Vanadium catalyst and preparation method of vanadium catalyst as well as preparation method of ethylene-propylene copolymer

A catalyst and vanadium-based technology, applied in the field of polymer synthesis, can solve the problems of inability to improve catalyst activity, poor stability, and high toxicity, and achieve the effects of low risk, high catalytic activity, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a preparation method of vanadium catalyst, comprising:

[0038] a) Provide the general formula as VOCl 3 Vanadium complexes of xR'OH; wherein x is 1-3.5; R'OH is a straight chain or branched fatty alcohol with 5-10 carbon atoms;

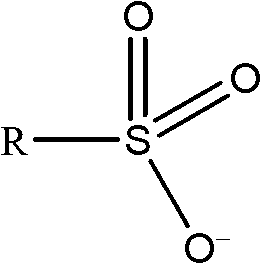

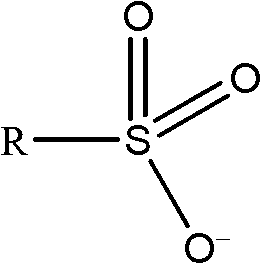

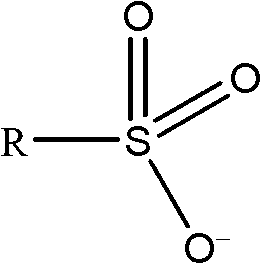

[0039] b) Mix the vanadium complex provided in step a) with the modifier in the first organic solvent, and undergo a substitution reaction to obtain the general formula VO(RSO 3 ) a vanadium-based catalyst of mCln x R'OH; m+n=3, wherein m is 1, 2 or 3, and n is 0, 1 or 2;

[0040] Wherein the modifying agent is sulfonic acid and its derivatives; R is C1~C20 linear or branched alkyl, aryl, aralkyl or halogenated alkyl, halogenated aryl, halogenated aralkyl.

[0041] To prepare the vanadium catalyst of the present invention, at first the general formula will be VOCl 3 The vanadium complex of xR'OH is prepared according to the present invention, preferably according to the preparation method provided by the ...

Embodiment 1

[0061] The raw material is: a complex with vanadium as the central atom and fatty alcohol as the ligand, and its composition is VOCl3 xROH, where R is an alkyl group, and x is 1, 2 or 3. The specific preparation method of the raw material is as described in the patent CN 101108885A (publication number);

[0062] The sulfonic acid reagent is: trifluoromethanesulfonic acid;

[0063] The amount of sulfonic acid added: calculated according to the amount of vanadium added, the molar ratio of sulfonic acid and vanadium added is Q 钒 / Q 磺酸 =1~3;

[0064] The diluent is: saturated alkanes with 6-8 carbon atoms;

[0065] Reactant mixing time: 2-30 minutes;

[0066] Temperature conditions: -20°C—room temperature;

[0067] The reactor is: ampoule;

[0068] Preparation steps: Add VOCl3 xROH saturated alkane solution into the reactor according to the calculated amount, add sulfonic acid solution, mix thoroughly for 10-20 minutes by shaking or stirring, take samples and analyze an...

Embodiment 2

[0070] Preparation of other organic sulfonate vanadium compounds and preparation of complexes:

[0071] The preparation steps are as follows: under the conditions of heating at 60°C and stirring at 300 rpm, the organic sulfonic acid solution is added to the vanadium compound hexane solution with fatty alcohol as a ligand, wherein the organic sulfonic acid and fatty alcohol are ligands The molar ratio of the vanadium compound is 1:1 (or 2:1, 3:1). After 2 hours of reaction, the reaction solution is poured into a separatory funnel, left to separate the phases, the lower aqueous phase is released, and the upper organic phase is retained, that is A vanadium-based catalyst modified with an organic sulfonic acid is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com