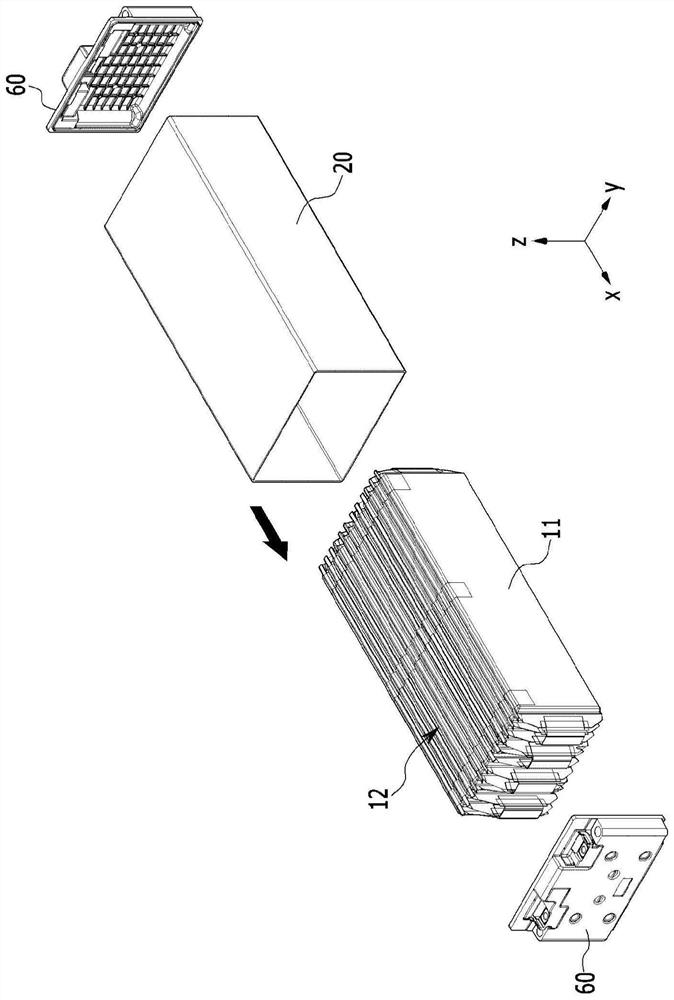

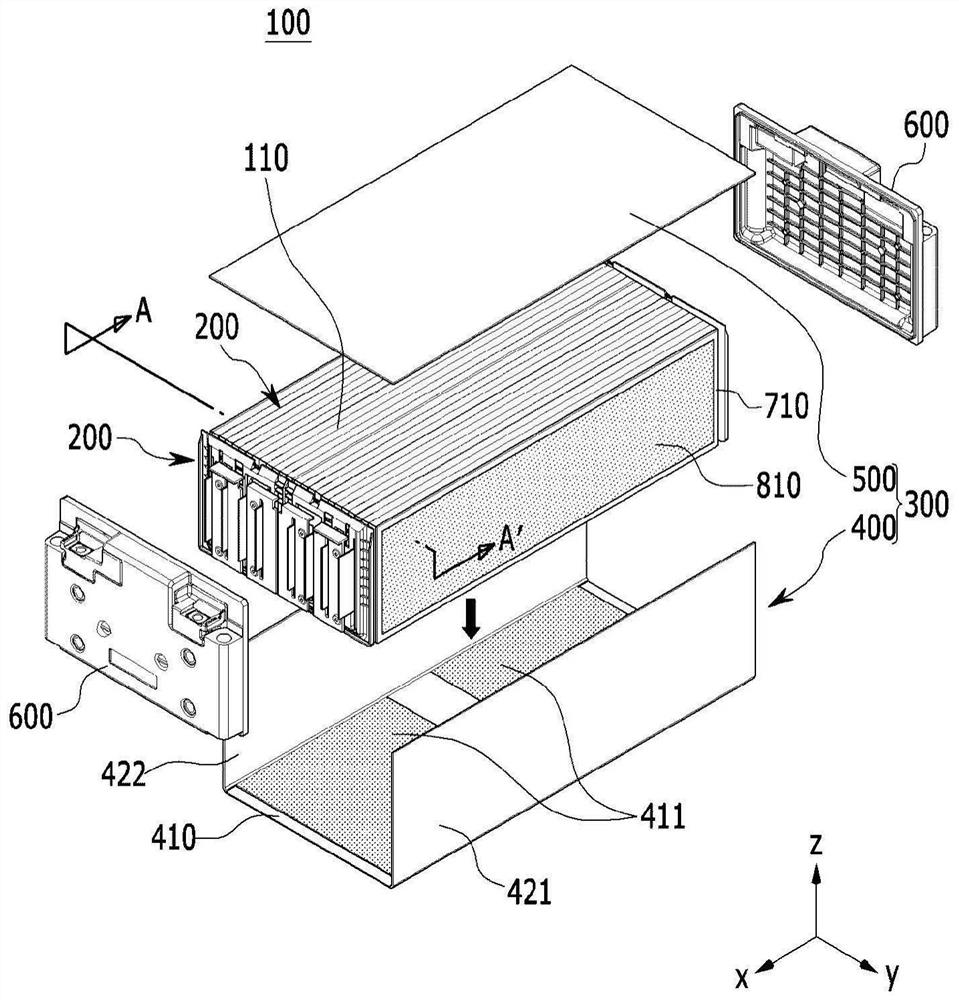

Apparatus and method for manufacturing battery module

A battery module and equipment technology, applied in the field of battery module equipment, can solve problems such as wasted space, increased cost, and damage to the guide film, and achieve the effects of reducing costs and increasing insertion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

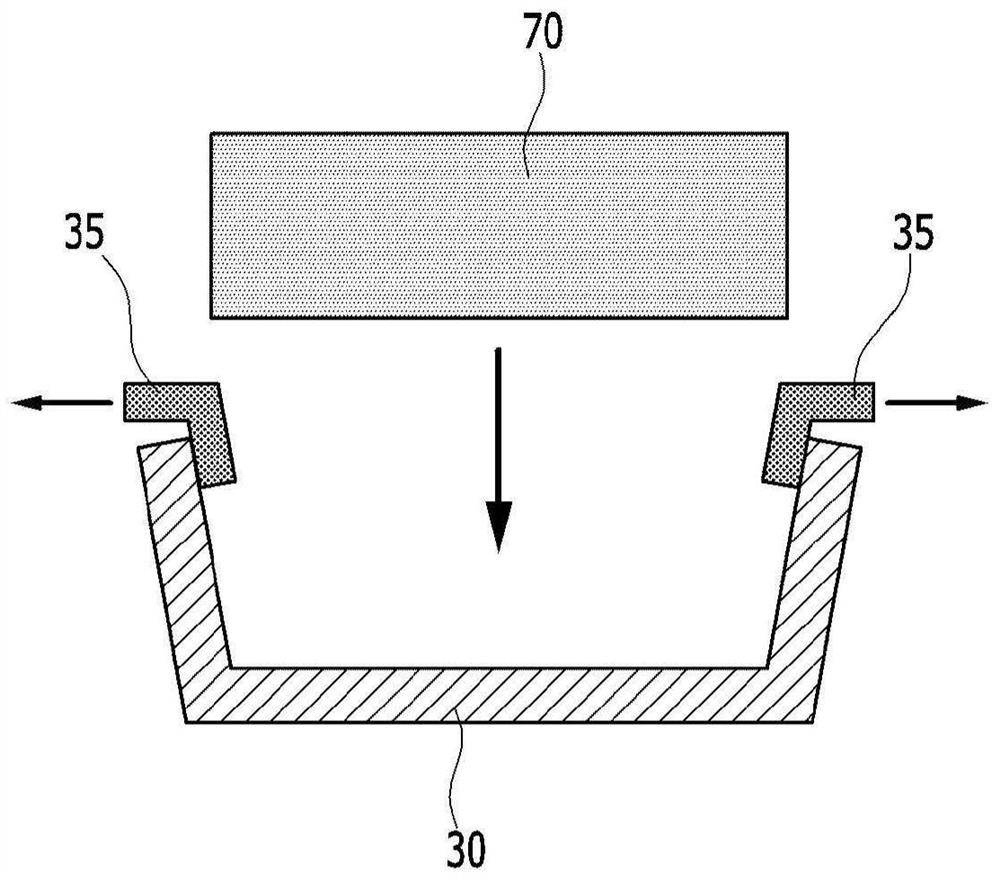

Embodiment Construction

[0033] Hereinafter, various embodiments of the present disclosure will be described in detail with reference to the accompanying drawings so that those skilled in the art can easily implement them. The present disclosure may be modified in various different ways and is not limited to the embodiments set forth herein.

[0034] Portions irrelevant to the description are omitted to clearly describe the present disclosure, and like reference numerals refer to like elements throughout the specification.

[0035] In addition, in the drawings, the size and thickness of each element are arbitrarily illustrated for convenience of description, and the present disclosure is not necessarily limited to those illustrated in the drawings. In the drawings, the thickness of layers, regions, etc., are exaggerated for clarity. In the drawings, the thicknesses of some layers and regions are shown exaggerated for convenience of description.

[0036] In addition, it will be understood that when a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com