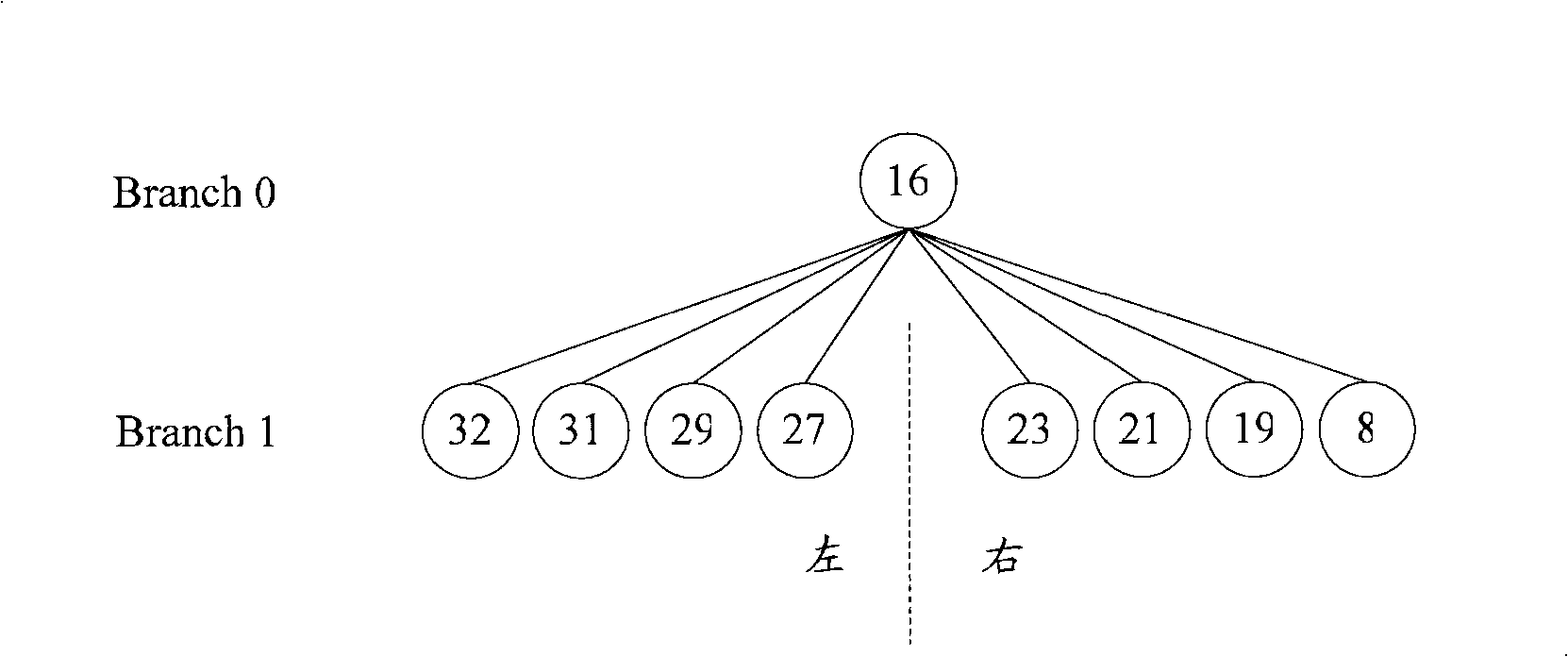

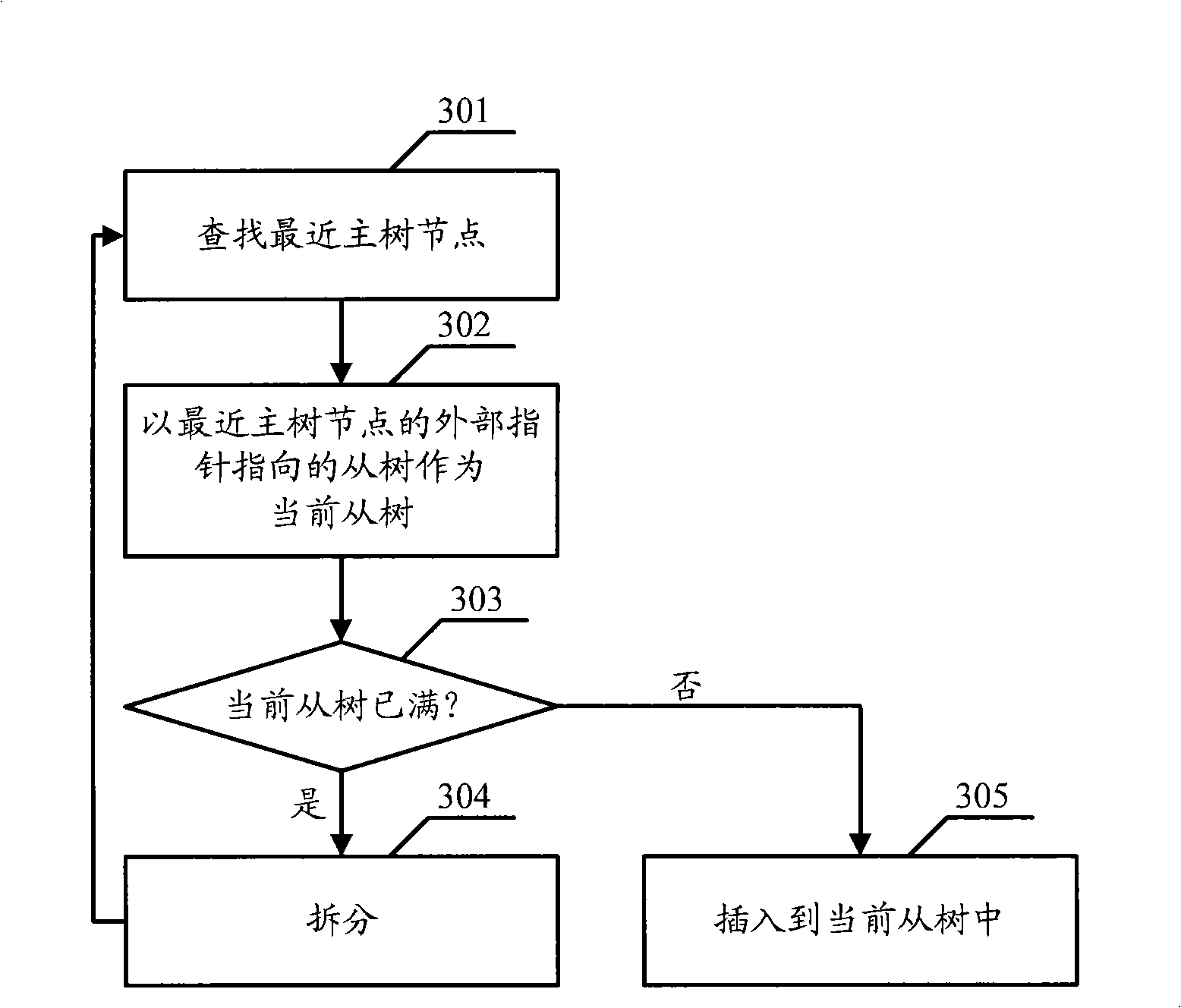

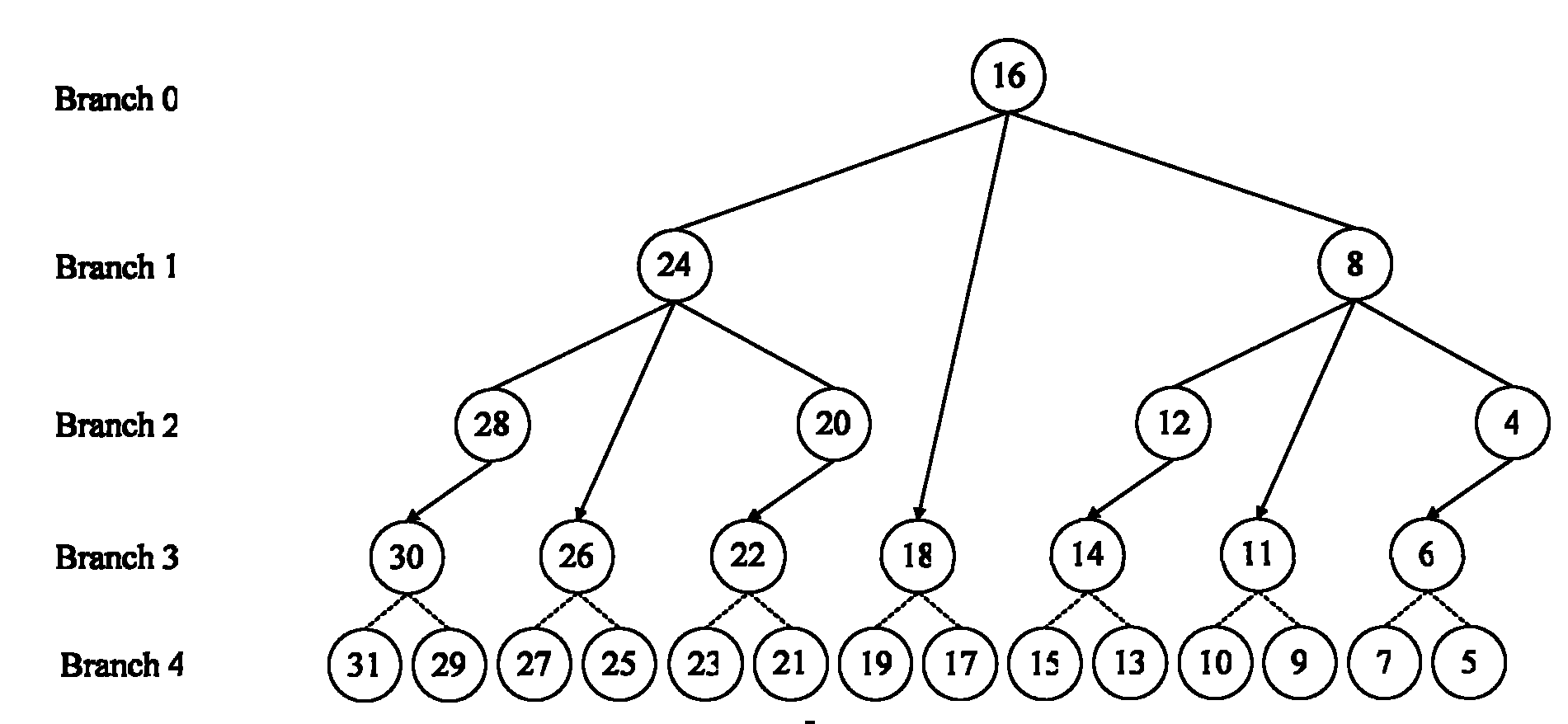

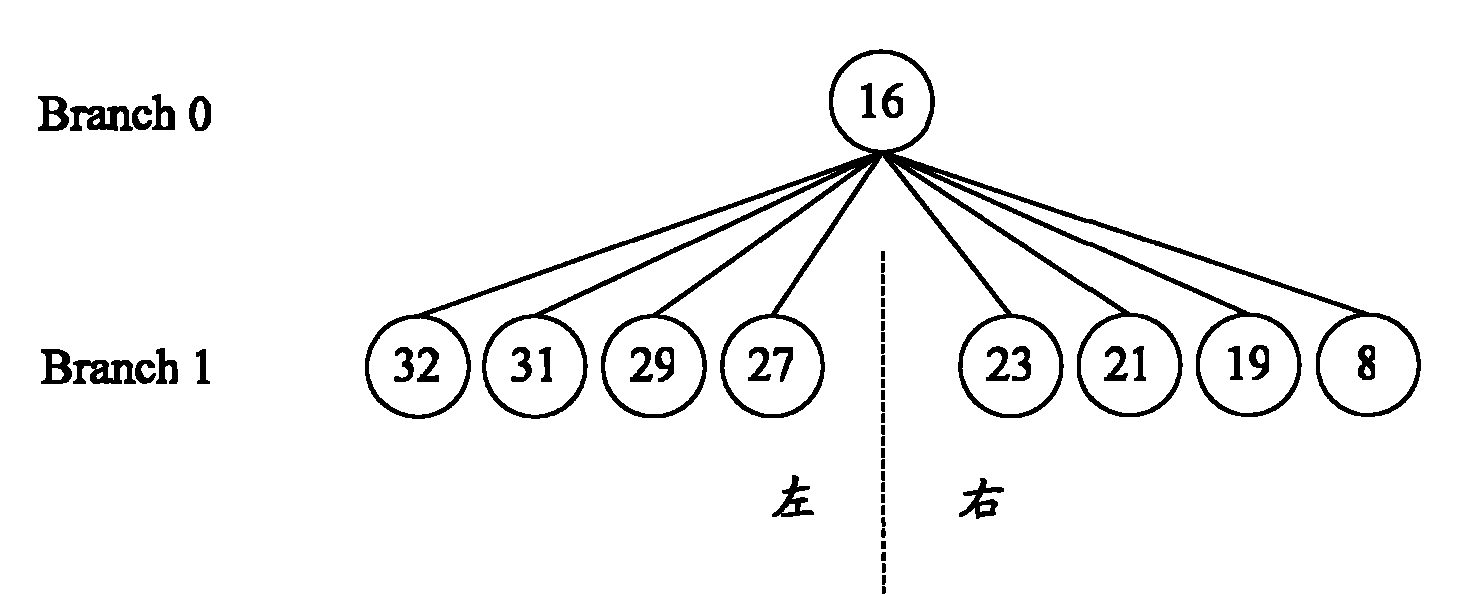

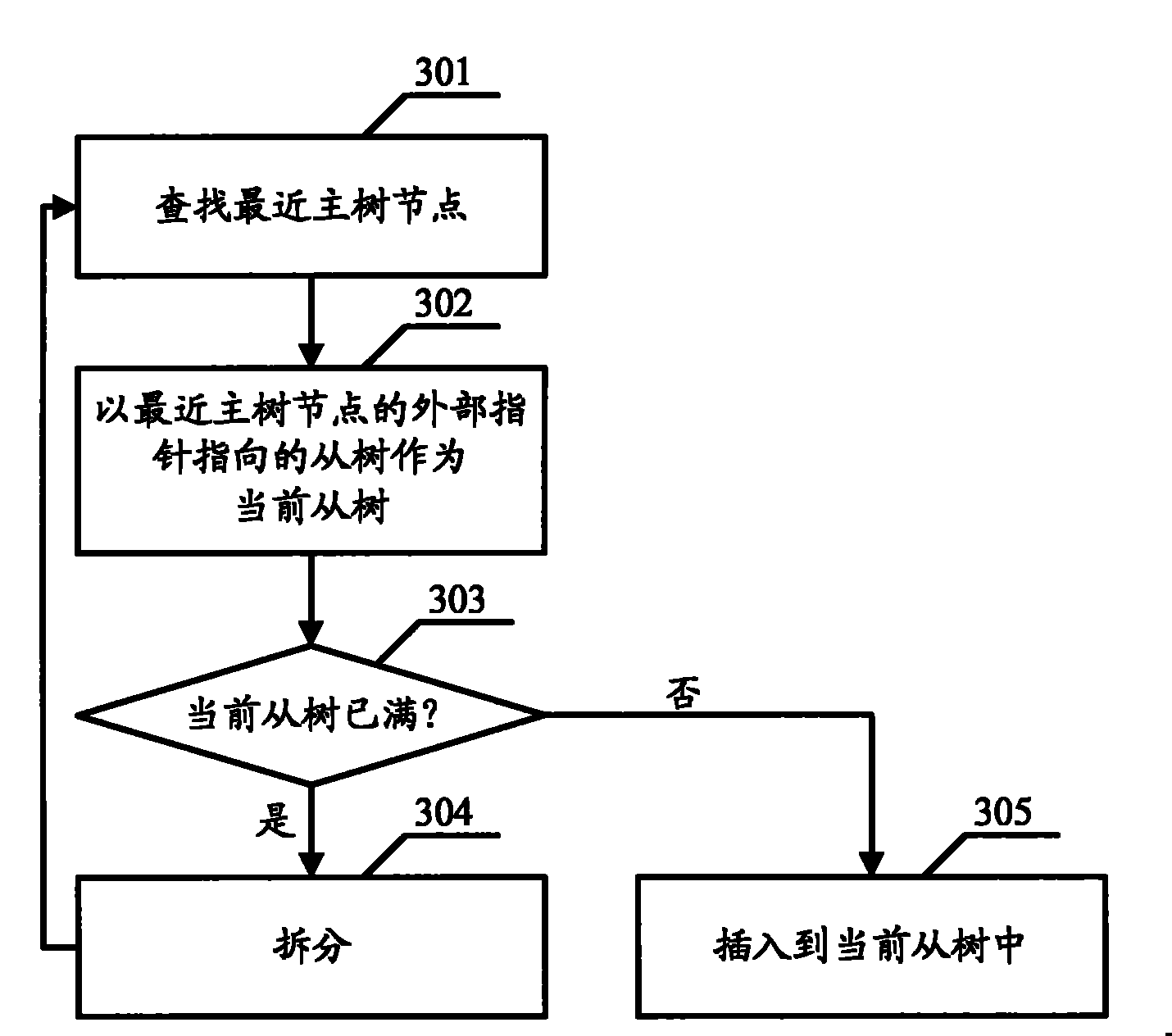

Inserting method based on tree-shaped data structure node and storing device

ActiveCN101515298ALower the altitudeReduce insertion timeDigital data information retrievalKnowledge representationArray data structureTheoretical computer science

The embodiment of the present invention discloses an inserting method based on tree-shaped data structure node and a storing device. The method includes steps of searching nearest main tree node according to key code value of node to be inserted, wherein the key code value of the nearest main tree node is smaller than and nearest to the key code value of the node to be inserted; using a secondarytree pointed by an external pointer of the nearest main tree node as present secondary tree, judging whether the present secondary tree is full, if yes, arbitrarily selecting a node in the present secondary tree as a split node, inserting the split node into the main tree as a newly-built main tree node, distributing newly-built secondary tree for the newly-built main tree, making an external pointer of the newly-built main tree node point to the newly-built secondary tree, moving all nodes arranged at left side of the split node in the present secondary tree in the newly-built secondary tree, then searching nearest main tree node, if not, inserting the node to be inserted into the present secondary tree. The invention divides the tree of the tree-shaped data structure into main tree and secondary tree, thereby reducing height of the tree and node inserting time.

Owner:HUAWEI TECH CO LTD

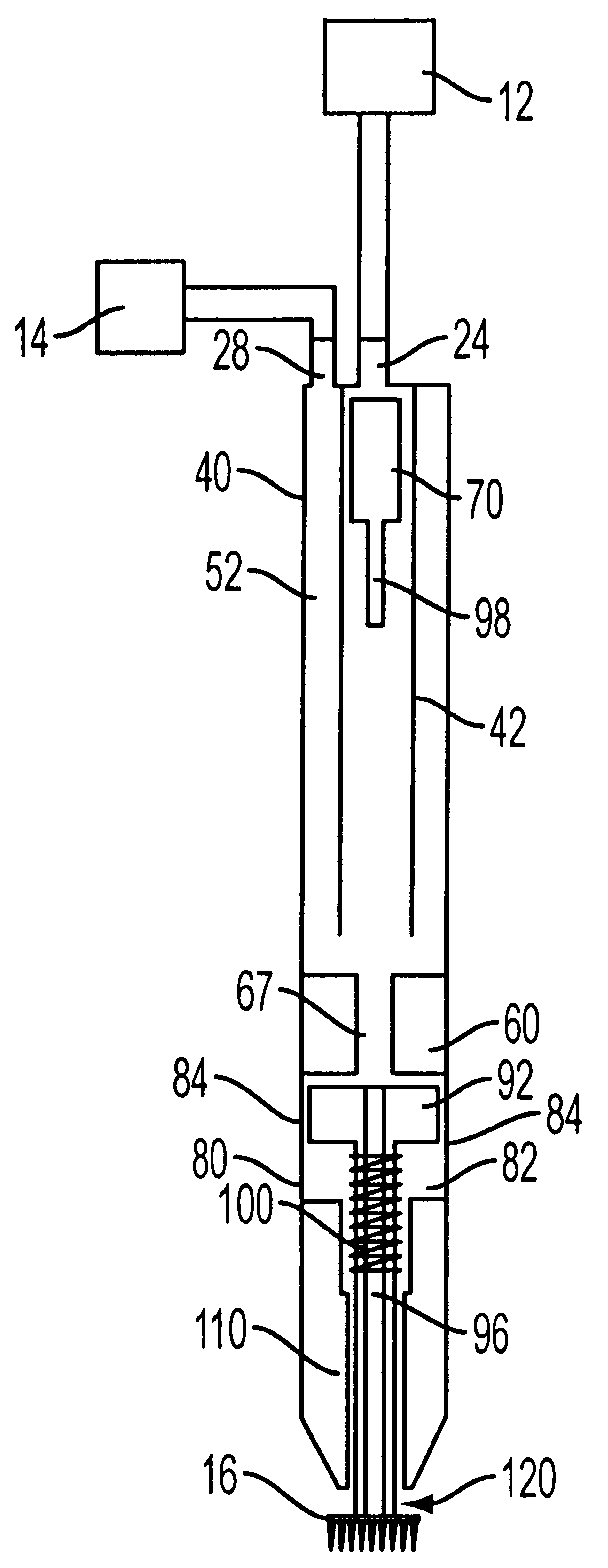

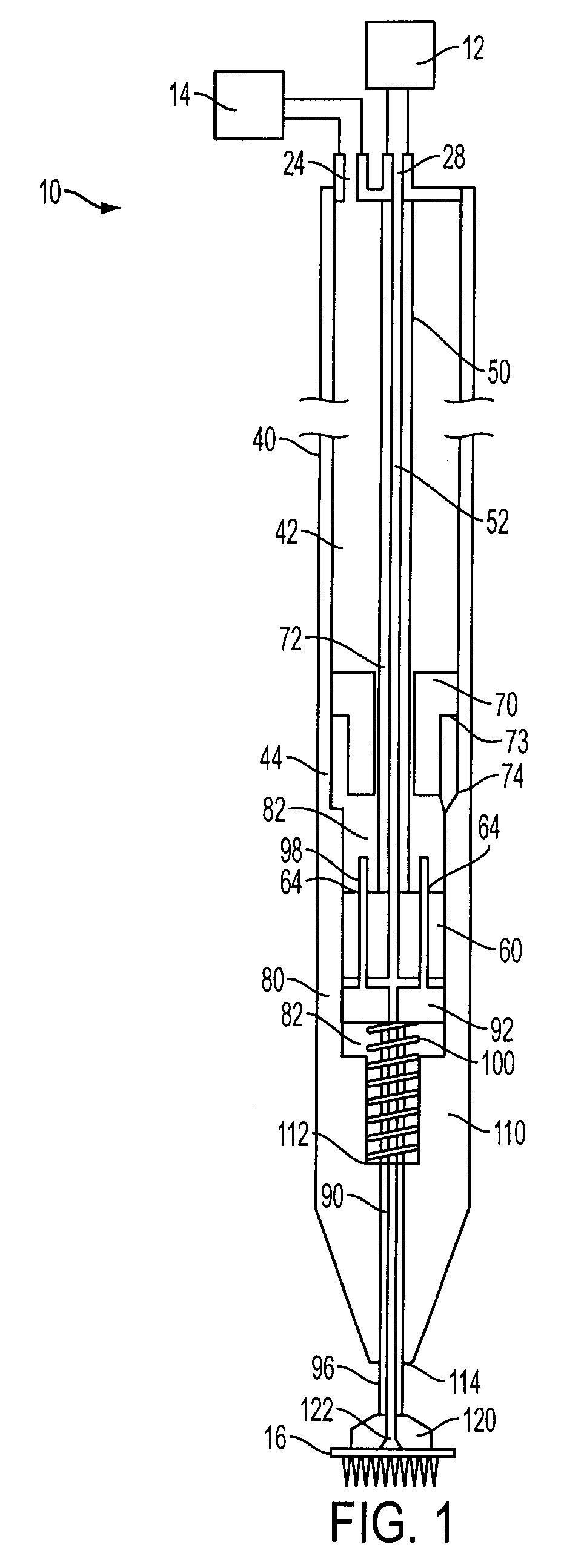

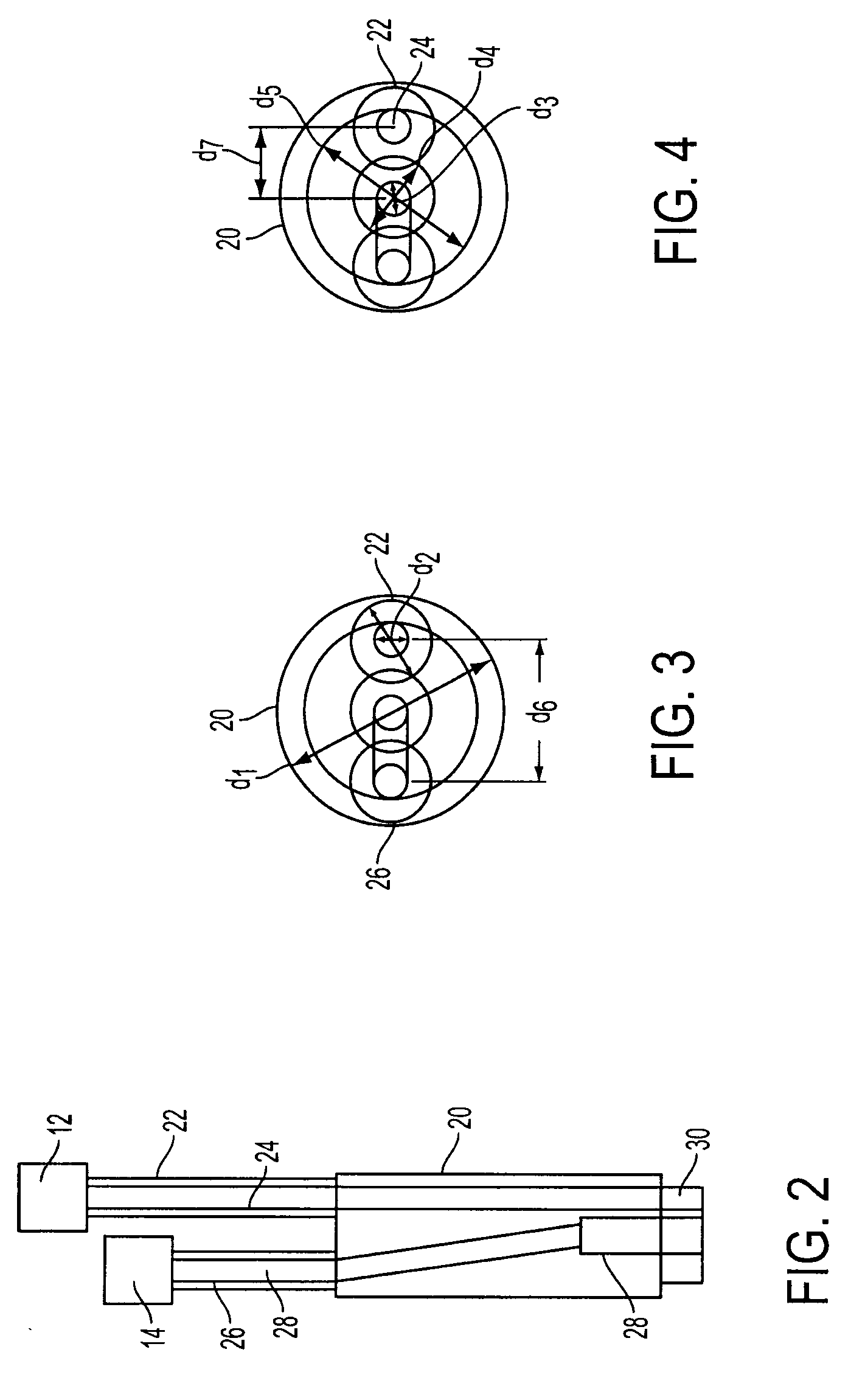

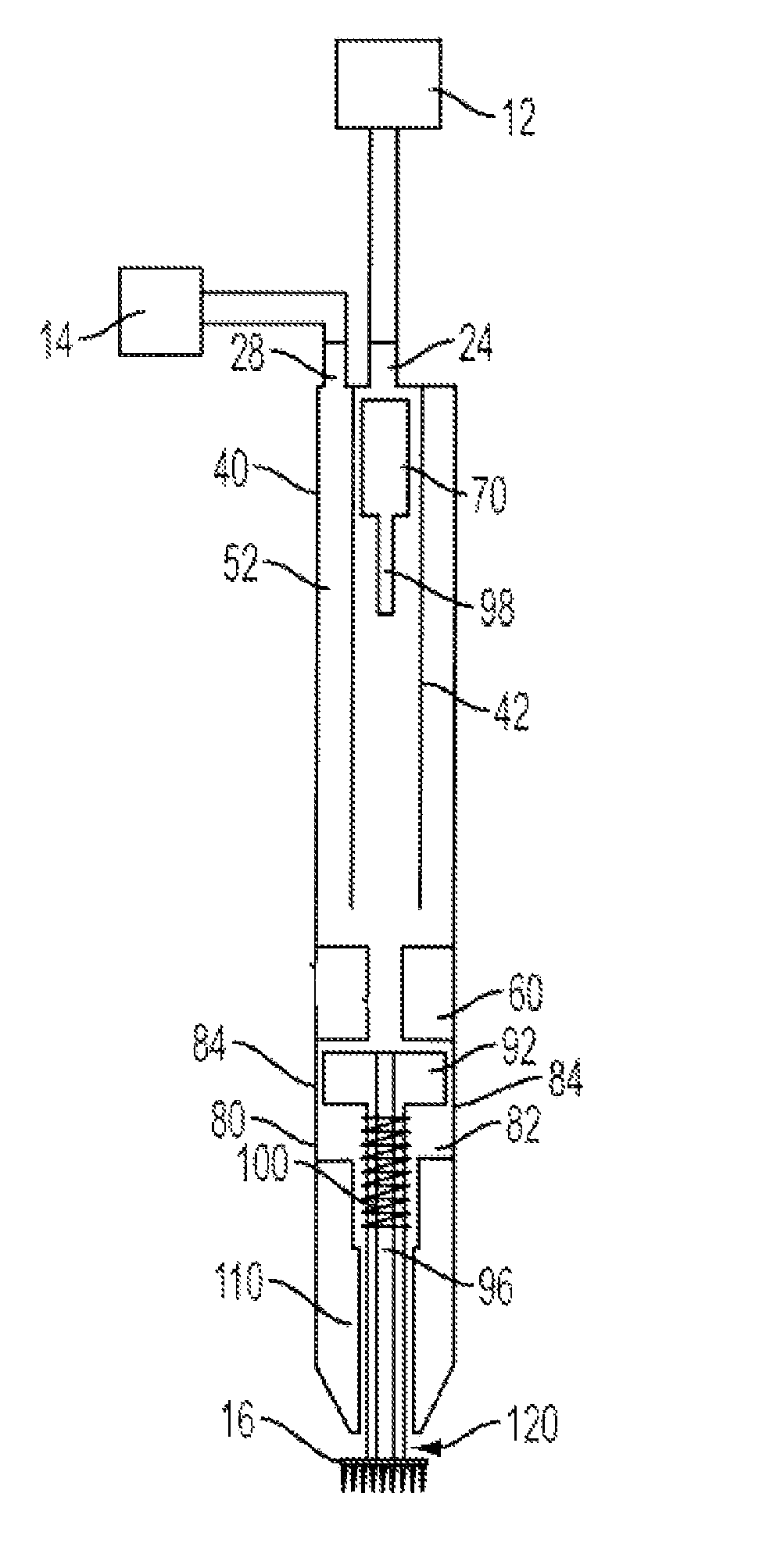

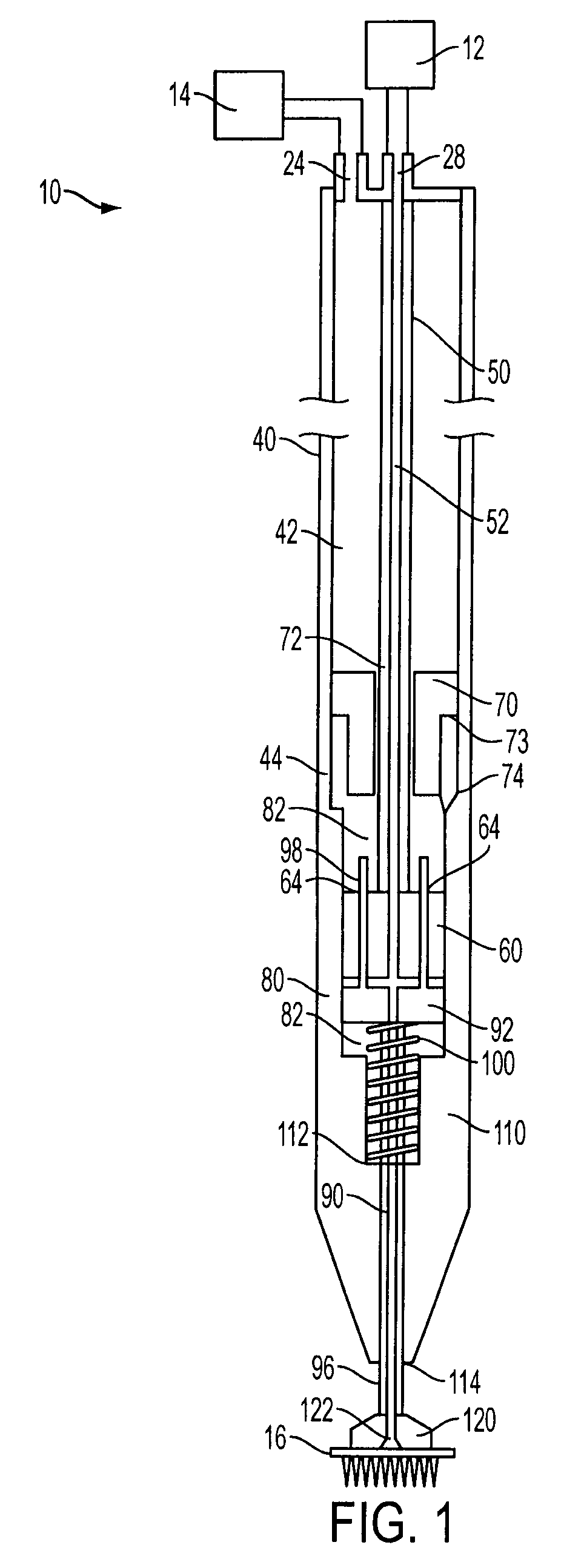

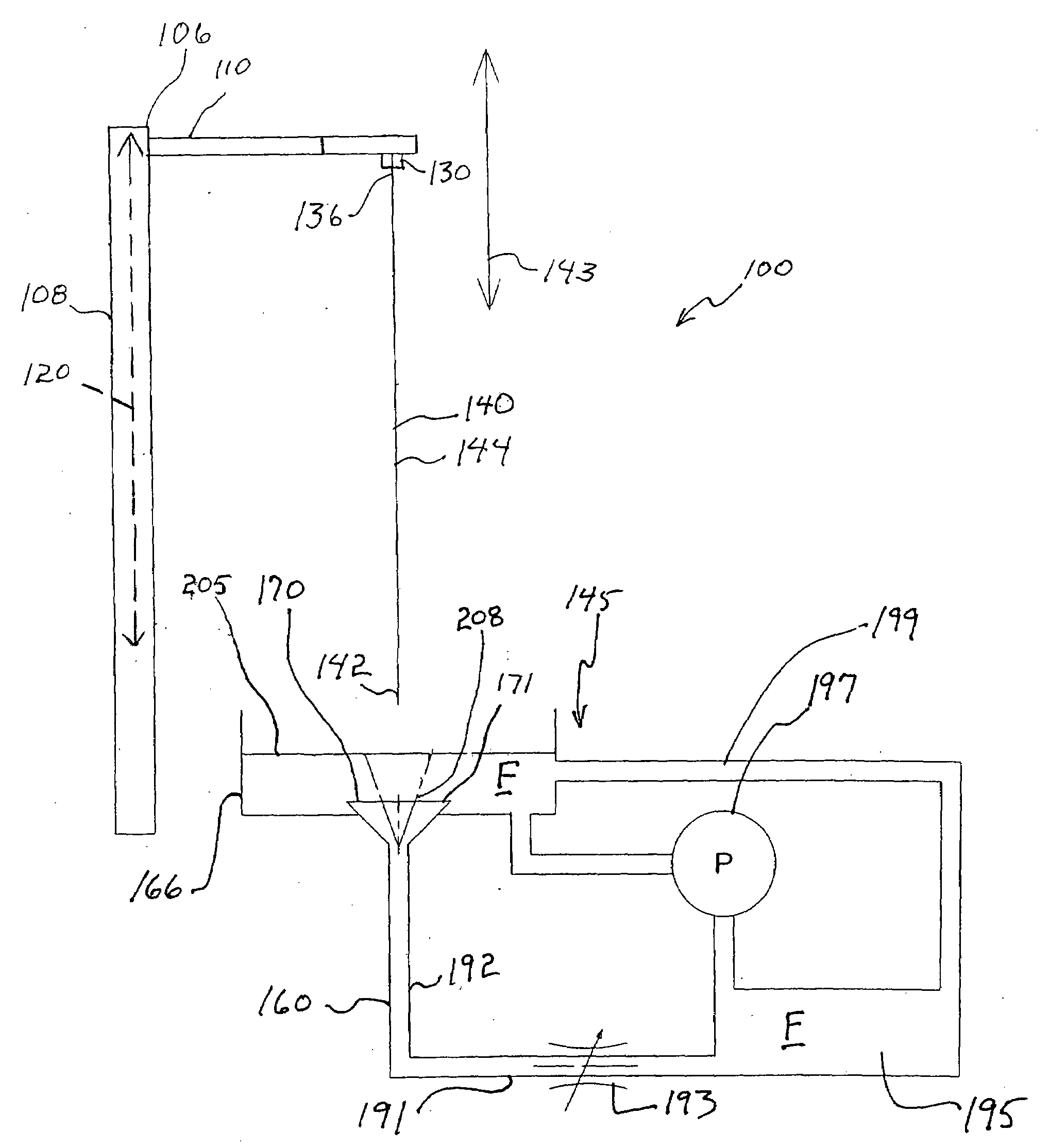

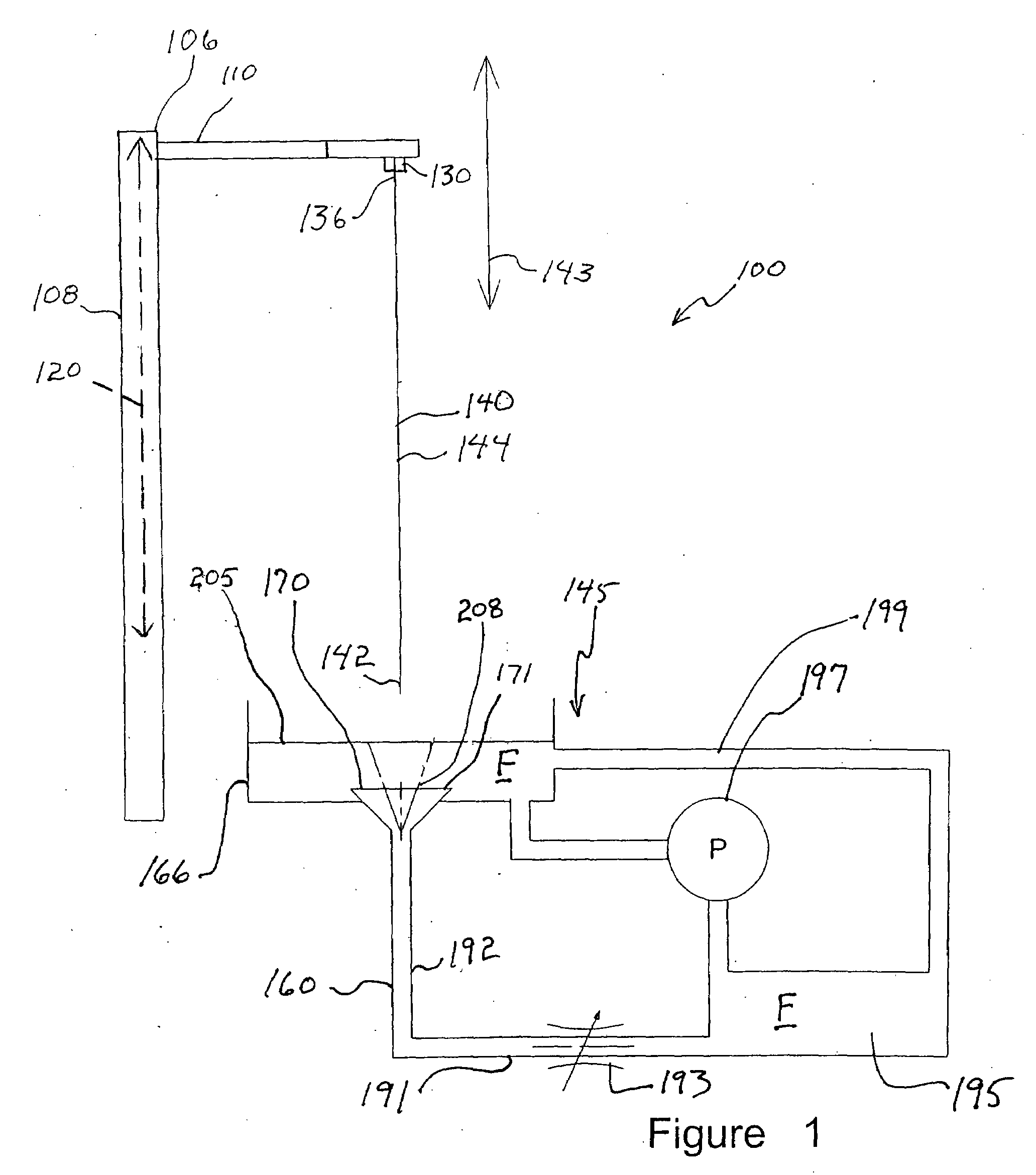

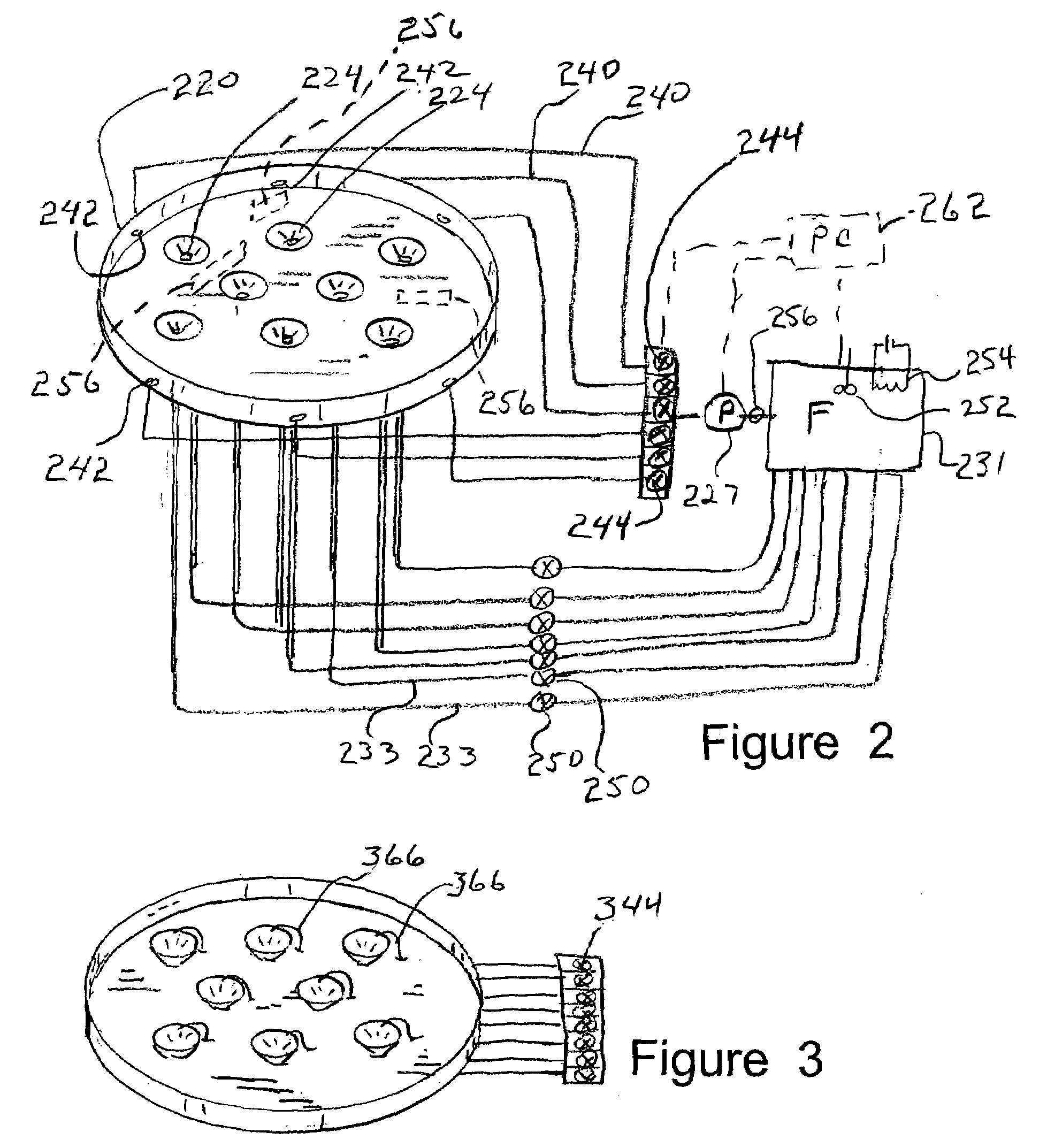

Device and Method for Manipulating and Inserting Electrode Arrays into Neural Tissues

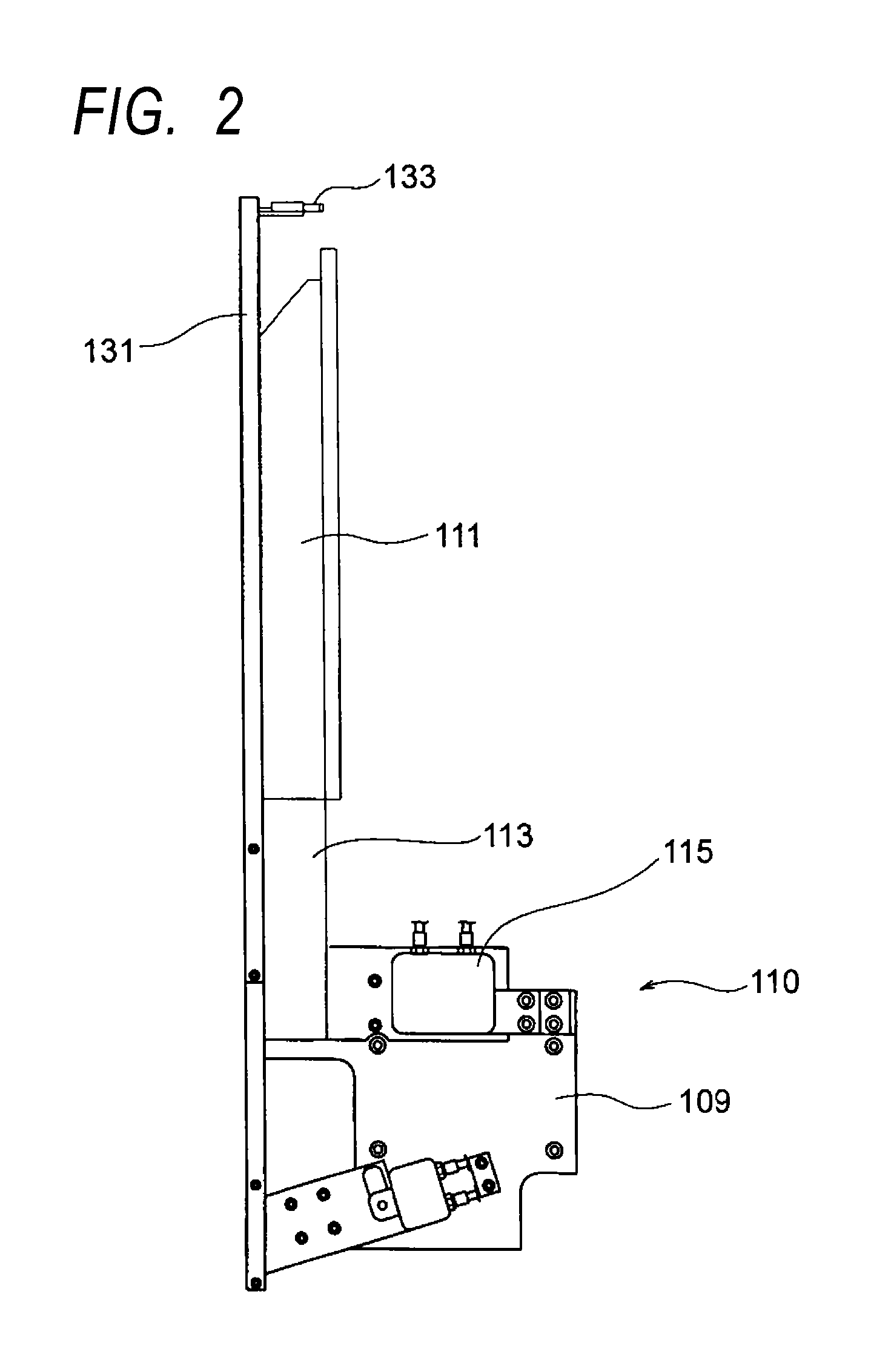

ActiveUS20080221589A1Improve insertion speedMinimize timeSpinal electrodesHead electrodesVacuum pressurePositive pressure

An insertion device for inserting a therapeutic device into organic tissue is disclosed and described. The device is particularly suited to insertion of such as nerve stimulating electrode arrays. The insertion device has at least one controllable positive pressure source (greater than atomospheric), two vacuum sources and a dual vacuum pressure control system. The positive pressure and the dual vacuum pressure control systems are manipulated to allow the manipulation and insertion or retrieval of a therapeutic device. The insertion device can be spatially manipulated by hand, without requiring other equipment for positioning the insertion device.

Owner:UNIV OF UTAH RES FOUND

Device and method for manipulating and inserting electrode arrays into neural tissues

ActiveUS8226661B2Improve insertion speedMinimize timeSpinal electrodesHead electrodesVacuum pressureControl system

An insertion device for inserting a therapeutic device into organic tissue is disclosed and described. The device is particularly suited to insertion of such as nerve stimulating electrode arrays. The insertion device has at least one controllable positive pressure source (greater than atomospheric), two vacuum sources and a dual vacuum pressure control system. The positive pressure and the dual vacuum pressure control systems are manipulated to allow the manipulation and insertion or retrieval of a therapeutic device. The insertion device can be spatially manipulated by hand, without requiring other equipment for positioning the insertion device.

Owner:UNIV OF UTAH RES FOUND

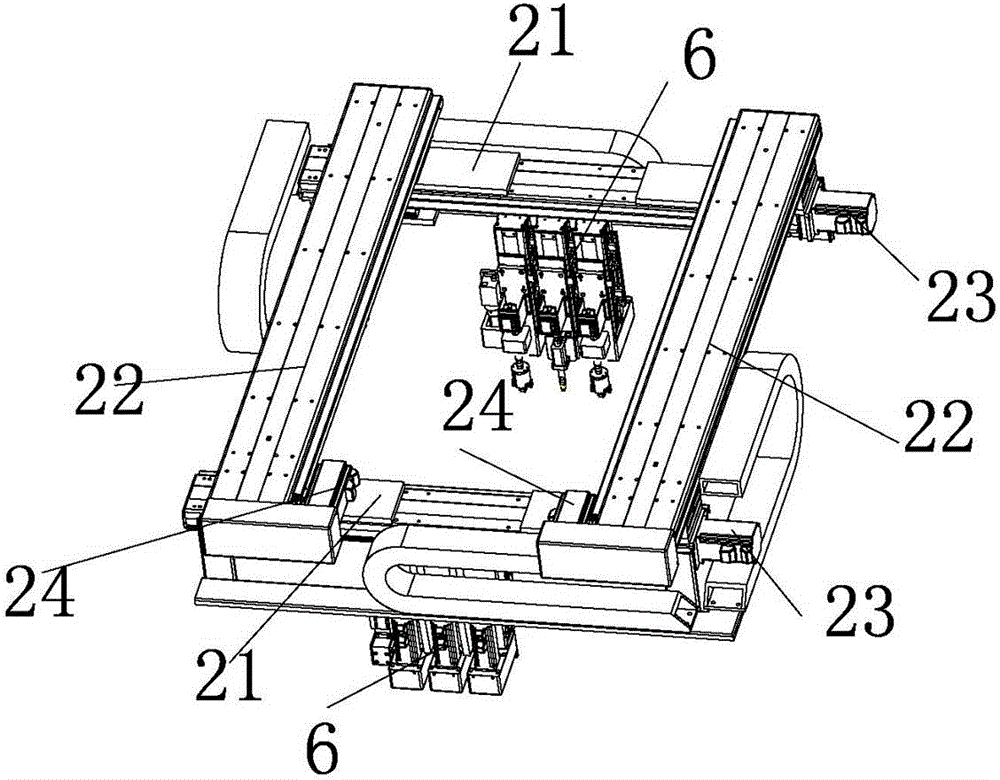

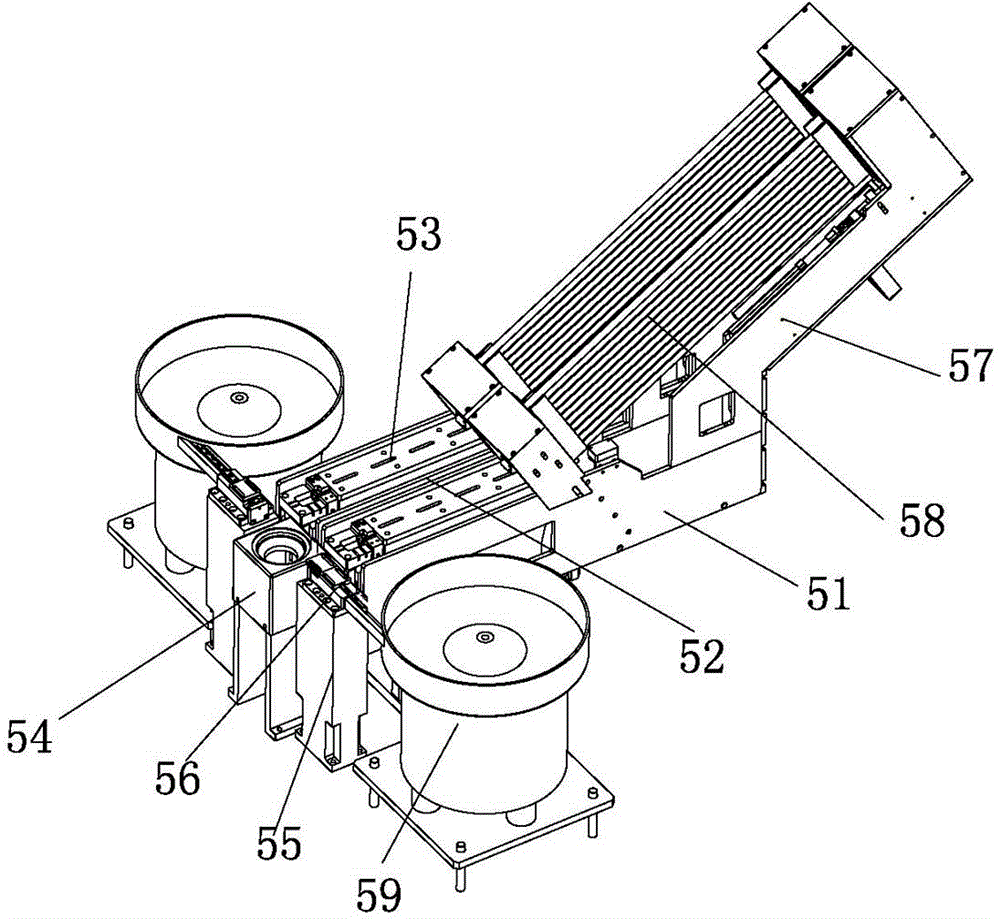

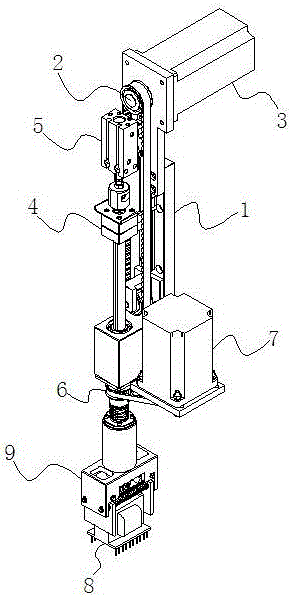

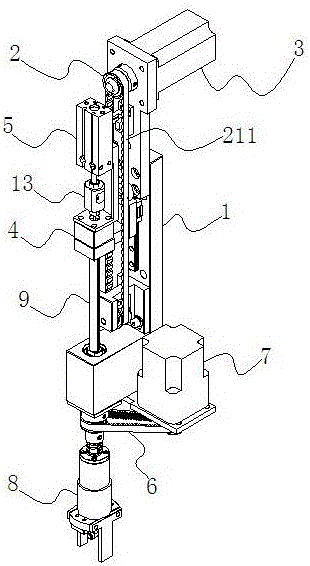

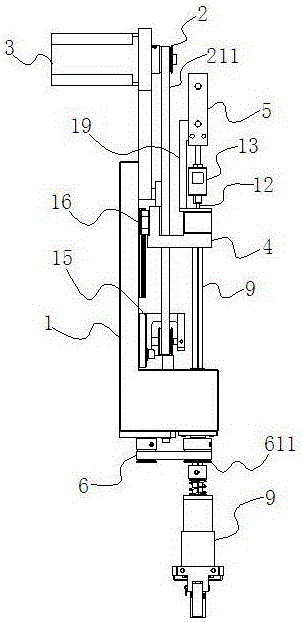

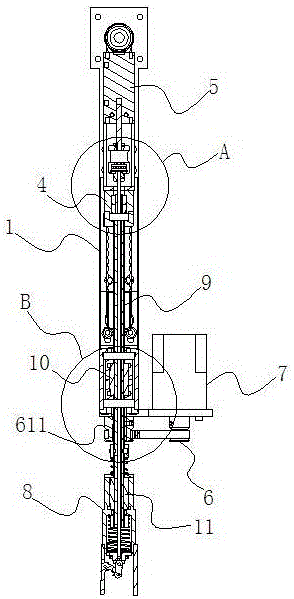

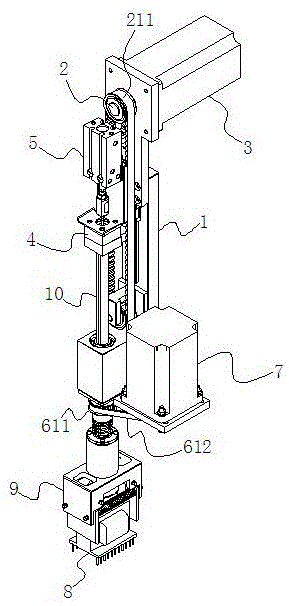

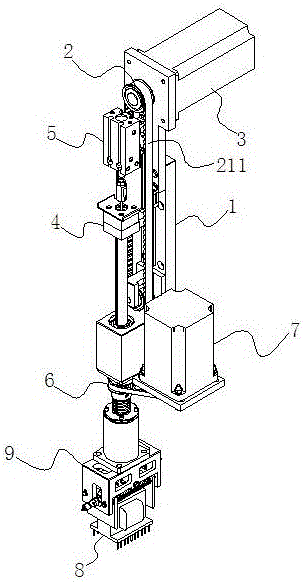

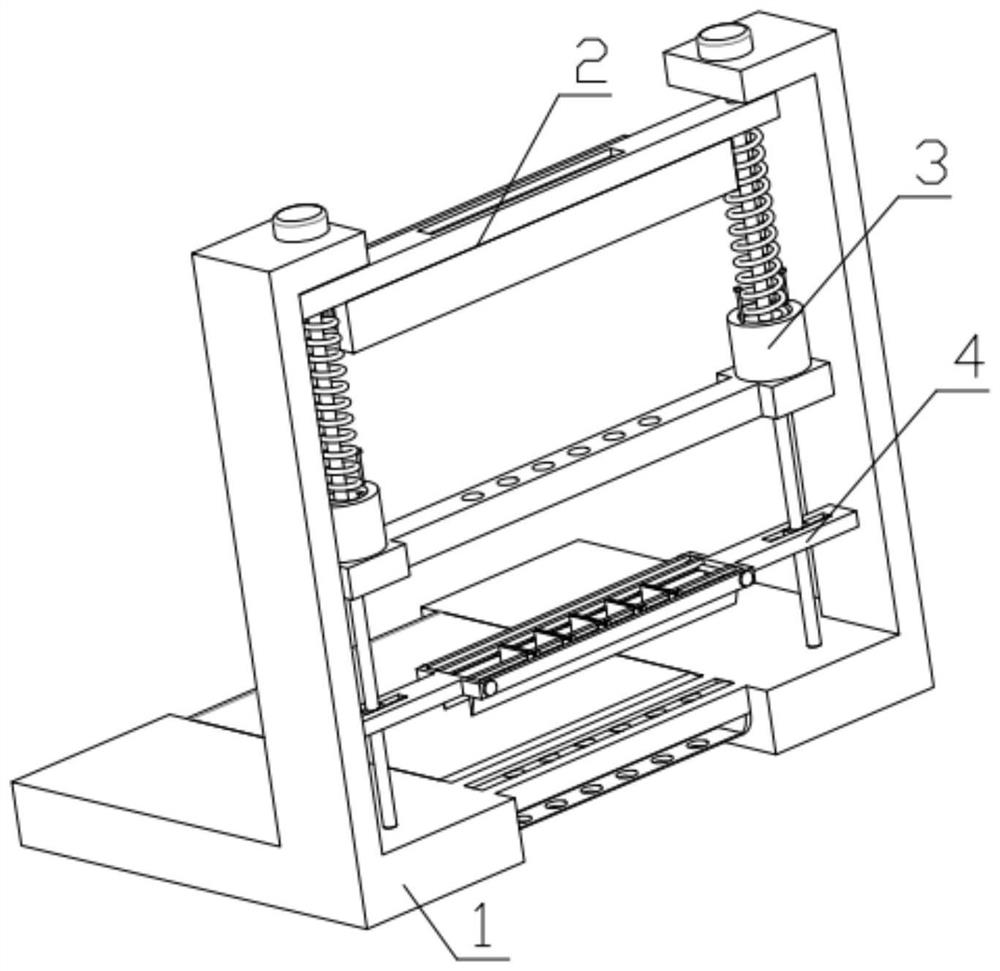

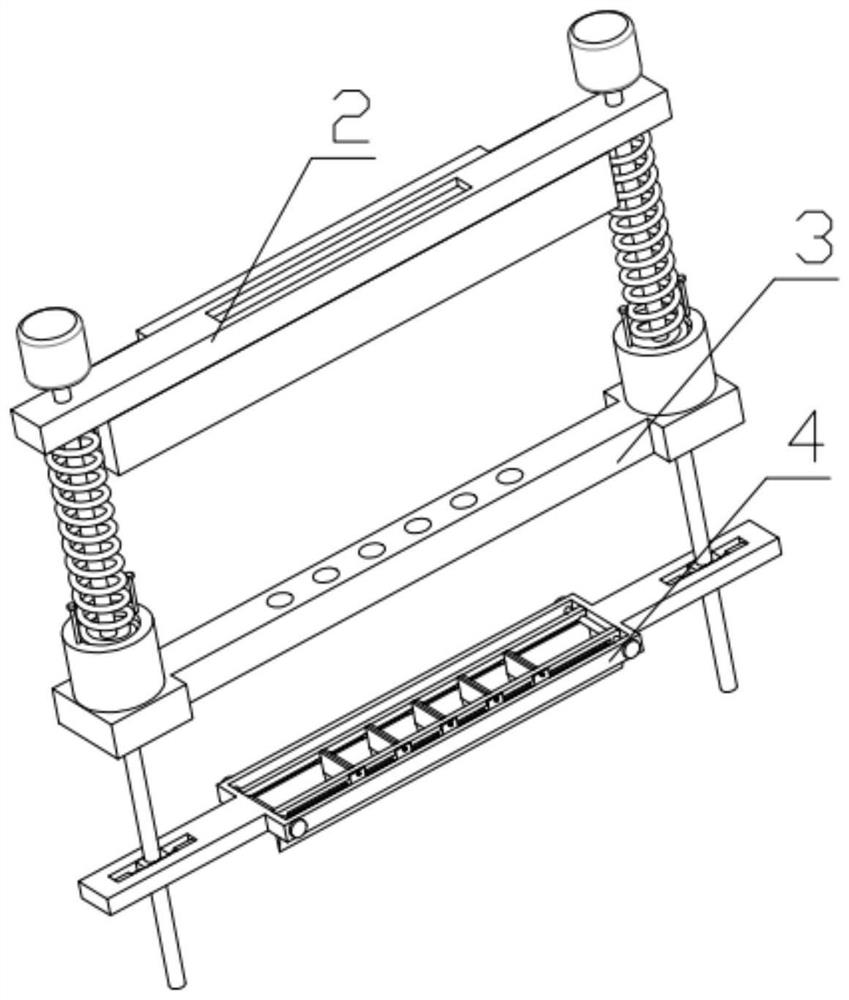

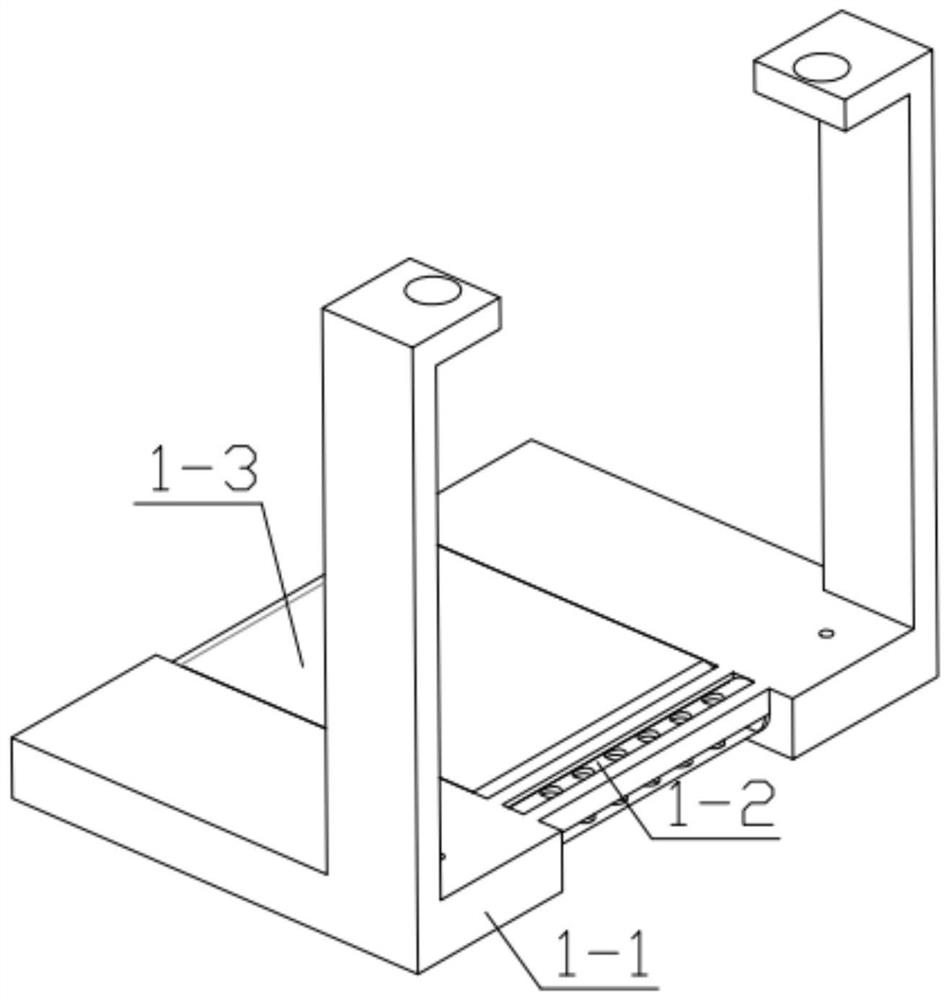

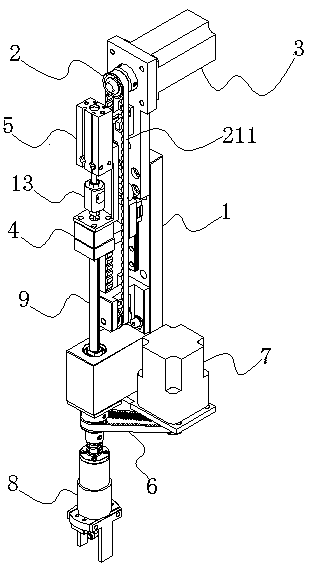

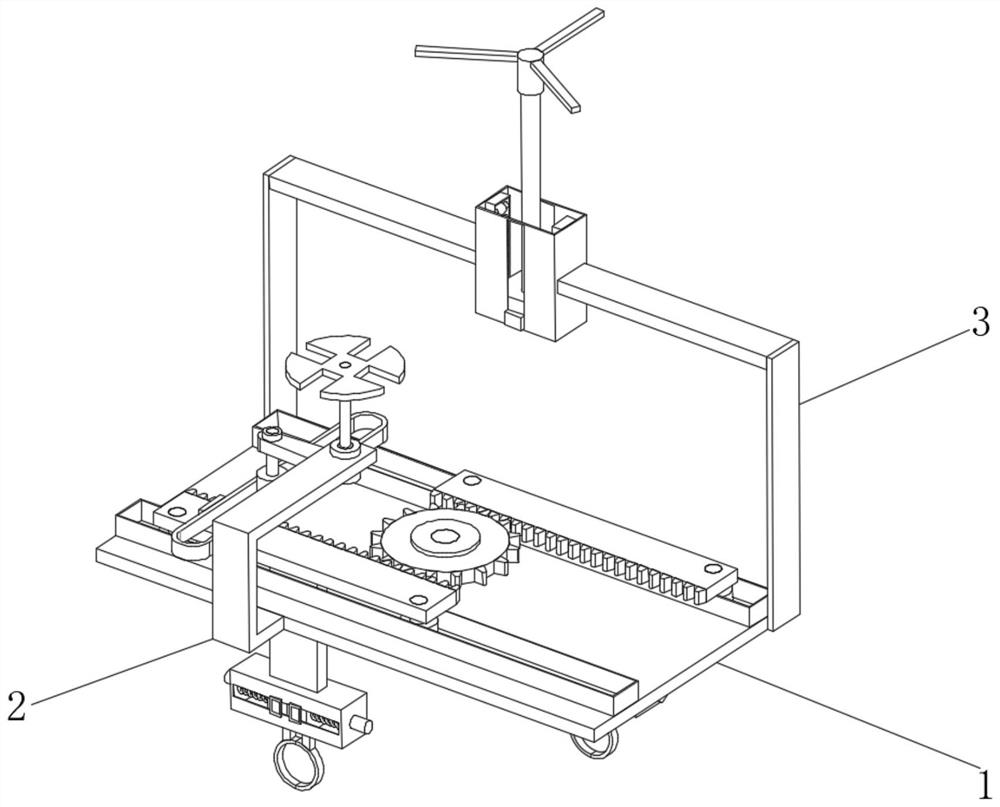

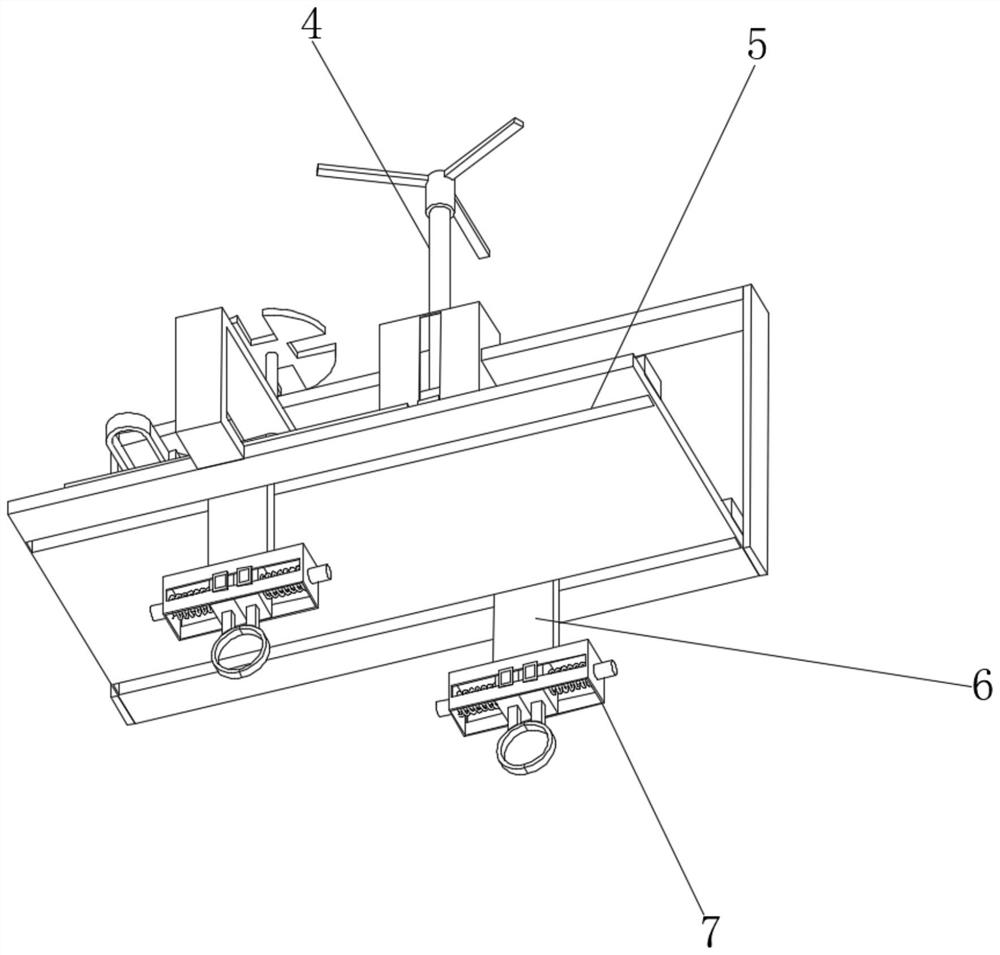

Double-work-head special-shaped insertion machine

PendingCN104582303AFetching is cheapSave round trip timePrinted circuit assemblingElectrical componentsEngineeringElectronic assemblies

The invention discloses a double-work-head special-shaped insertion machine which comprises a machine frame. The machine frame is provided with a transport support used for installation of a transport device with multiple work heads. A PCB conveyance locating device is arranged in the middle of the upper end of the machine frame, and the two sides of the upper end of the machine frame are each provided with a feeding device used for conveying electronic elements to the PCB conveyance locating device. The transport device transports and inserts the electronic elements conveyed by the two feeding devices into PCBs conveyed by the PCB transport locating device. Two work heads are adopted to take materials and insert the materials alternatively, so that the back-and-forth material taking time (about 1 second) of the work heads is saved, the insertion machine is in a working state to insert elements all the time, and therefore the inserting speed of the insertion machine is greatly increased (theoretically, the inserting speed is 1 time higher than that of an insertion machine with a single head). According to the insertion machine, each work head is provided with multiple insertion mechanical arms, the insertion machine is compatible with different special-shaped elements, and the assembly requirement for special-shaped elements of an electronic assembly market can be met.

Owner:KELI ELECTRONICS EQUIP

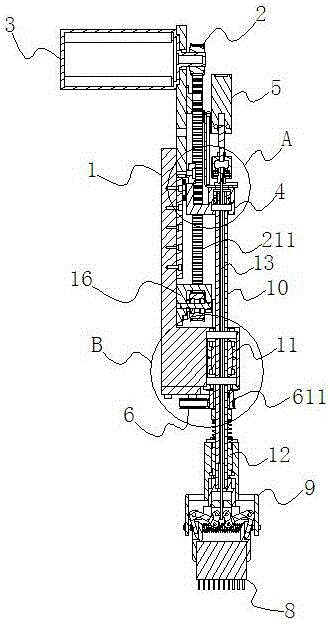

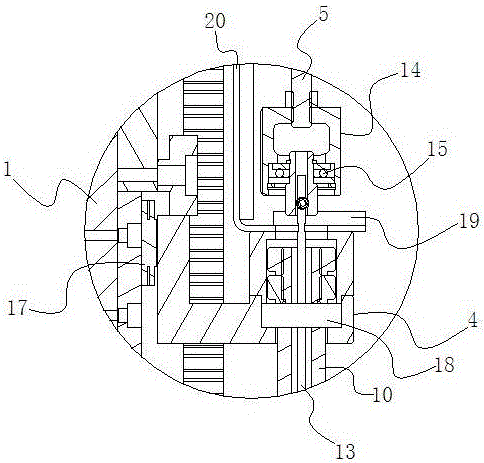

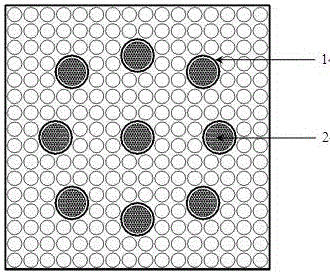

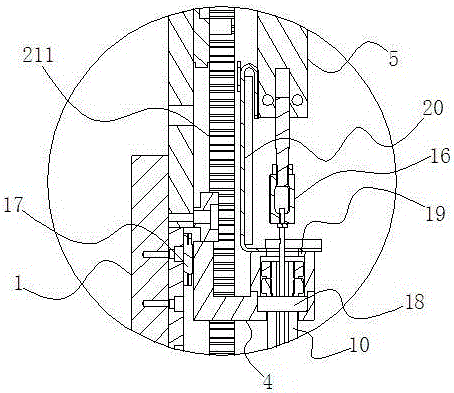

Parallel clamping-type large electronic element pasting and inserting operation head and pasting and inserting method thereof

InactiveCN105744754AFast and accurate insertionImprove insertion speedPrinted circuit assemblingElectrical componentsDrive wheelThrust bearing

The invention discloses a parallel clamping-type large electronic element pasting and inserting operation head and a pasting and inserting method thereof. The pasting and inserting operation head comprises a pasting and inserting support seat, a synchronous belt device I, a control motor I, an L-shaped slide block, a clamping air cylinder, a synchronous belt device II, a control motor II, a parallel clamping-type chuck, a spline shaft, a spline shaft sleeve I, a spline shaft sleeve II, a draw bar, a draw bar connection sleeve and a thrust bearing, wherein the parallel clamping-type chuck can be controlled to be in a clamping state or a loosening state through the draw bar; the synchronous belt device I can drive the L-shaped slide block, the clamping air cylinder, the draw bar and the parallel clamping-type chuck to move up and down along the vertical direction through rotation of the control motor I; a driven wheel II of the synchronous belt device II is fixedly connected to the outer peripheral surface of the spline shaft sleeve I; and the driven wheel II, the spline shaft sleeve I, the spline shaft, the spline shaft sleeve II, the parallel clamping-type chuck, the draw bar and an upper ring of the thrust bearing can be driven to rotate around the axis of the spline shaft in the horizontal direction through rotation of the control motor II.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

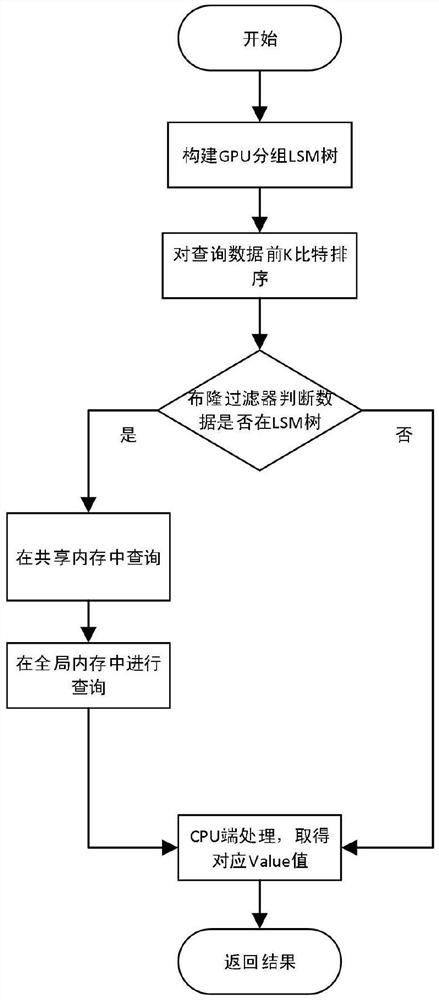

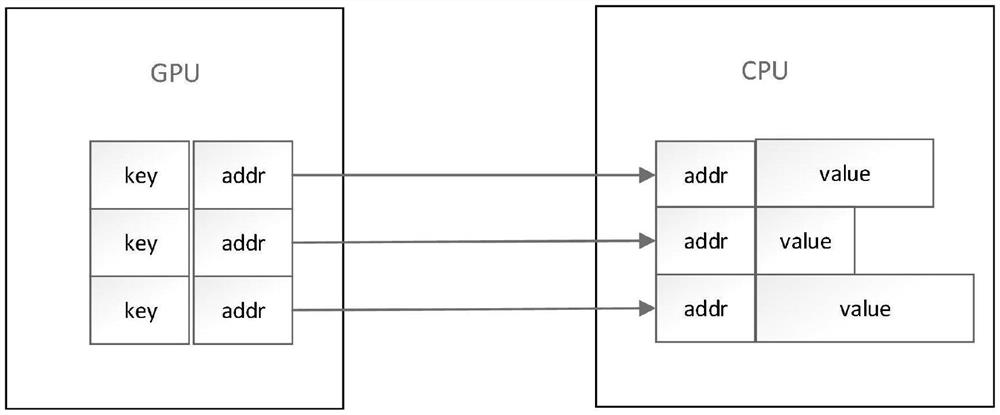

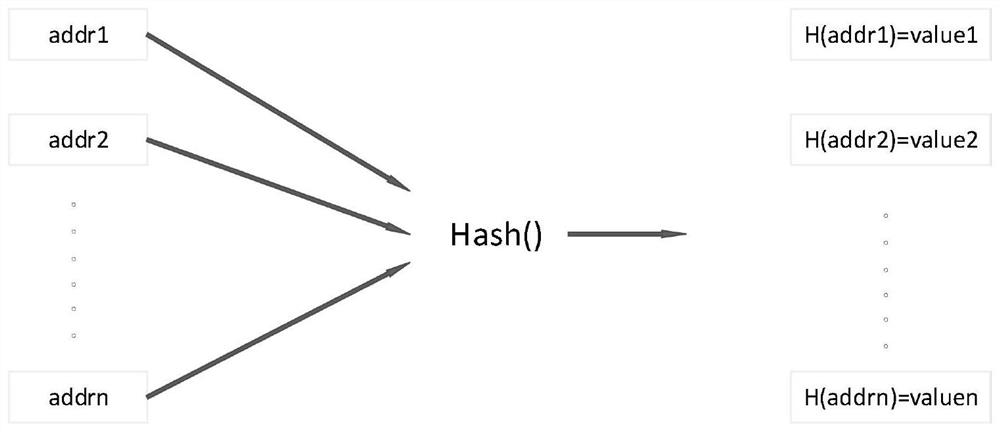

Method for grouping LSM tree indexes based on GPU

ActiveCN112000846AImprove insertion speedImprove query speedOther databases indexingOther databases queryingComputational scienceParallel computing

The invention provides a grouping LSM tree indexing method based on a GPU, and relates to the technical field of GPU databases. According to the method, firstly, data is preprocessed, when value is lengthened, cache cannot be well utilized when query is carried out on a GPU, and the data transmission cost can be increased. Aiming at the conditions, the Key and the Value in the data are separated,only the address of the Value is stored in the GPU, and the real Value is stored in the memory. Aiming at the problem of low LSM insertion speed, each layer of an original LSM tree is divided into a plurality of groups, each group is an ordered array, and parallel merging is performed through a large number of threads on a GPU when the groups are merged to the next layer. Because the LSM trees aregrouped, the query needs to spend a higher cost. In order to improve the query speed, a Bloom filter suitable for a GPU structure is designed on the GPU, and a large amount of unnecessary query expenditure is reduced through the Bloom filter.

Owner:NORTHEASTERN UNIV

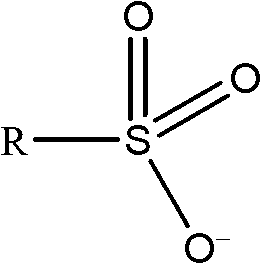

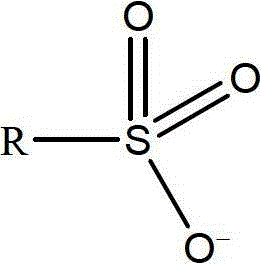

Vanadium catalyst and preparation method of vanadium catalyst as well as preparation method of ethylene-propylene copolymer

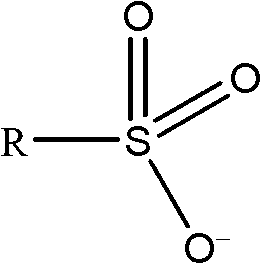

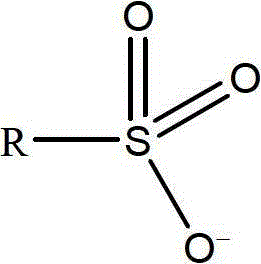

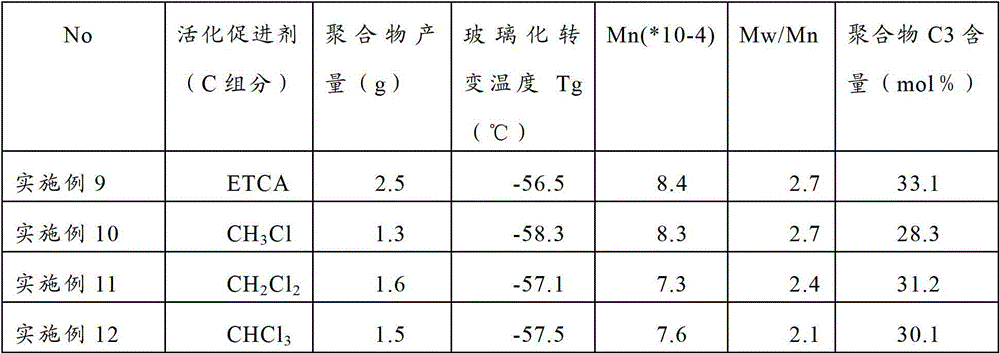

The invention provides a vanadium catalyst with a general formula of VO(RSO3)mCln.xR'OH, wherein m+n=3, and m is 1, 2 or 3, n is 0, 1 or 2; x is within 1-3.5; RSO3<-> has a structure shown in formula I; R is a C1-C20 linear or branched alkyl, aryl, aralkyl or halogen-substituted alkyl, halogen-substituted aryl, and halogen-substituted aralkyl; R'OH is straight chain aliphatic alcohol or branched chain aliphatic alcohol with carbon atom number of 5-10. The vanadium catalyst provided by the invention has the advantages of high activity and low cost. The invention also provides a preparation method of the catalyst and a preparation method of binary or ternary ethylene-propylene copolymer by using the catalyst. The following formula is the formula I.

Owner:中科应化(长春)科技有限公司

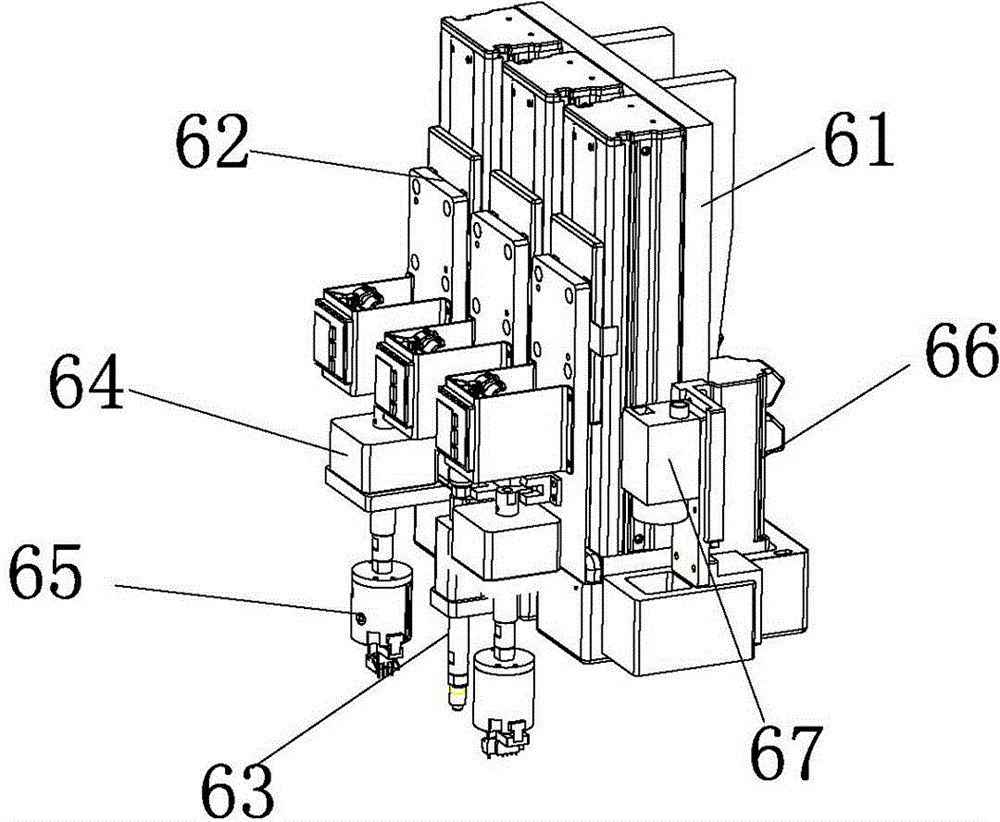

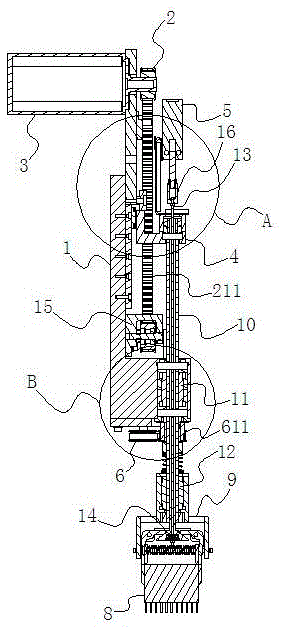

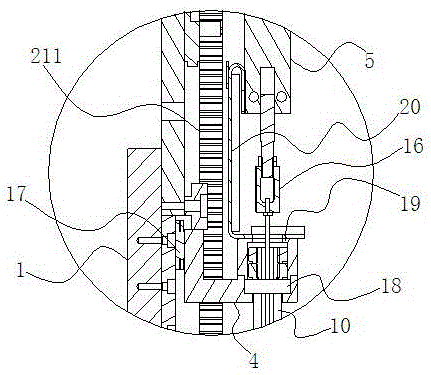

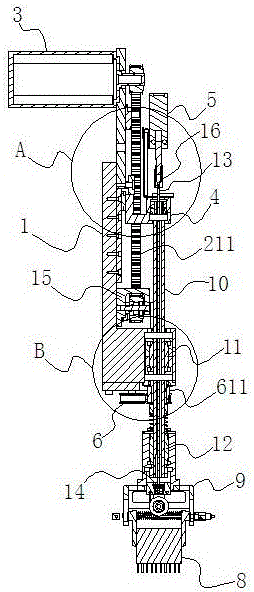

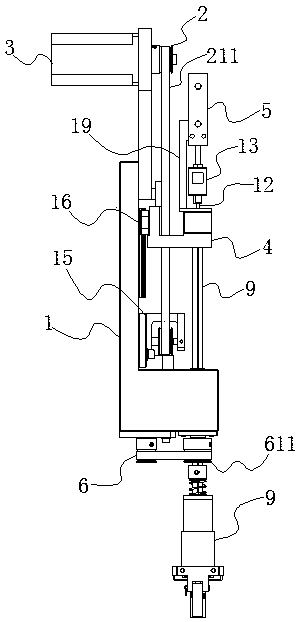

Insertion operating head of middle-sized electronic component and insertion method of insertion operating head

InactiveCN105744755AFast and accurate insertionImprove insertion speedPrinted circuit assemblingElectrical componentsThrust bearingEngineering

The invention discloses an insertion operating head of a middle-sized electronic component and an insertion method of the insertion operating head. The insertion operating head comprises an insertion head support, a first synchronous belt device, a first control motor, an L-shaped sliding block, a clamping air cylinder, a second synchronous belt device, a second control motor, a single-side movable clamping claw type clamping head, a spline shaft, a first spline shaft sleeve, a second spline shaft sleeve, a pull rod, a pull rod connection sleeve and a thrust bearing, wherein under the action of the clamping air cylinder, the single-side movable claw type clamping head can be controlled to be a clamping or loosen state by the pull rod; under the rotation of the first control motor, the first synchronous belt can drive the L-shaped sliding block, the clamping air cylinder, the spline shaft and the single-side movable claw type clamping head to vertically move upwards and downwards; a second driven pulley of the second synchronous belt device is fixedly connected with the outer peripheral surface of the first spline shaft sleeve; and through the rotation of the second control motor, the second driven pulley, the first spline shaft sleeve, the spline shaft, the second spline shaft sleeve, the single-side movable claw type clamping head, the pull rod and an upper ring of the thrust bearing can be driven to rotate around the axial line of the spline shaft in a horizontal direction.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Large-scale electronic element attaching-inserting joint and attaching-inserting method therefor

InactiveCN105611748AFast and accurate insertionImprove insertion speedPrinted circuit assemblingDrive wheelThrust bearing

The invention discloses a large-scale electronic element attaching-inserting joint and an attaching-inserting method therefor. The attaching-inserting joint comprises an attaching-inserting joint supporting base, a synchronous band apparatus I, a control motor I, an L-shaped sliding block, a clamping air cylinder, a synchronous band apparatus II, a control motor II, a chuck, a spline shaft, a spline shaft sleeve I, a spline shaft sleeve II, a pull rod and a thrust bearing; under the action of the clamping air cylinder, the chuck can be controlled to be in a clamped state or in a loosened state through the chuck so as to clamp or loosen the large-scale electronic element by the chuck; by controlling the rotation of the motor I, the synchronous band apparatus I can drive the L-shaped sliding block to move up and down in a perpendicular direction so as to drive the clamping air cylinder, the pull rod, the spline shaft, the spline shaft sleeve II and the chuck to move together; a driven wheel II of the synchronous band apparatus II is fixedly connected with the outer peripheral surface of the spline shaft sleeve I; by controlling the rotation of the control motor II, the driven wheel II can be driven to rotate so as to drive the spline shaft sleeve I, the spline shaft, the spline shaft sleeve II and the chuck to rotate in a horizontal direction around the axial line of the spline shaft to realize control for the rotating angle of the chuck.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

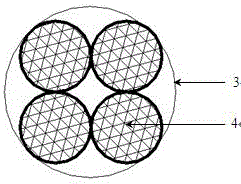

Bundle-like control rod structure

ActiveCN106297907AImprove economyImprove securityNuclear energy generationReactor fuel elementsNuclear engineeringControl rod

The invention discloses a bundle-like control rod structure applied to a small reactor. The bundle-like control rod structure comprises a bundle-like control rod consisting of multiple sub control rods, the bundle-like control rod is sleeved with multiple binding rings for fixing the sub control rods, and technical effects that the reactivity control capacity is improved, reactivity punishment of burnable poison rods at the end of the service life is reduced and the economy and safety of the small reactor are improved are realized.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

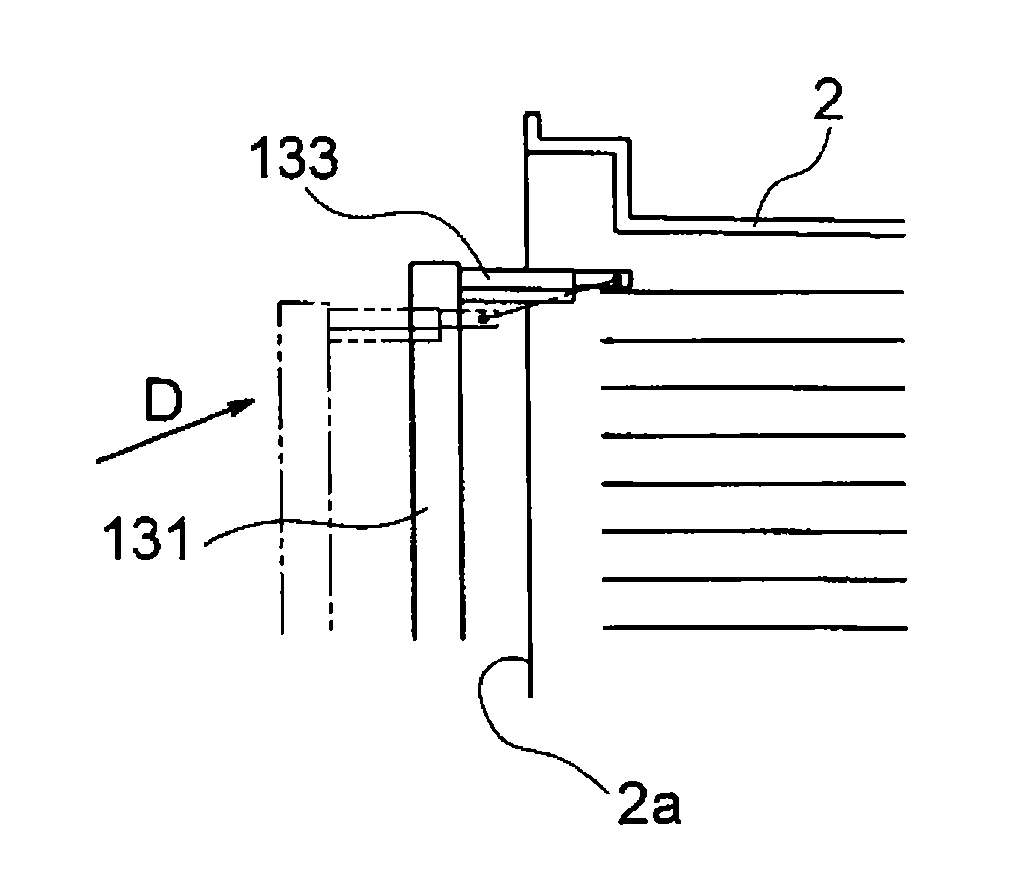

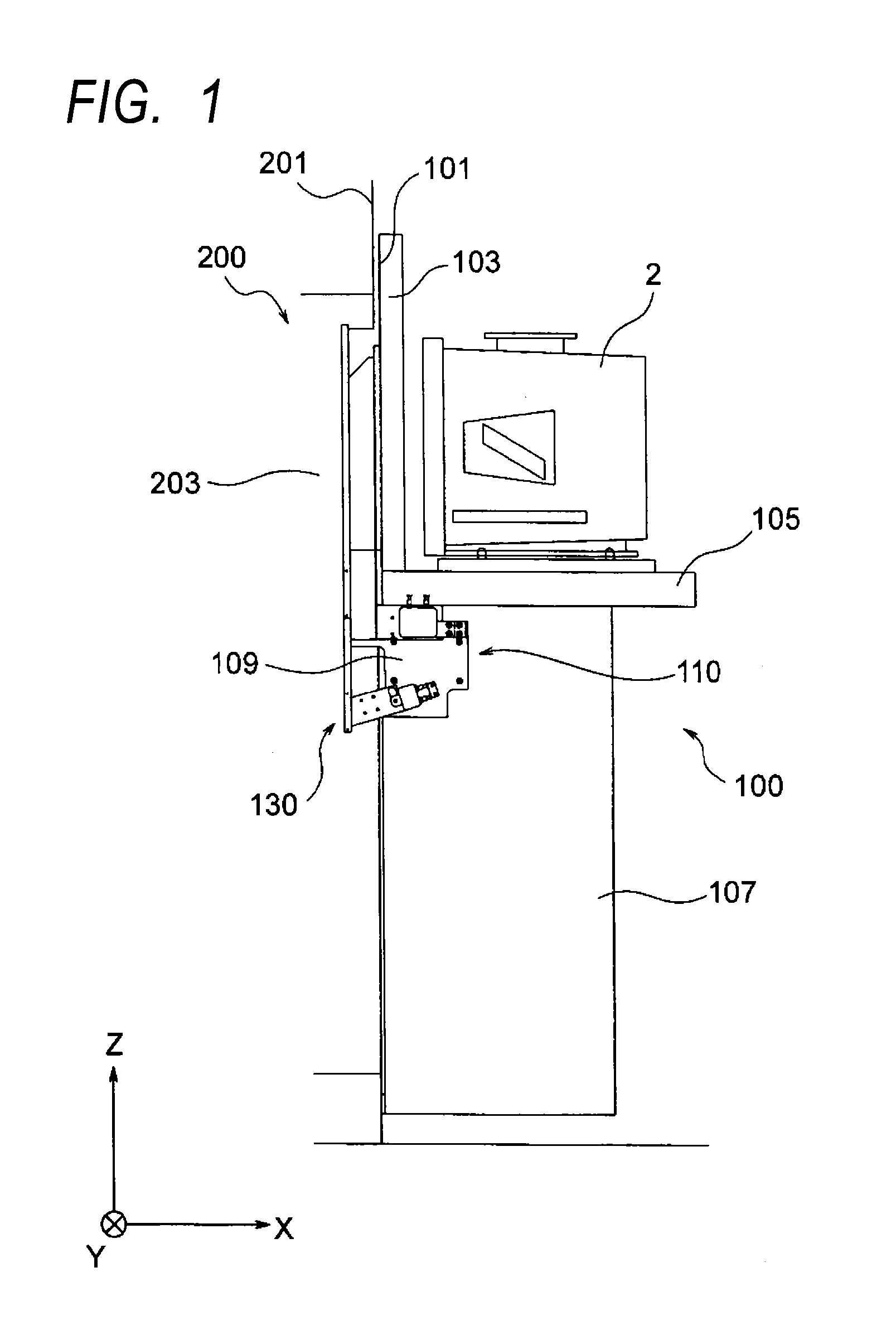

Load port apparatus and method of detecting object to be processed

ActiveUS20130074615A1High speedAvoid contactSemiconductor/solid-state device manufacturingUsing mechanical meansAcute angleMechanical engineering

To enable appropriate wafer mapping in the case where a wafer is stored at the highest level, which is provided as a reserve, of a pod, a load port apparatus drives a mapping frame that supports a sensor by a first driving unit that drives the mapping frame in a first direction parallel to the direction along which wafers in the pod are arranged in an overlapping manner and a second driving unit that drives the mapping frame in a second direction that crosses the first direction in such a way as to form an acute angle in the side in which the sensor starts the mapping.

Owner:TDK CORPARATION

Inserting method based on tree-shaped data structure node and storing device

ActiveCN101515298BLower the altitudeReduce insertion timeDigital data information retrievalKnowledge representationArray data structureTheoretical computer science

A tree-based node insertion method and a memory device are disclosed in embodiments of the present invention. The tree-based node insertion method includes: according to the key value of a node to be inserted, searching in a primary tree for the nearest node whose key value is smaller than and the most approximate to the key value of the node to be inserted; judging whether the current secondary tree is full, and if so, selecting a node from the current secondary tree as a split node, transferring all the nodes on the right of the split node in the current secondary tree to the new secondary tree, and if not, inserting the node to be inserted into the current secondary tree.

Owner:HUAWEI TECH CO LTD

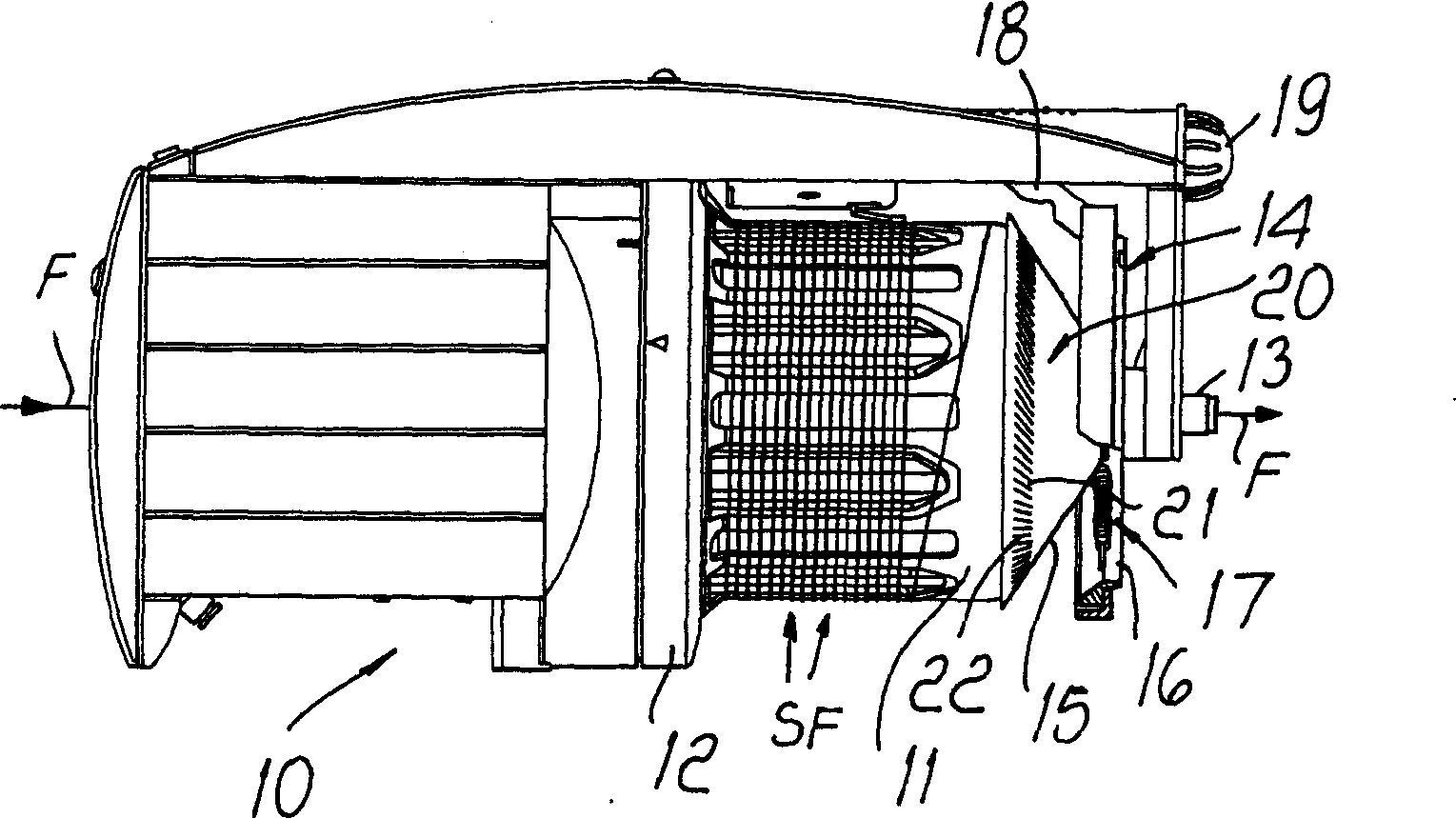

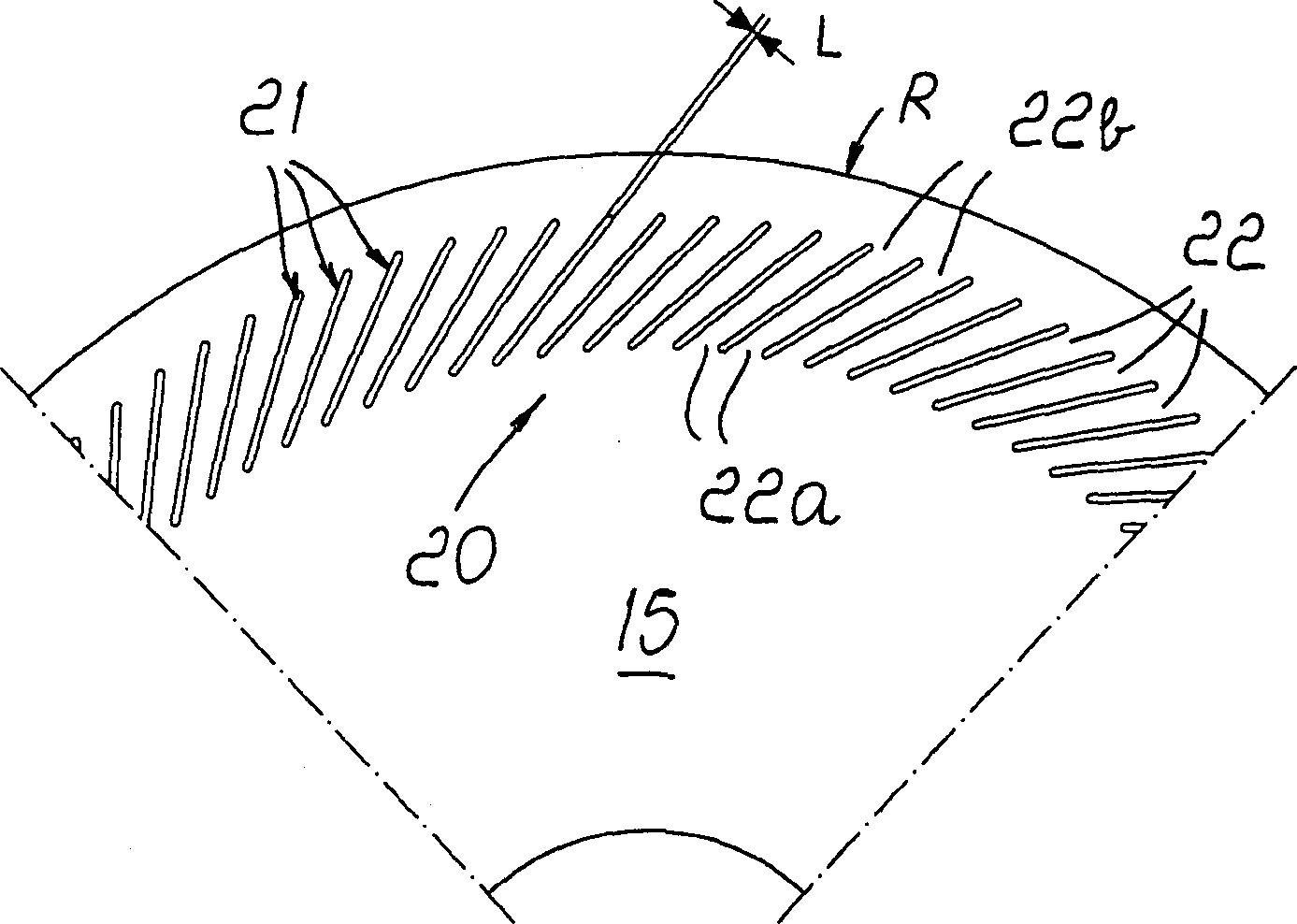

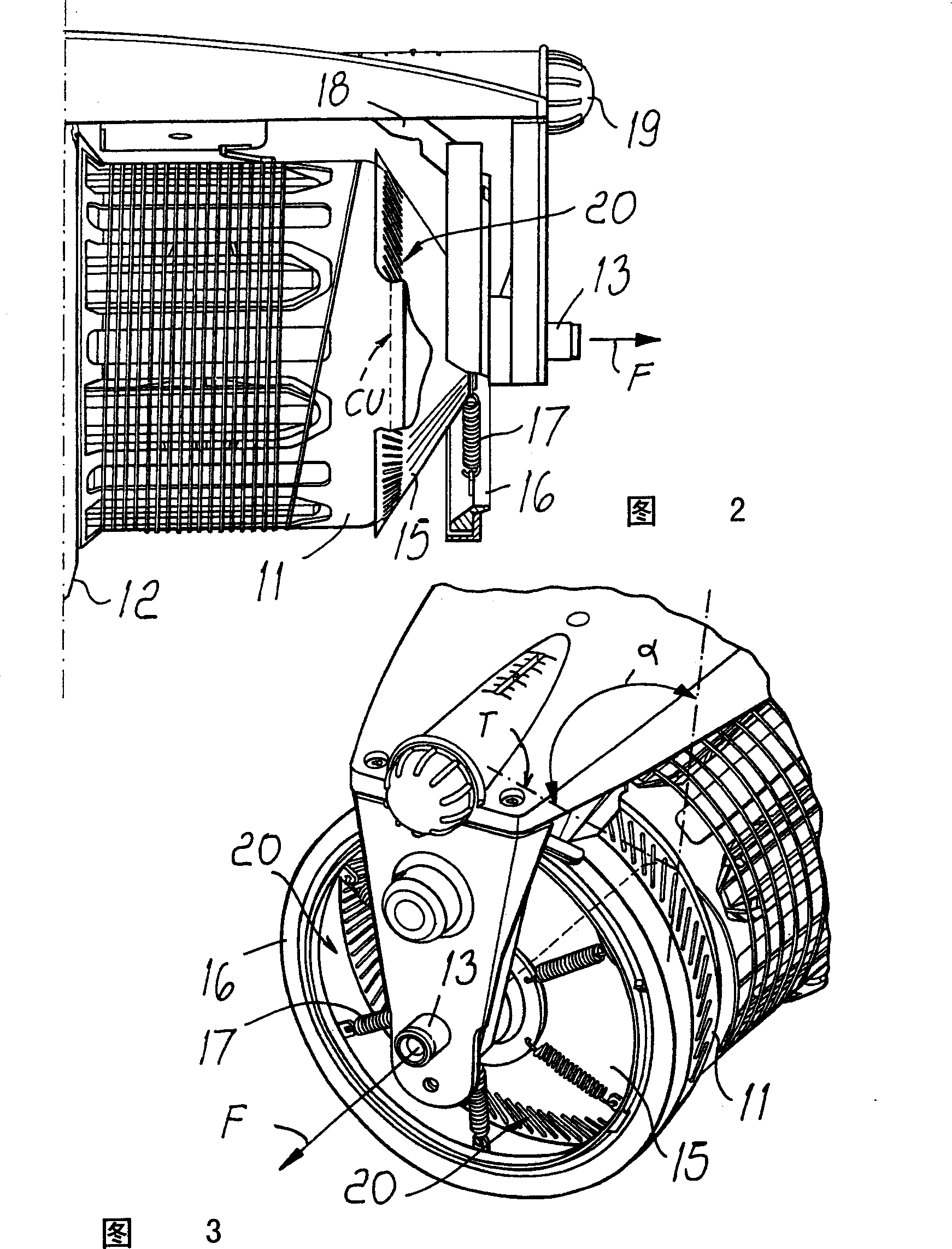

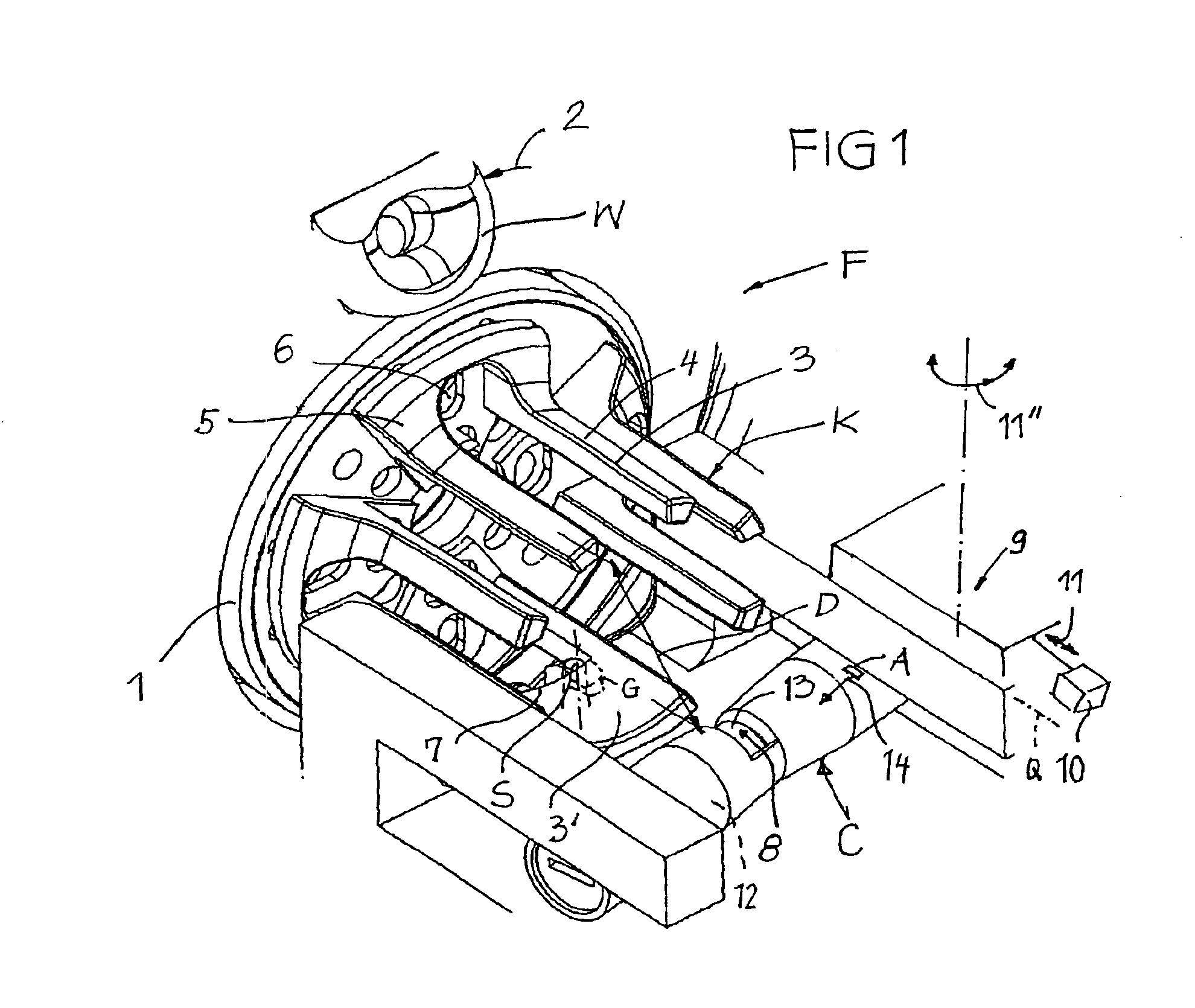

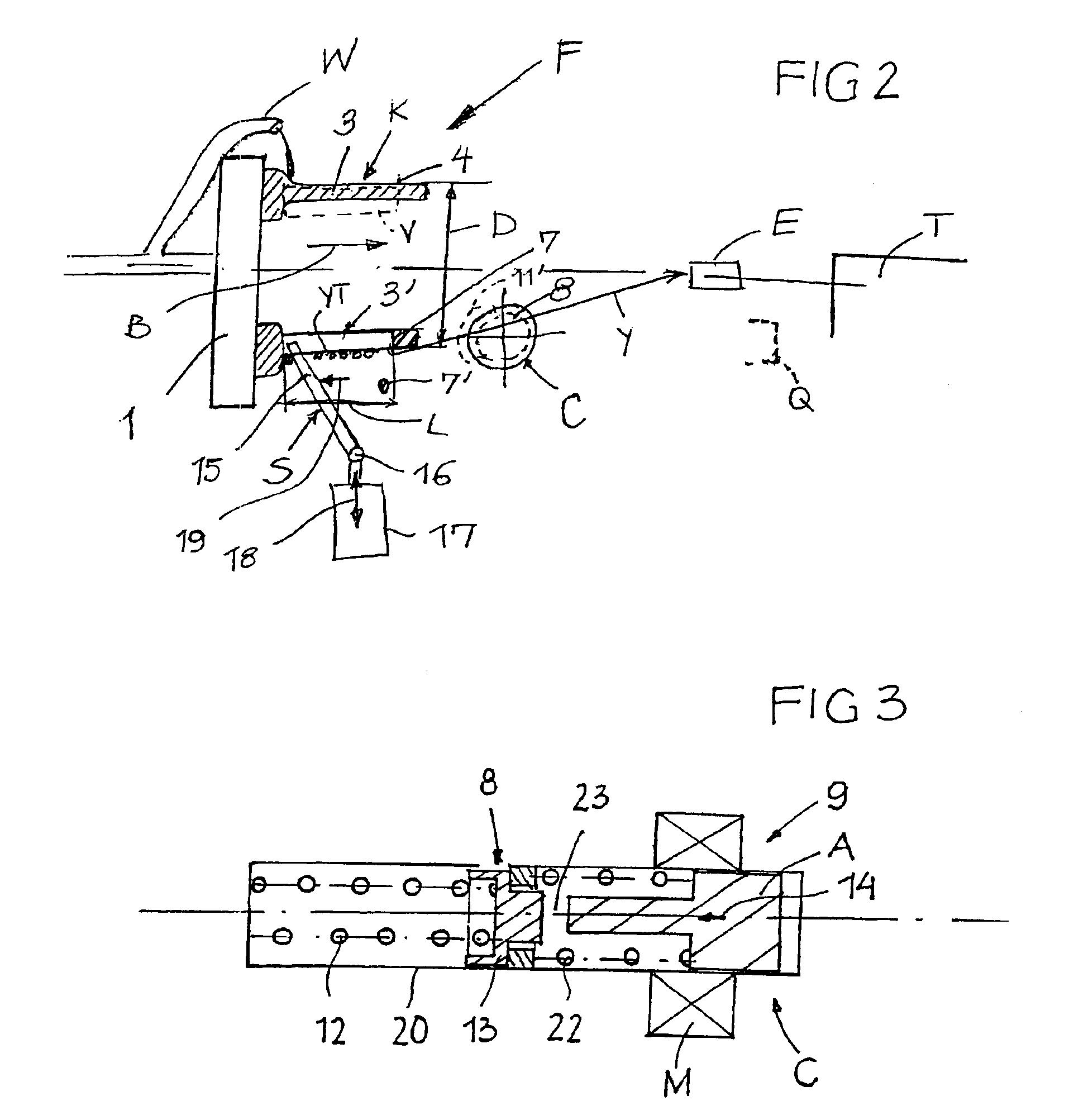

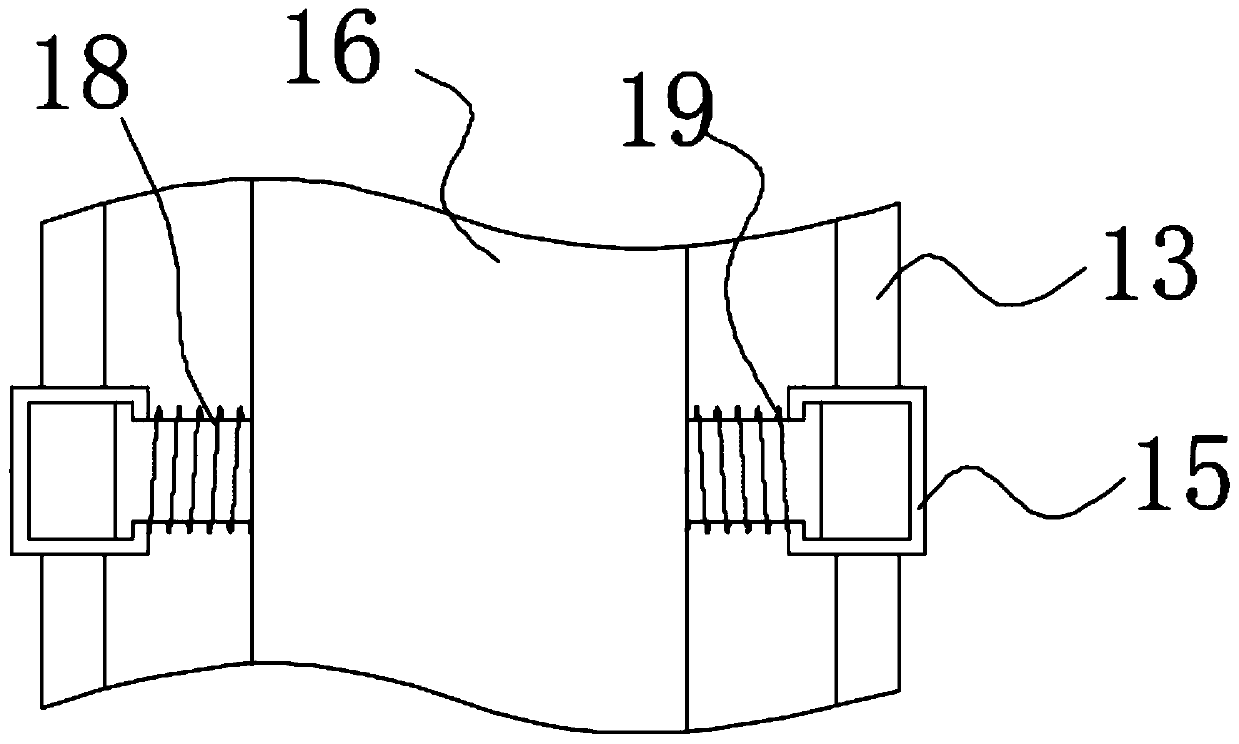

Self-regulating brake apparatus for weft-feeding device

A self-adjusting braking device for a weft feeder having a frusto-conical braking body (15) acting on said yarn and elastically suspended on the drum of the weft feeder ( 11) and is pushed into elastic tangential contact with the drum along the outer circumference (CU) of the drum's outlet end. The brake body (15) has a discontinuous annular contact element (20) at its larger diameter region (R) in contact with the drum (11), the annular contact element comprising a plurality of through slots (21), the through slots The grooves are arranged equidistant from each other and form a row of contact lamellas (22).

Owner:L G L ELECTRONICS

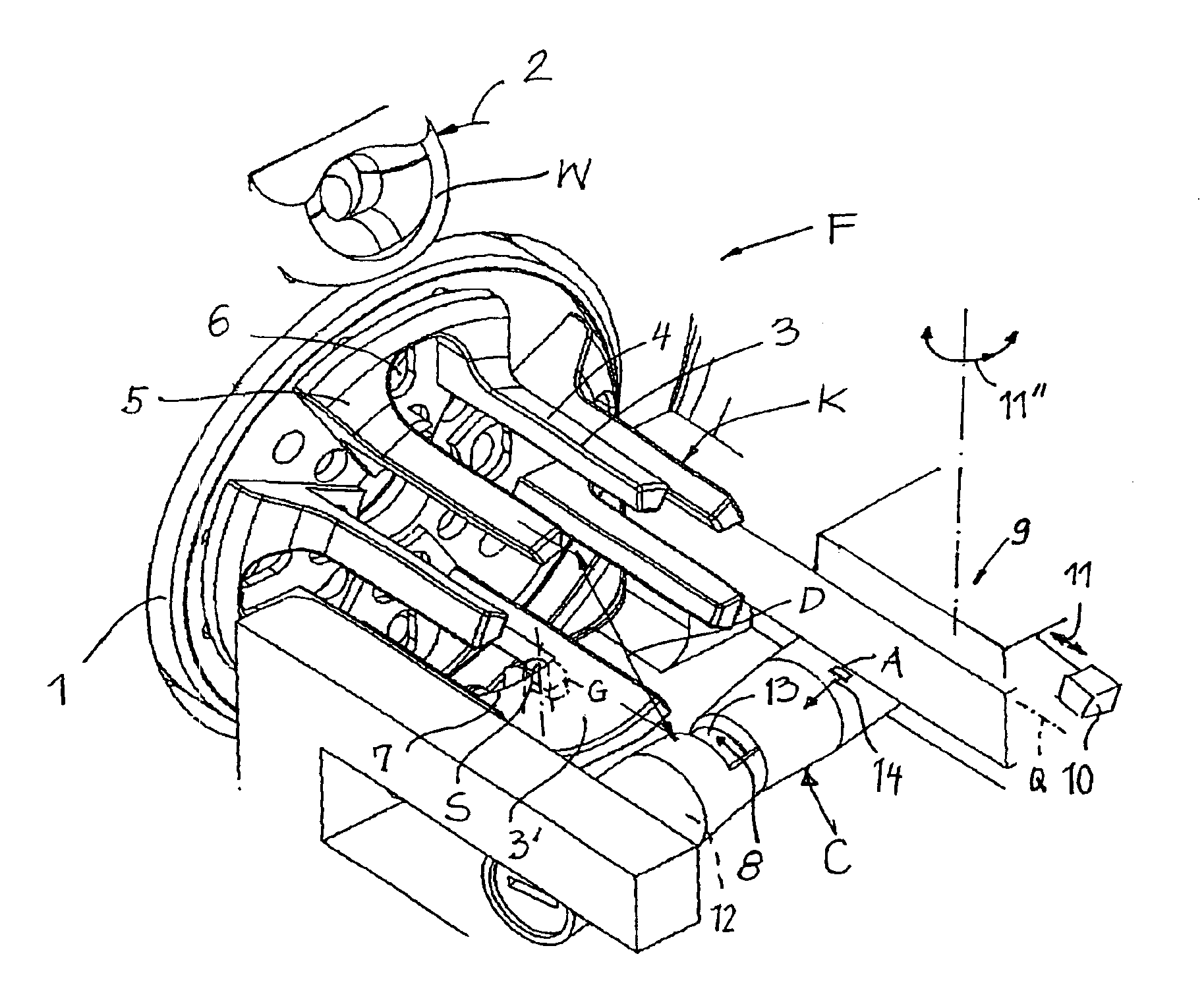

Feeding device

A feeding device for a mechanical weaving machine, including a winding element which can be driven in a rotating manner, a stationary storage, and at least one stop element. The stop element can be axially and radially moved in relation to the storage body, between an unwinding position releasing thread yarn and a stop position wherein the stop element is applied to the foremost winding and which ends the weft insertion. A yarn clamp is arranged downstream from the stop element, which initiates the respective weft insertion, and which can be switched between a passive position and a clamping position. The storage body has a small diameter, and the stop element is moved axially to the stop position solely by the windings due to a transport motion of the windings on the storage body.

Owner:IROPA AG (CH)

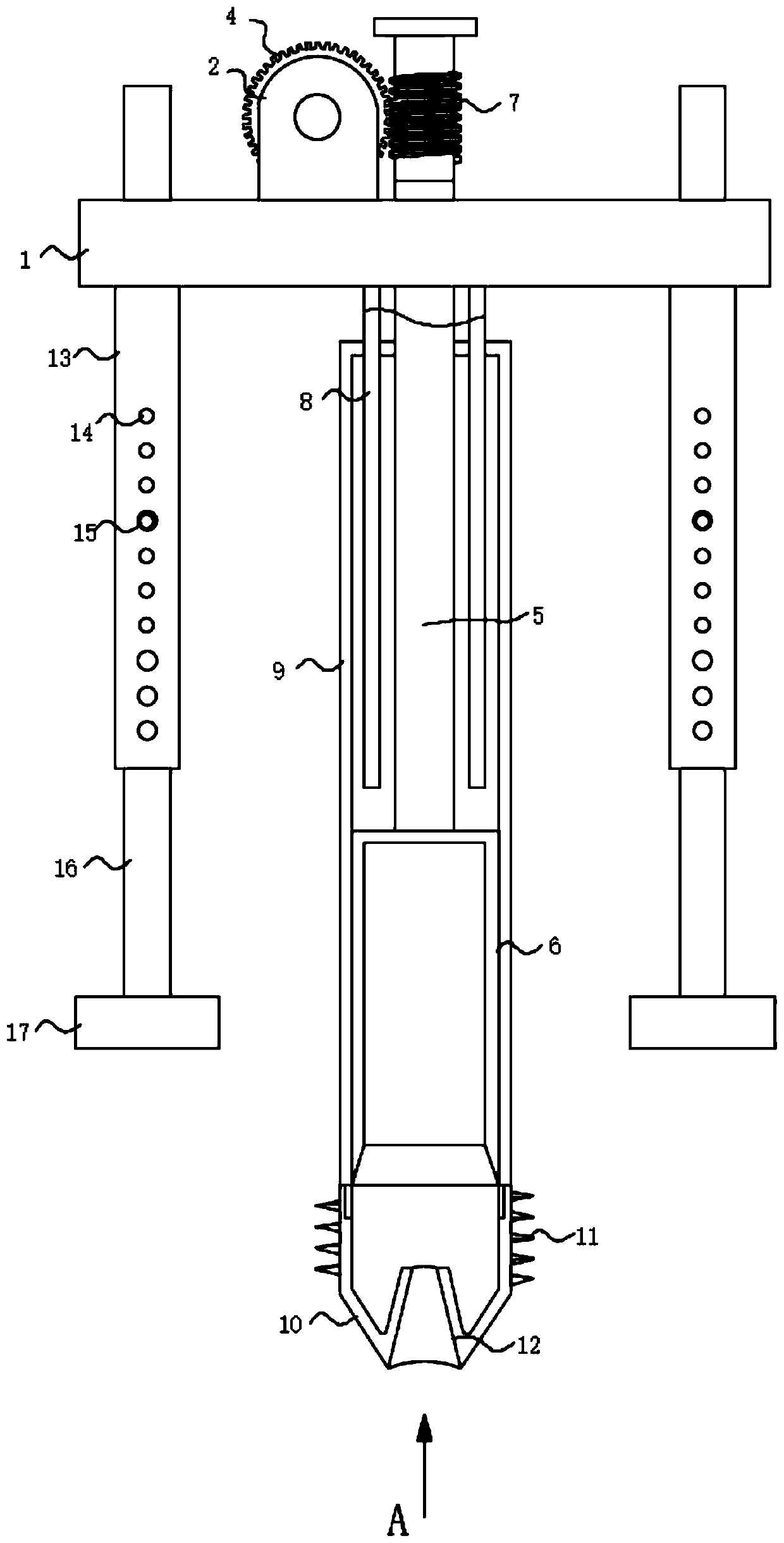

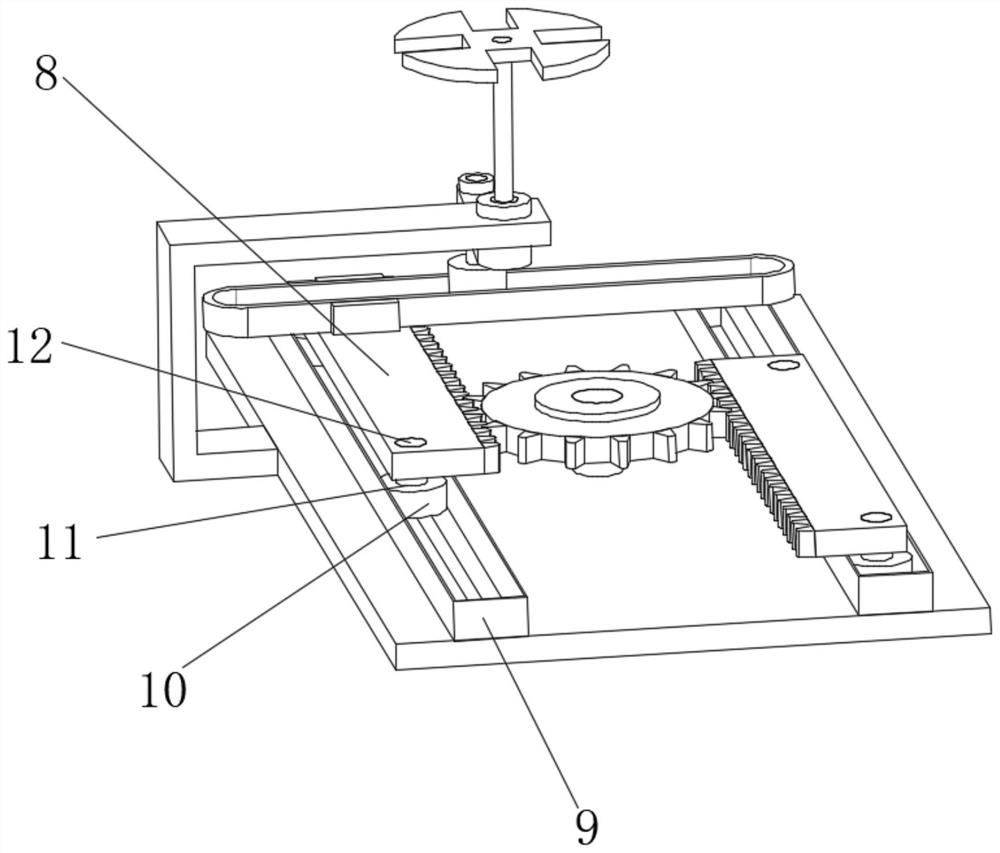

Deep soil sampler for soil texture detection

InactiveCN110887694AEasy to take outFacilitate repair workWithdrawing sample devicesSoil remediationAgricultural engineering

The invention discloses a deep soil sampler for soil texture detection. The deep soil sampler comprises a mounting base. A screw rod is connected in the middle part of the mounting base through a bearing; a sampling cylinder is connected on the screw rod in a threaded mode; a drilling cylinder is connected on the lower end part of the sampling cylinder in a threaded mode; spiral teeth are arrangedon the outer side of the drilling barrel; supporting plates are fixedly mounted on the front and the back of the the upper end surface of the mounting base; a hand rocker is connected on each supporting plate through a bearing; a turbine fixedly sleeves the middle of the hand rocker; first connecting rods are fixedly installed at the left lower end and the right lower end of the mounting base; second connecting rods are movably inserted in the inner cavities of the first connecting rods; second limiting blocks are fixedly inserted in the middle of the outer side faces of the second connectingrods; and the left end and the right end of the second limiting blocks are symmetrically sleeved with first limiting blocks. The deep soil sampler for soil texture detection is time-saving and labor-saving and improves the working efficiency of sampling personnel and brings great convenience to soil remediation work.

Owner:新昌县羽林街道巨晖机械厂

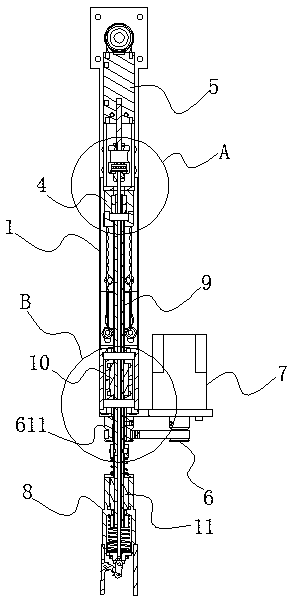

Flexible-rope tension clamping type insertion operating head of electronic component and insertion method of insertion operating head

InactiveCN105744756AFast and accurate insertionImprove insertion speedPrinted circuit assemblingElectrical componentsThrust bearingElectronic component

The invention discloses a flexible-rope tension clamping type insertion operating head of an electronic component and an insertion method of the insertion operating head. The insertion operating head comprises an insertion head support, a first synchronous belt device, a first control motor, an L-shaped sliding block, a clamping air cylinder, a second synchronous belt device, a second control motor, a flexible-rope tension clamping type clamping head, a spline shaft, a first spline shaft sleeve, a second spline shaft sleeve, a pull rod and a thrust bearing, wherein under the action of the clamping air cylinder, the flexible-rope tension clamping type clamping head can be controlled to a clamping or loosen state by the pull rod; by the first control motor, the first synchronous belt can drive the L-shaped sliding block, the clamping air cylinder, the pull rod, the spline shaft, the second spline shaft sleeve and the flexible-rope tension clamping type clamping head to vertically move upwards and downwards; a second driven pulley of the second synchronous belt device is fixedly connected with the outer peripheral surface of the first spline shaft sleeve; and by the second control motor, the second driven pulley can be driven to rotate, so that the first spline shaft sleeve, the spline shaft, the second spline shaft sleeve and the flexible-rope tension clamping type clamping head can be driven to rotate around the axial line of the spline shaft in a horizontal direction.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

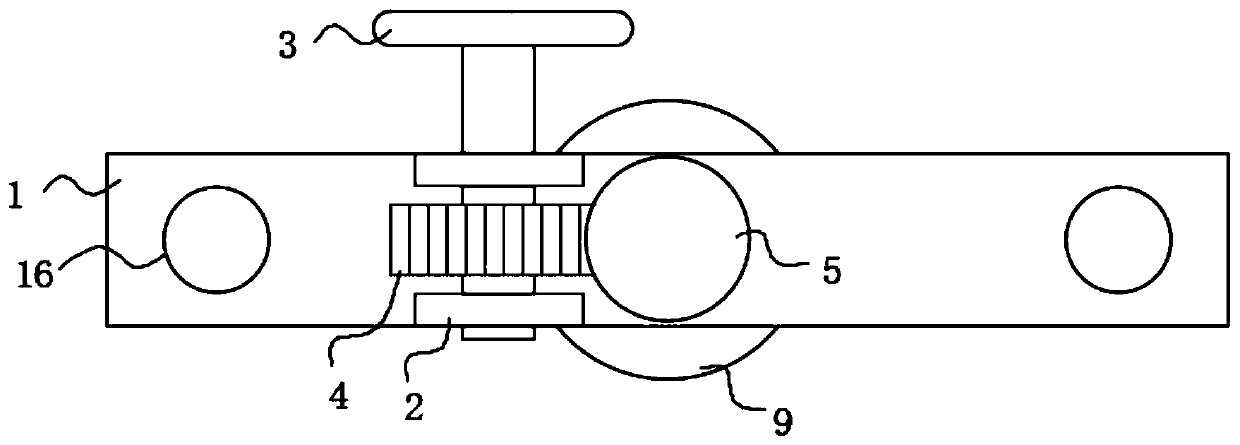

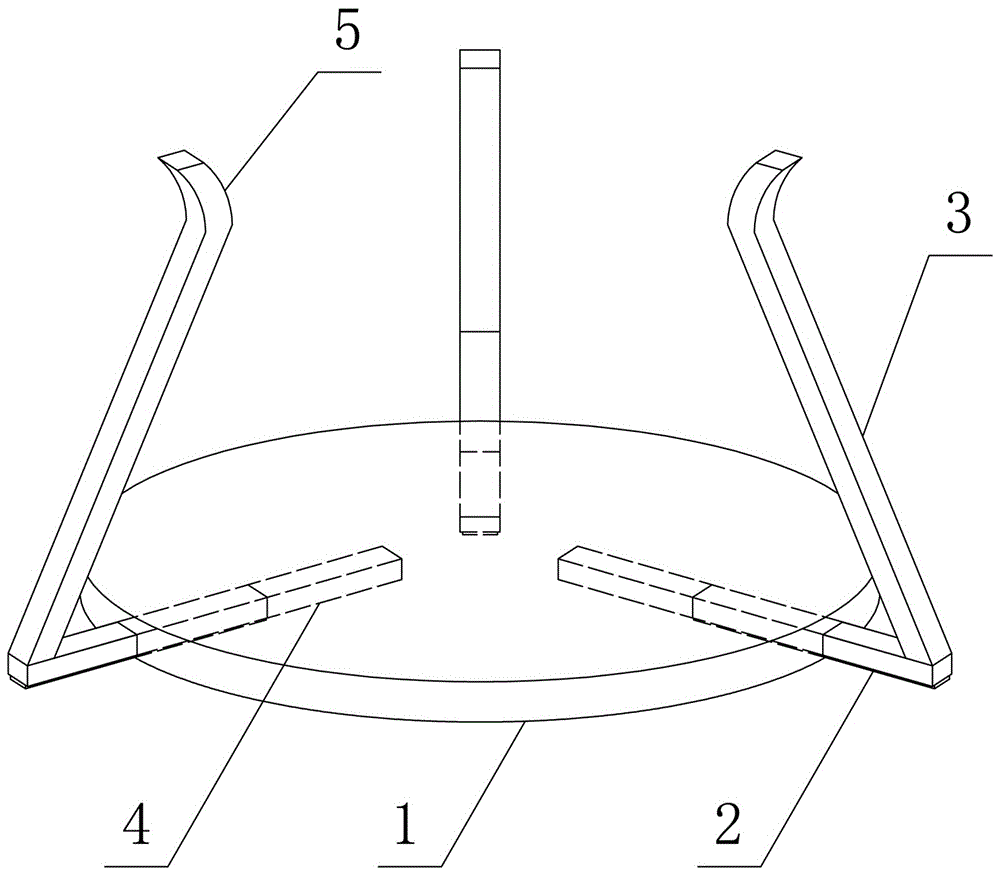

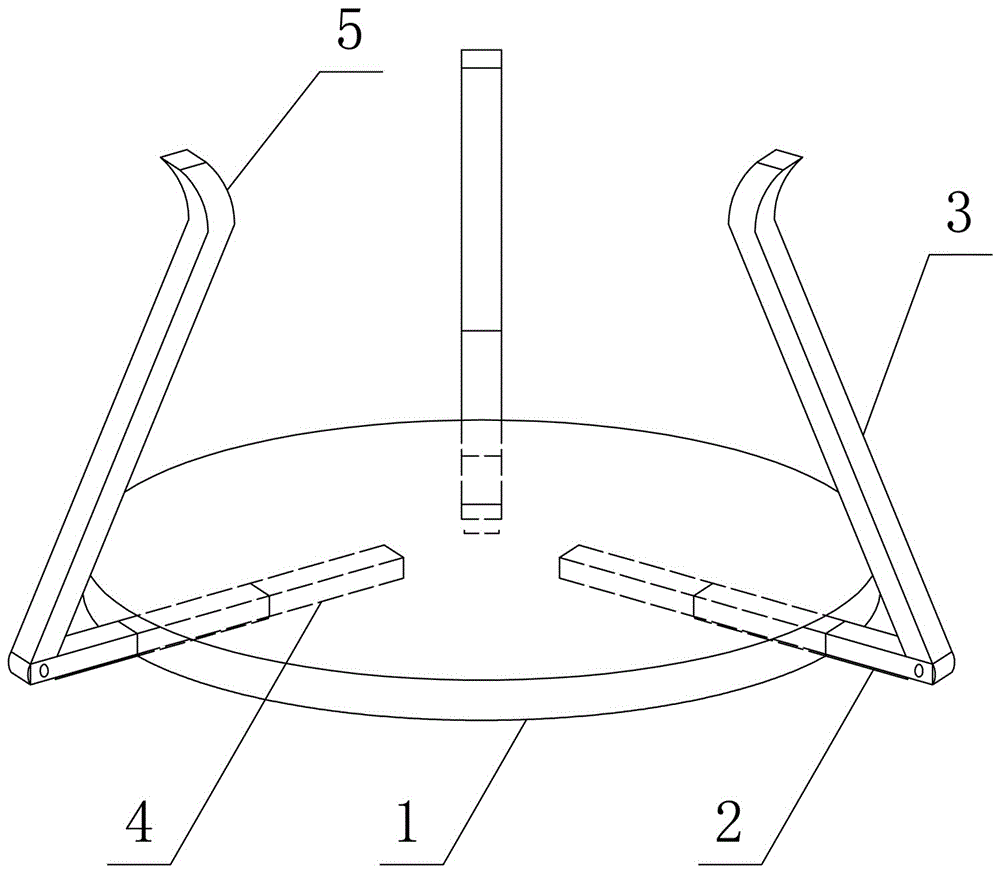

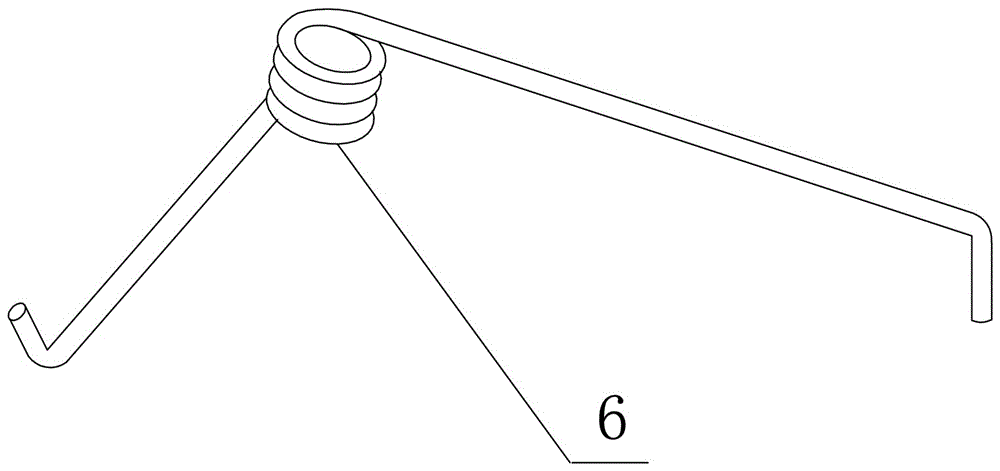

Novel tipping-resistant foundation

InactiveCN106419446AAchieve fixationSimple structureKitchen equipmentDomestic articlesStructural engineeringEngineering

The invention discloses a novel tipping-resistant foundation. The tipping-resistant foundation comprises a base plate (1), a horizontal rod (2), and a tilting rod (3), wherein an holding groove (4) is formed in the lower end face of the base plate (1), one end of the horizontal rod (2) is plugged into the holding groove (4), the other end of the horizontal rod (2) stretches out of the holding groove (4) and is connected with the lower end of the tilting rod (3), and an outwards turning part (5) is arranged at the upper end of the tilting rod (3). By using the horizontal rod plugged into the base plate, the contact area between the novel tipping-resistant foundation and a table top can be effectively increased, thus overall structural stability of a container in the novel tipping-resistant foundation can be improved, and the technical problem of unsteady placing of the container can be fundamentally solved.

Owner:宋可宁

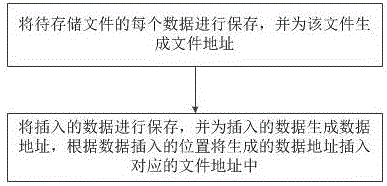

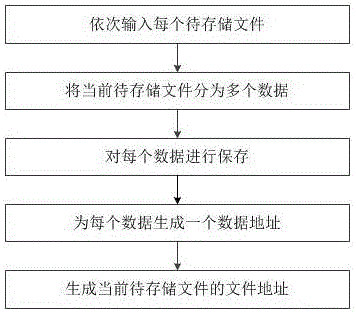

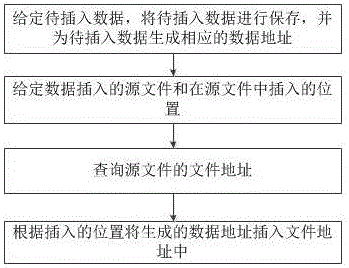

Data insertion method and system based on storage of FICS objects

InactiveCN106021536AImprove insertion speedSave read and write bandwidthFile access structuresSpecial data processing applicationsStored procedureDatabase

The invention discloses a data insertion method and system based on storage of FICS objects. The method comprises following steps: S1, file storage: saving each data of files to be stored and generating file addresses of files to be stored; S2, file insertion: saving inserted data, generating data addresses of inserted data and inserting generated data addresses to corresponding file addresses according to data insertion positions. The data insertion method and system based on storage of FICS objects have following beneficial effects: during storage, each data of files can be saved and file addresses can be generated; during file insertion, inserted data is saved and data addresses are generated to inserted data; according to data insertion positions, generated data addresses are inserted into corresponding file addresses; there is no need to cover all content of files for once; data insertion speed is increased and read-write bandwidth occupied by data insertion is saved.

Owner:CHENGDU SOBEY DIGITAL TECH CO LTD

Bamboo stick stringing device

ActiveCN113768178ATo achieve the purpose of transmissionAvoid splittingFood shapingStructural engineeringString (device)

The invention relates to a skewer food processing related device, in particular to a bamboo stick stringing device The bamboo stick stringing device comprises a conveying base, a stick rotating mechanism, a bamboo stick correcting mechanism and a cutting mechanism, wherein the stick rotating mechanism is fixedly mounted on the conveying base, the bamboo stick correcting mechanism is fixedly mounted on the stick rotating mechanism, the bamboo stick correcting mechanism is slidably mounted on the stick rotating mechanism, and the cutting mechanism is in threaded connection with the stick rotating mechanism. The device can prevent the tips of bamboo sticks from being split, so that the utilization rate of the bamboo sticks is greatly increased, and the device can adapt to the bamboo sticks with different lengths and can be used for processing kebabs with different sizes.

Owner:义乌市玮希科技有限公司

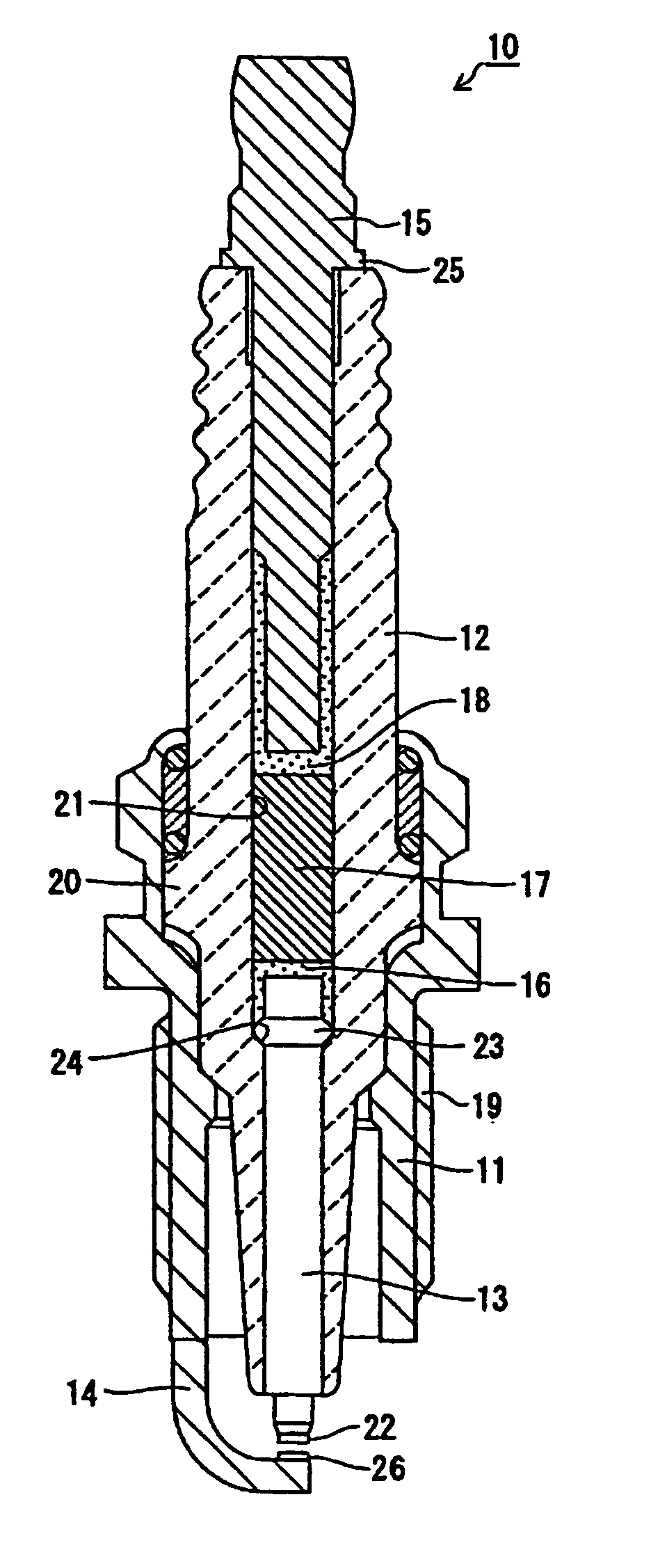

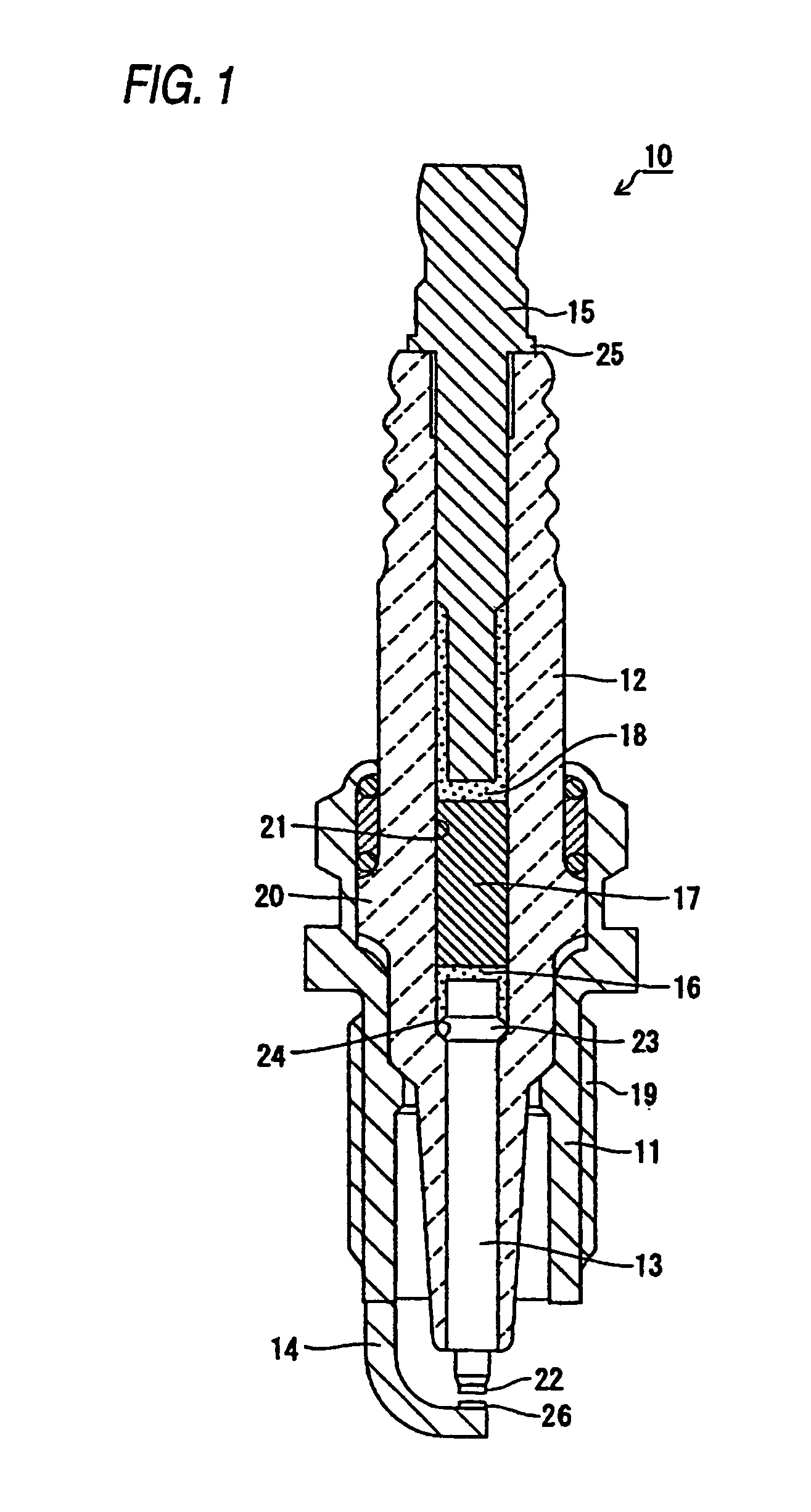

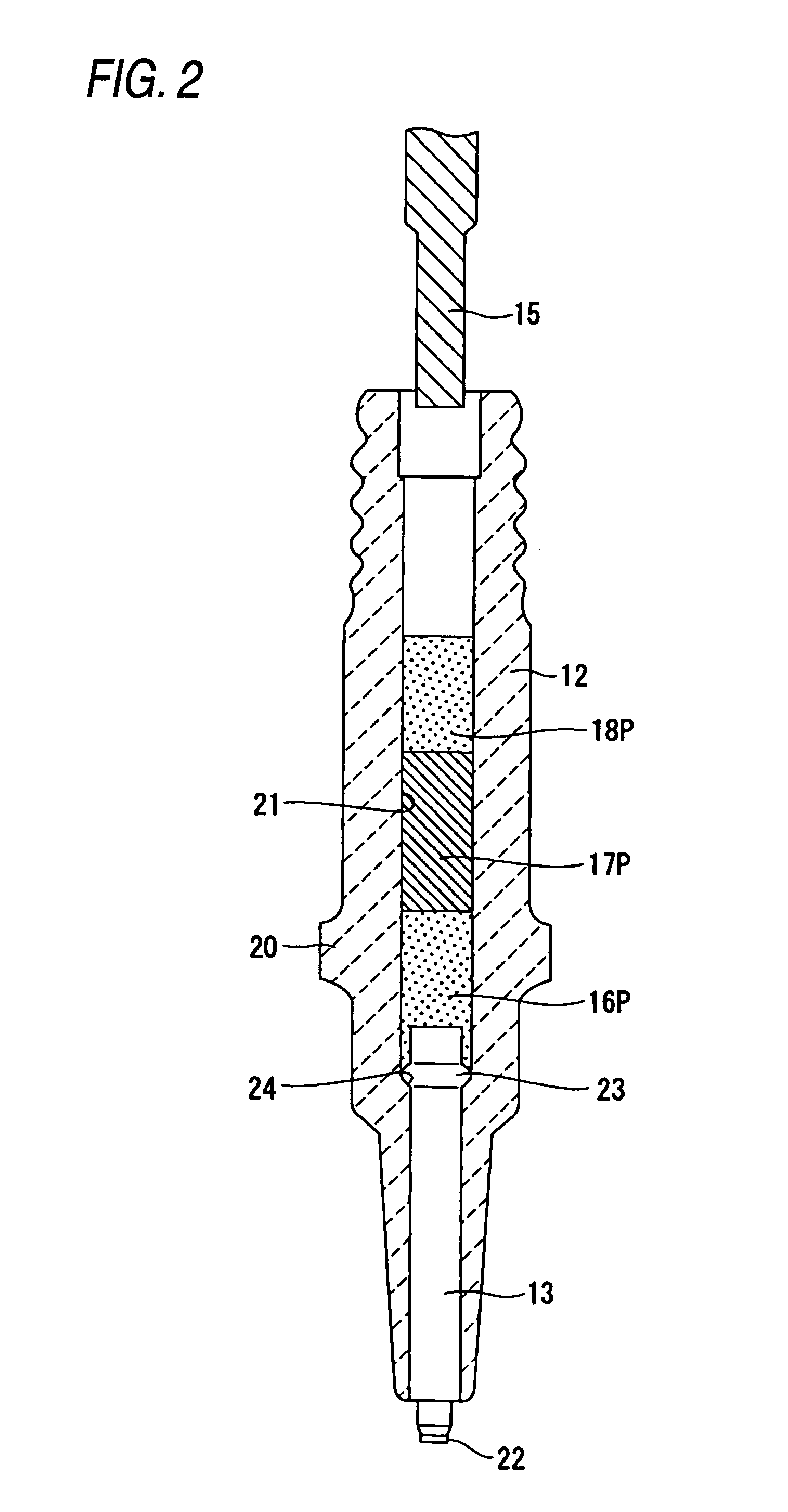

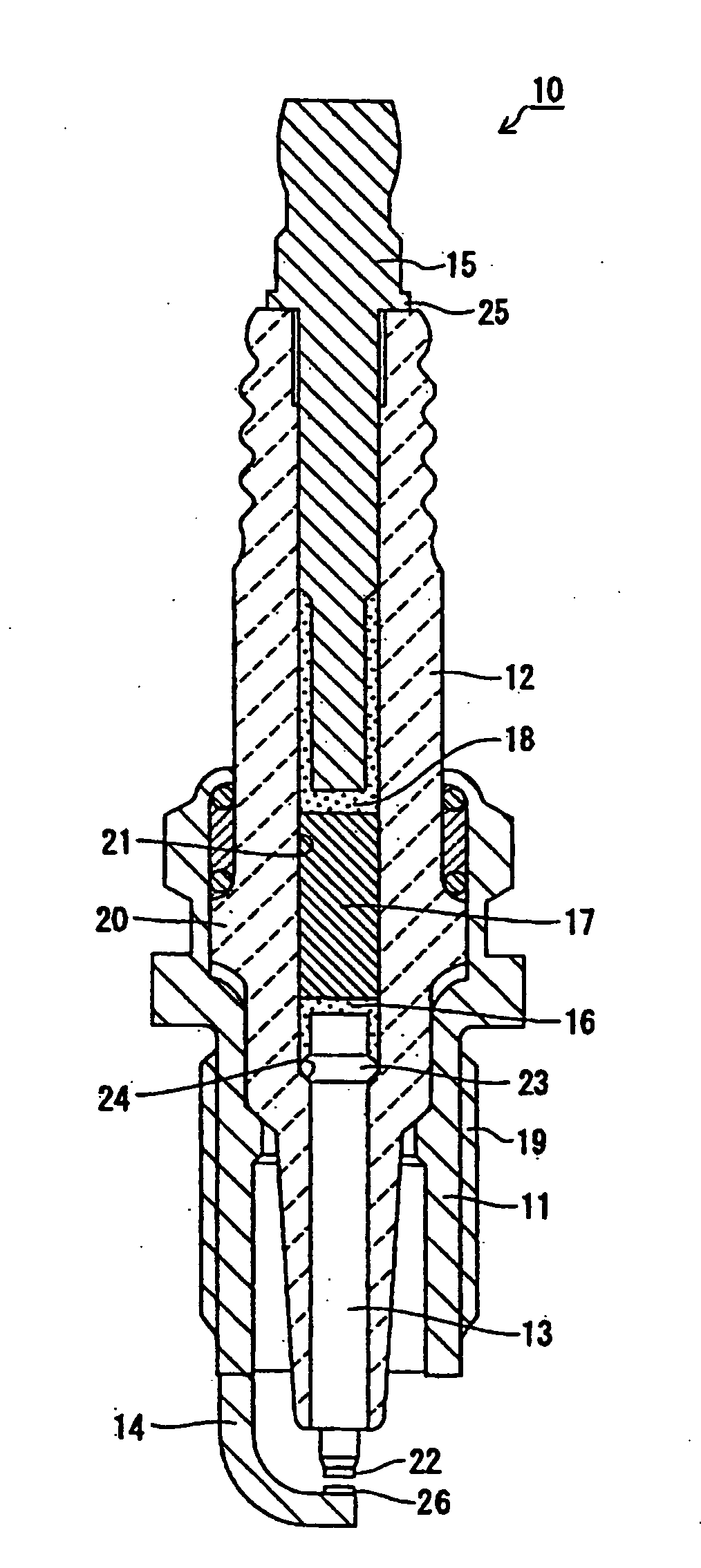

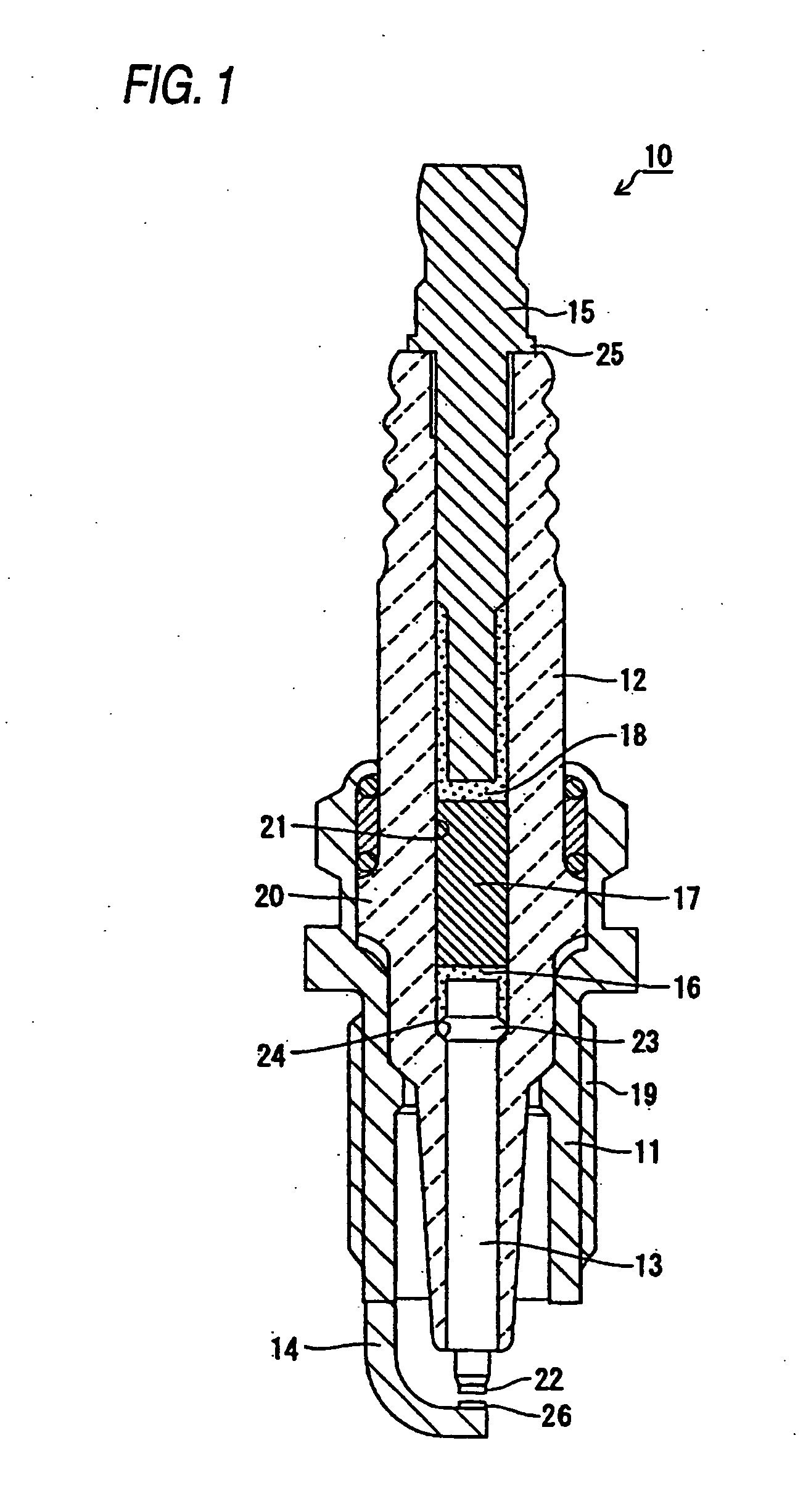

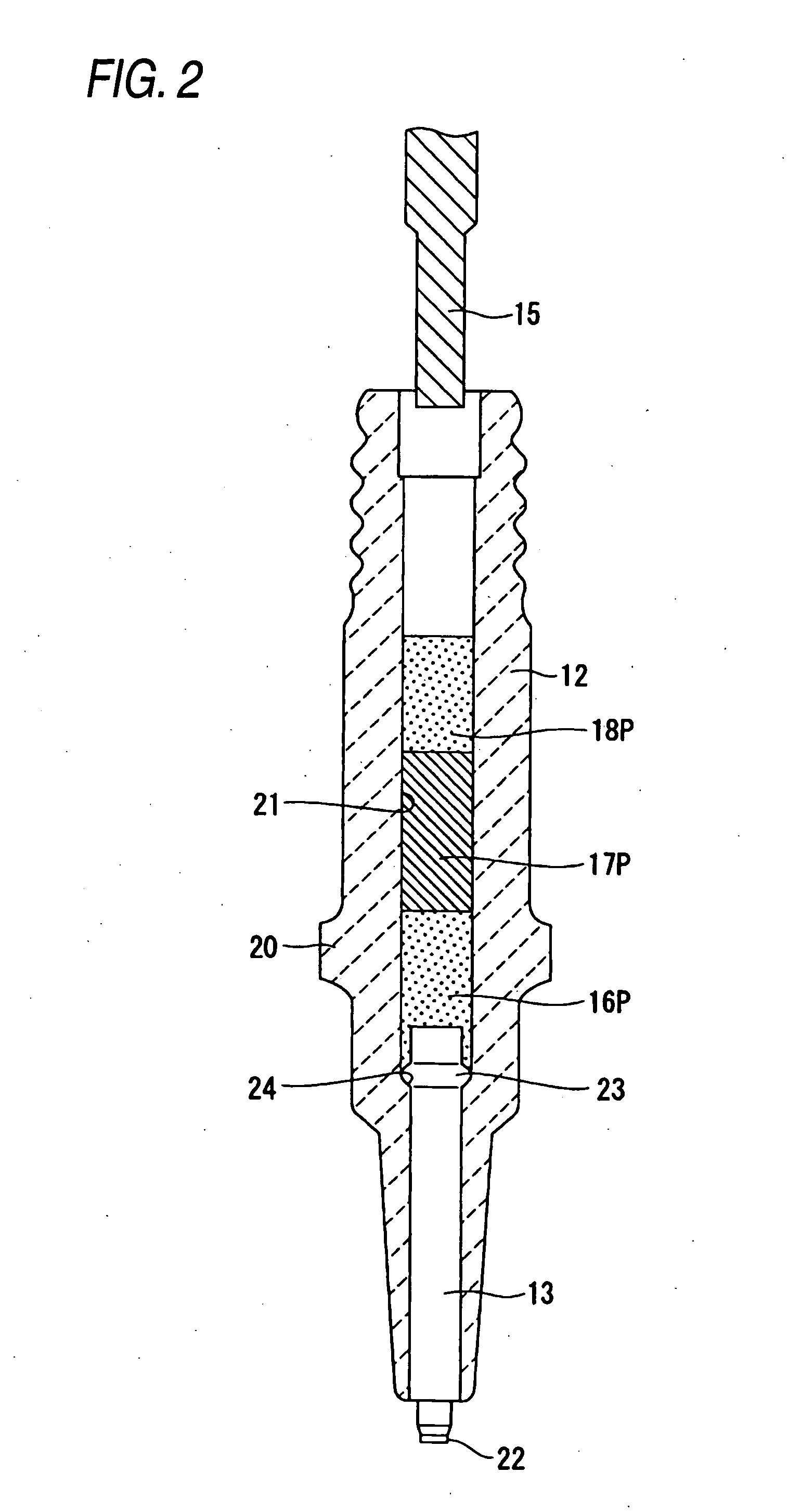

Method of manufacturing spark plug

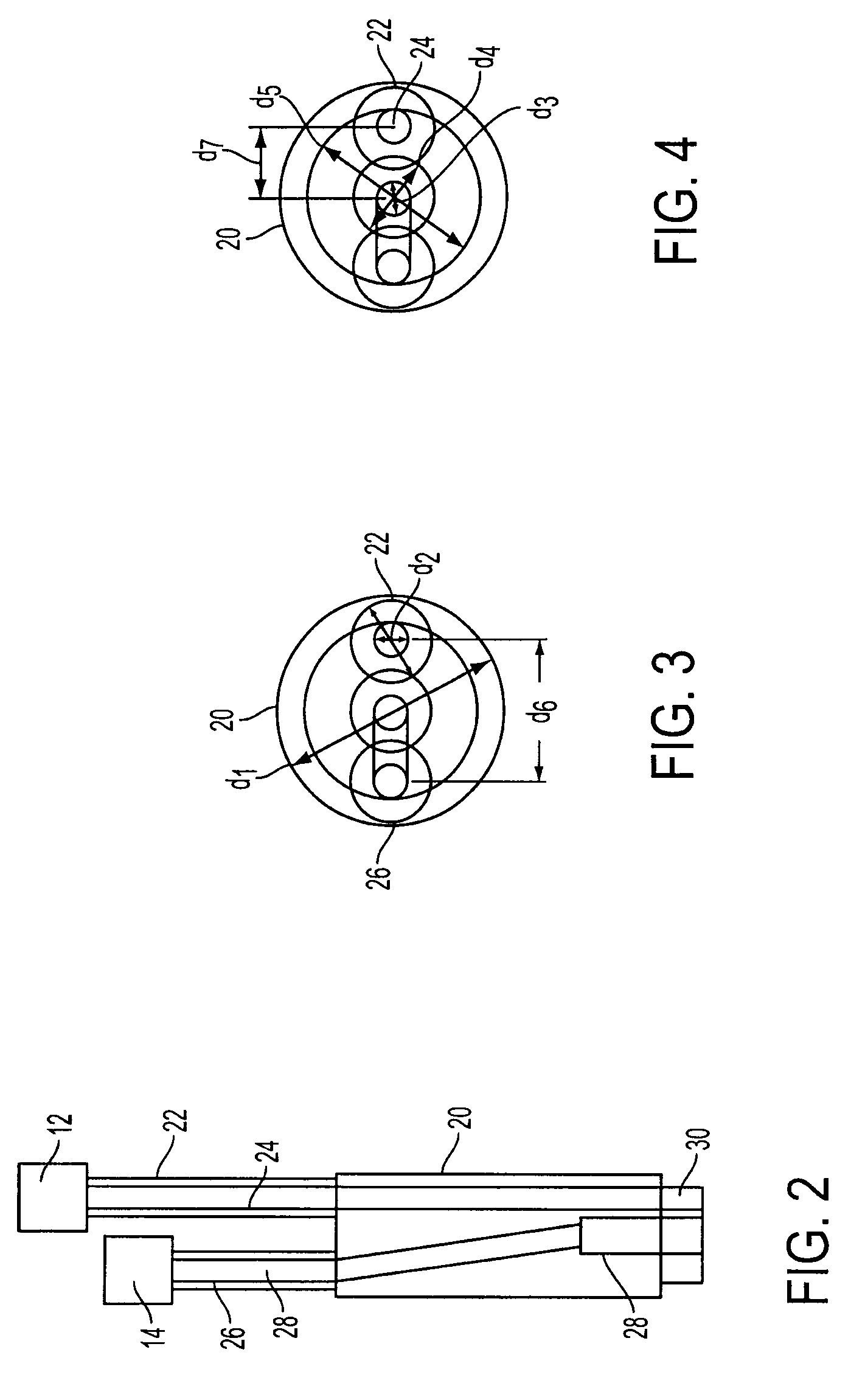

ActiveUS8092269B2Increase loadLow degreeSpark gapsSparking plugs manufactureUltimate tensile strengthResistor

Owner:NGK SPARK PLUG CO LTD

Method of manufacturing spark plug

ActiveUS20100233929A1Increase loadLow degreeSpark gapsSparking plugs manufactureUltimate tensile strengthResistor

A decrease in yield and degradation of productivity can be avoided when a spark plug having an insulator with low mechanical strength is manufactured. In a second process, a terminal electrode 15 is inserted to a predetermined position in a state where an insulator 12 is heated to a temperature equal to or greater than the softening temperatures of first to third powder materials 16P, 17P, and 18P such that the first powder material 16P becomes a first conductive sealing material layer 16, the second powder material 17P becomes a resistor 17, and the third powder material 18P becomes a second conductive sealing material layer 18. In addition, a speed at which the terminal electrode 15 is inserted is reduced between the start and the end of the second process.

Owner:NGK SPARK PLUG CO LTD

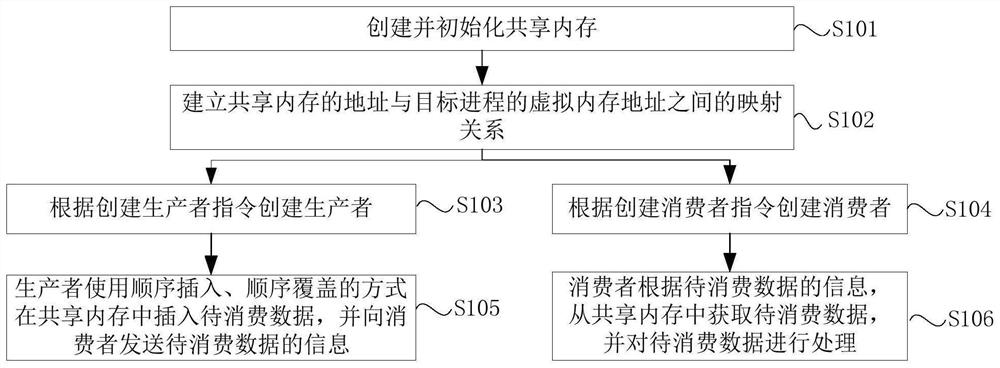

Cache sharing method and device and electronic equipment

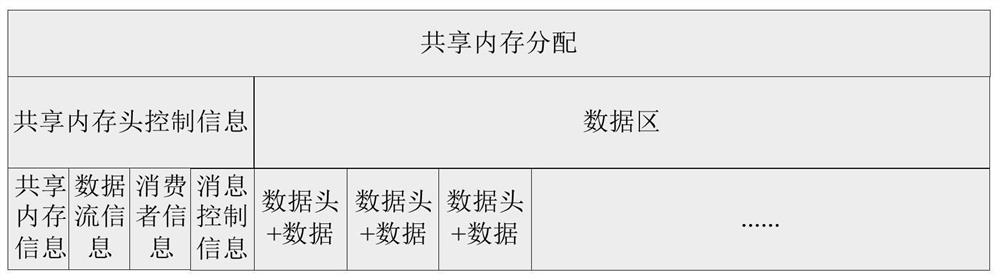

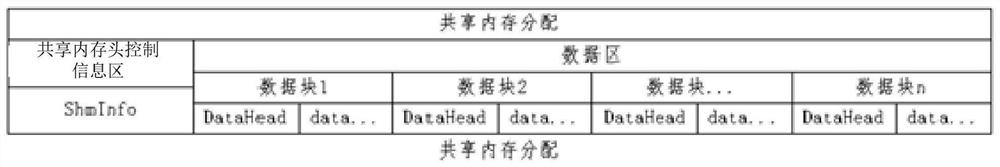

PendingCN113176942AFlexible useIncrease profitInput/output to record carriersResource allocationVirtual memoryTerm memory

Embodiments of the invention provide a cache sharing method and device, and electronic equipment. The method comprises the steps that a shared memory is created and initialized; a mapping relationship between the address of the shared memory and the virtual memory address of a target process is established; a producer is created according to a producer creation instruction, and a consumer is created according to the consumer creation instruction; the producer inserts to-be-consumed data into the shared memory in a sequential insertion and sequential coverage mode and sends the information of to-be-consumed data to the consumer, wherein sequential insertion and sequential coverage indicate that the data area of the shared memory is repeatedly traversed from beginning to end, so that the to-be-consumed data is inserted into the shared memory in a sequential insertion and sequential coverage manner; and the consumer obtains the to-be-consumed data from the shared memory according to the information of the to-be-consumed data, and processes the to-be-consumed data. According to the invention, the memory utilization rate can be improved and the data processing delay is reduced.

Owner:北京蓝色星云科技发展有限公司

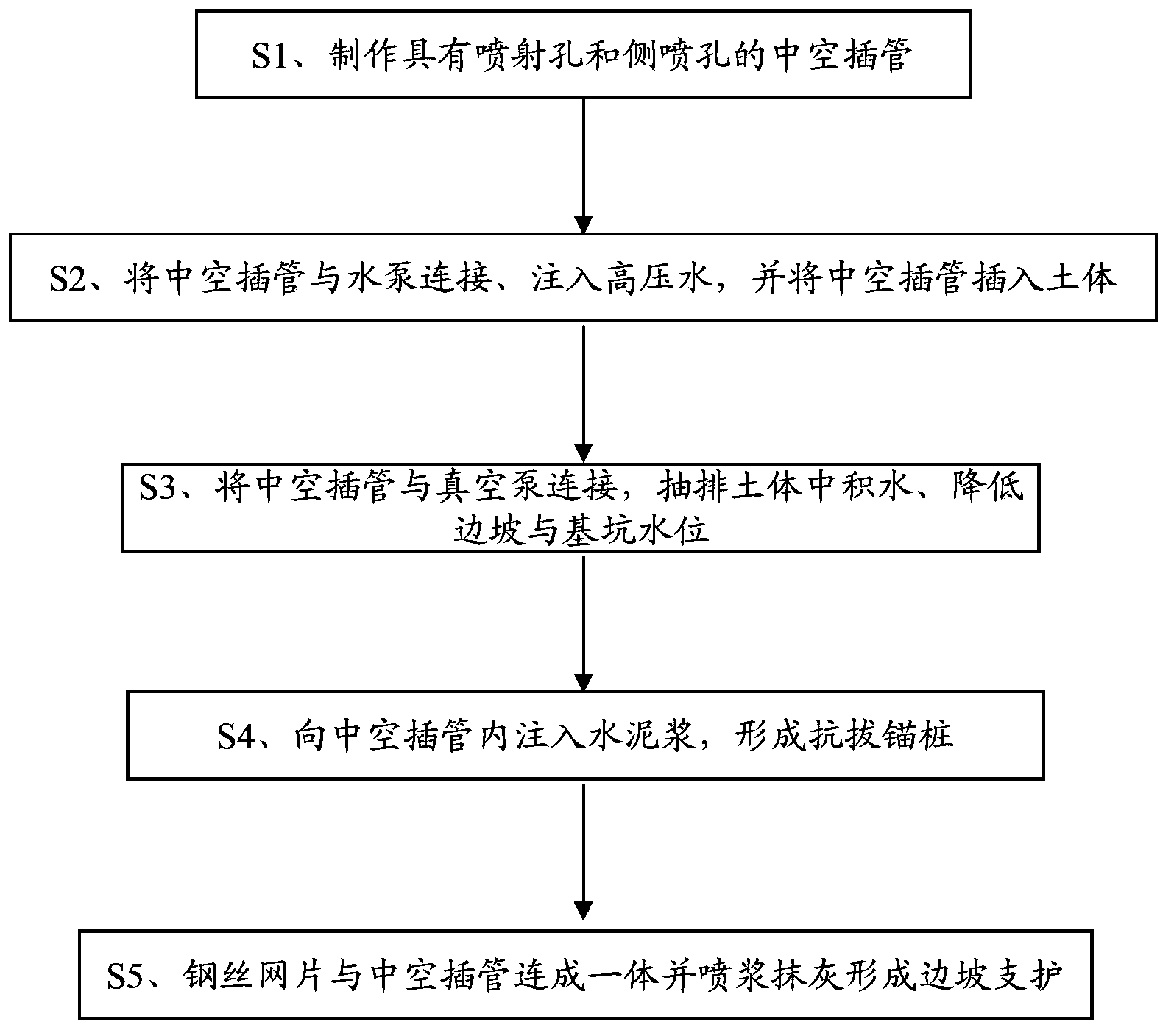

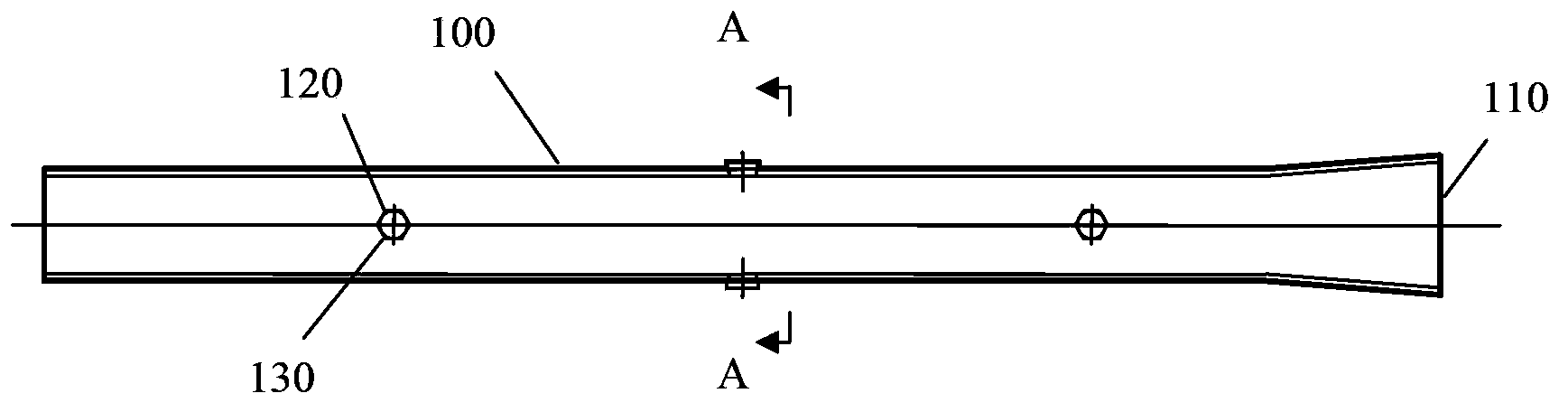

Foundation pit slope soil-nailing dewatering support construction method

ActiveCN103452118AInsert smoothlyOvercome the defect that it is difficult to form holes in constructionExcavationsSoil nailingEngineering

The invention discloses a foundation pit slope soil-nailing dewatering support construction method. The construction method includes firstly, inserting a hollow insertion pipe into a soil body in a mode that the hollow insertion pipe with the end and the side wall both provided with jet holes is injected with water to jet the soil body, secondly, connecting a water pump with the hollow insertion pipe to pump water in the soil body and a foundation pit, thirdly, injecting cement paste into the hollow insertion pipe to form an anti-pulling anchor pile, and finally, connecting the anti-pulling anchor pile and a steel wire mesh into a whole prior to whitewashing and plastering to form a slope support. The construction method has the advantage of suitability for construction in rainy soft soil areas, and is shorter in construction period, low in energy and consumption, green, environmentally friendly and higher in construction cost as compared with the prior art.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

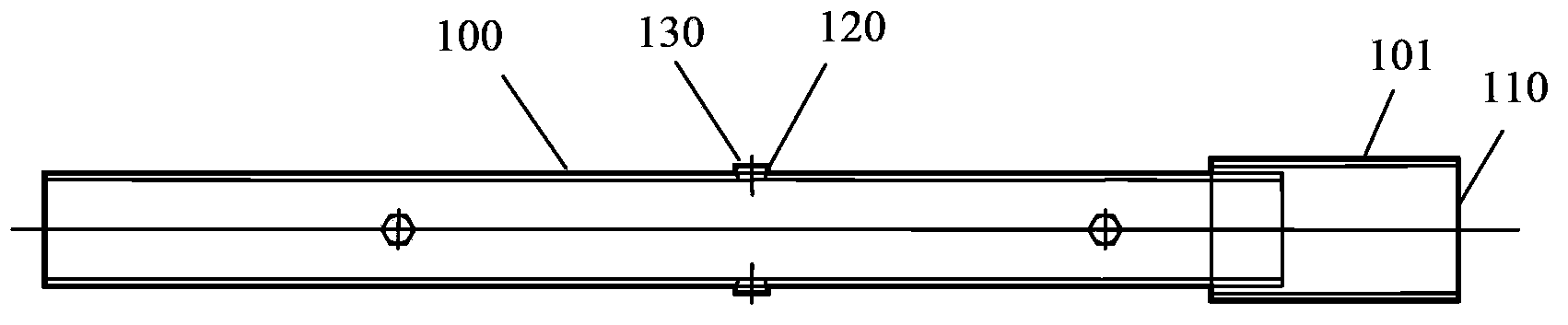

Apparatus and method for coating of elongate flimsy members

ActiveUS20070221123A1Improve reliabilityIncrease speedGlovesPharmaceutical containersBiomedical engineeringCoating

A coating apparatus and method for flimsy elongate members has at least one elongate funnel tube with an inlet, an outlet, and an intermediate portion, the inlet in a basin, a fluid circulating system suitable connecting the outlet to provide flow into the inlet. Each inlet receives an elongate flimsy component and utilizes the circulating fluid to pull the flimsy elongate member into the funnel tube whereby the coating of the flimsy elongate member is accomplished. The invention also includes the method for coating such a flimsy elongate member utilizing the coating apparatus.

Owner:HARLAND MEDICAL SYST

A medium-sized electronic component sticking and inserting operation head and its sticking and inserting method

InactiveCN105744755BFast and accurate insertionImprove insertion speedPrinted circuit assemblingElectrical componentsThrust bearingEngineering

The invention discloses an insertion operating head of a middle-sized electronic component and an insertion method of the insertion operating head. The insertion operating head comprises an insertion head support, a first synchronous belt device, a first control motor, an L-shaped sliding block, a clamping air cylinder, a second synchronous belt device, a second control motor, a single-side movable clamping claw type clamping head, a spline shaft, a first spline shaft sleeve, a second spline shaft sleeve, a pull rod, a pull rod connection sleeve and a thrust bearing, wherein under the action of the clamping air cylinder, the single-side movable claw type clamping head can be controlled to be a clamping or loosen state by the pull rod; under the rotation of the first control motor, the first synchronous belt can drive the L-shaped sliding block, the clamping air cylinder, the spline shaft and the single-side movable claw type clamping head to vertically move upwards and downwards; a second driven pulley of the second synchronous belt device is fixedly connected with the outer peripheral surface of the first spline shaft sleeve; and through the rotation of the second control motor, the second driven pulley, the first spline shaft sleeve, the spline shaft, the second spline shaft sleeve, the single-side movable claw type clamping head, the pull rod and an upper ring of the thrust bearing can be driven to rotate around the axial line of the spline shaft in a horizontal direction.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

A kind of vanadium-based catalyst and preparation method thereof and preparation method of ethylene-propylene copolymer

The invention provides a vanadium catalyst with a general formula of VO(RSO3)mCln.xR'OH, wherein m+n=3, and m is 1, 2 or 3, n is 0, 1 or 2; x is within 1-3.5; RSO3<-> has a structure shown in formula I; R is a C1-C20 linear or branched alkyl, aryl, aralkyl or halogen-substituted alkyl, halogen-substituted aryl, and halogen-substituted aralkyl; R'OH is straight chain aliphatic alcohol or branched chain aliphatic alcohol with carbon atom number of 5-10. The vanadium catalyst provided by the invention has the advantages of high activity and low cost. The invention also provides a preparation method of the catalyst and a preparation method of binary or ternary ethylene-propylene copolymer by using the catalyst. The following formula is the formula I.

Owner:中科应化(长春)科技有限公司

Electrified mounting and dismounting device for magnetic bird repeller

PendingCN114843969AImprove stabilityPracticalOverhead installationAnimal repellantsGear wheelElectric power equipment

The invention relates to the technical field of power equipment, and discloses a magnetic type bird repeller live-line mounting and dismounting device which comprises a mounting substrate, and two fixing sleeve shells are fixedly mounted at the top of the mounting substrate. According to the electrified mounting and dismounting device for the magnetic bird repeller, a connecting handle is used for controlling an extension connecting convex block fixedly clamped to the surface of an internal fixing shaft to rotate, and a push rod connected with the extension connecting convex block reciprocates in an annular sleeve shell fixedly mounted on the side face of a rack top fixing block in the rotating process; two rotating round blocks movably connected with the bottom of a rotating column fixedly clamped with the racks move in the fixed sleeve shell, and in the moving process, the two racks are meshed with an auxiliary gear, the auxiliary gear serves as a center linkage piece to rotate on the surface of the fixed column, and therefore the two racks are in a synchronous moving state; the stability of two-point installation is high, the installation distance can be synchronously adjusted, and the practicability is higher.

Owner:STATE GRID SHANDONG ELECTRIC POWER

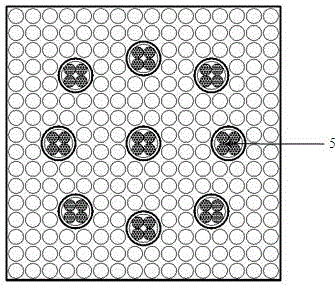

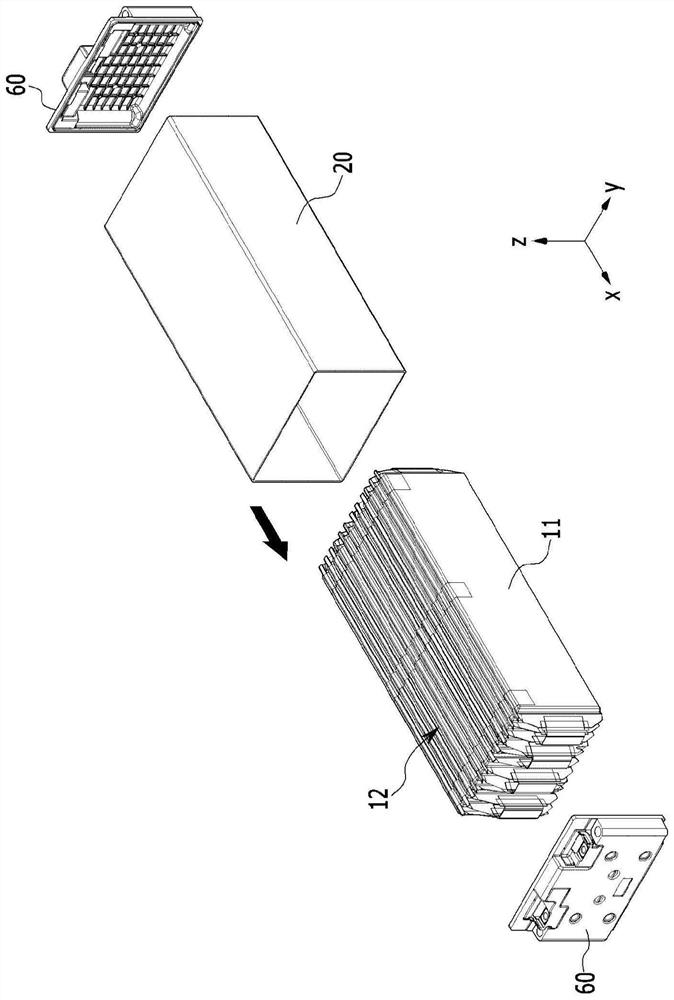

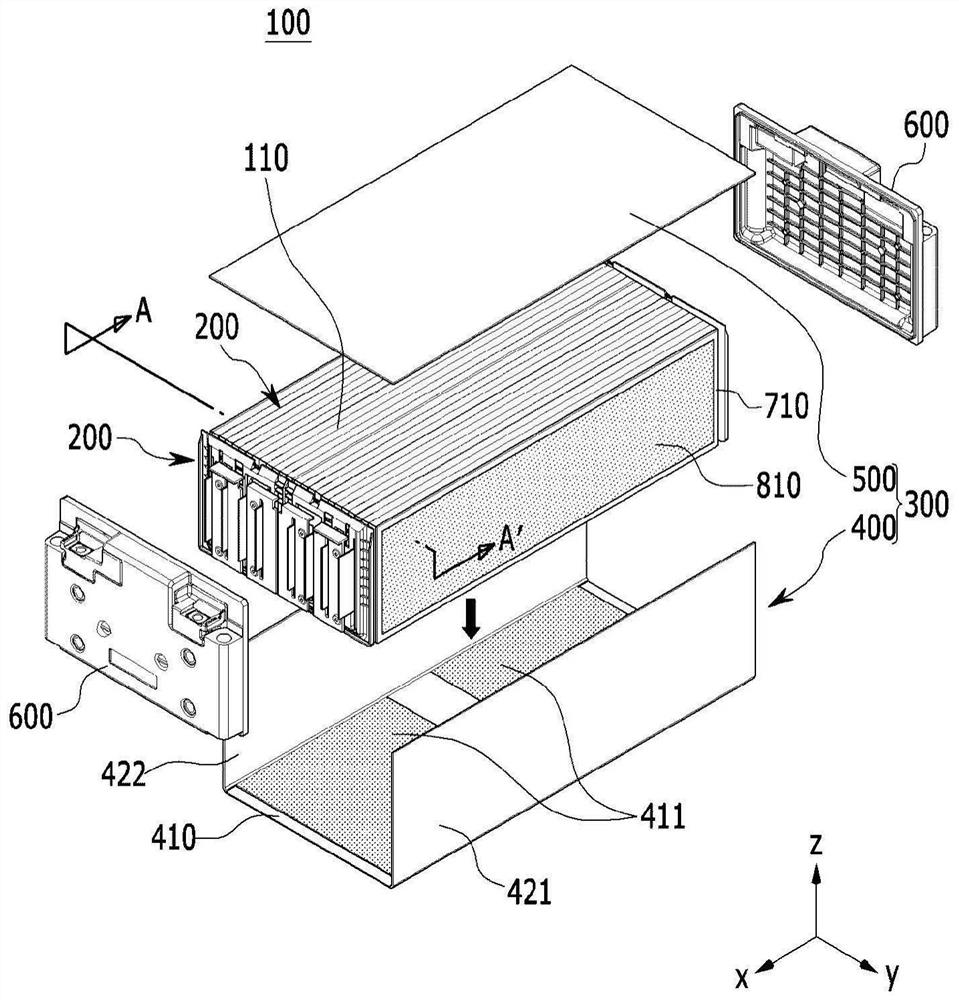

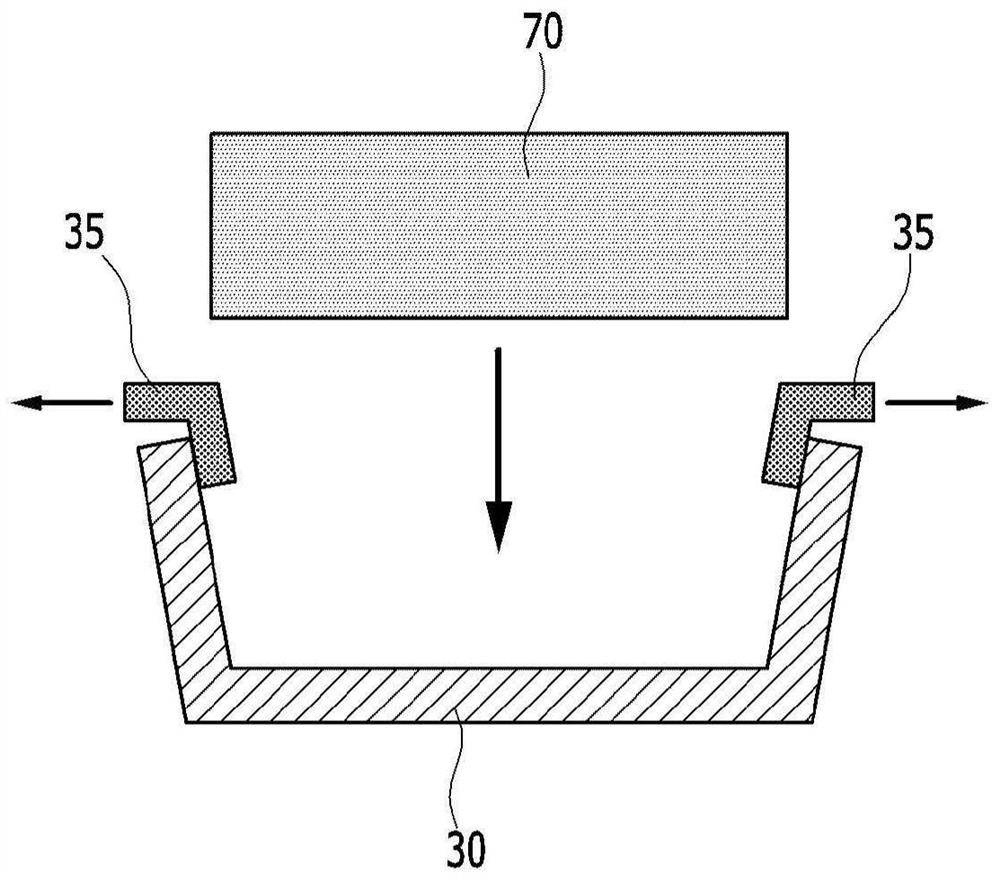

Apparatus and method for manufacturing battery module

PendingCN114730950AImprove insertion speedLow costFinal product manufactureSecondary cellsStructural engineeringMechanical engineering

A battery module manufacturing apparatus according to an embodiment of the present invention includes a guide plate surrounding a battery cell stack in which a plurality of battery cells are stacked from left and right sides thereof, in which the guide plate includes: a main body portion in contact with the battery cell stack; and an insertion portion connected to one end portion of the main body portion and bent toward an inner side of the battery cell stack and then protruding, and through which the battery cell stack is inserted into a frame member of an upper portion having an opening.

Owner:LG ENERGY SOLUTION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com